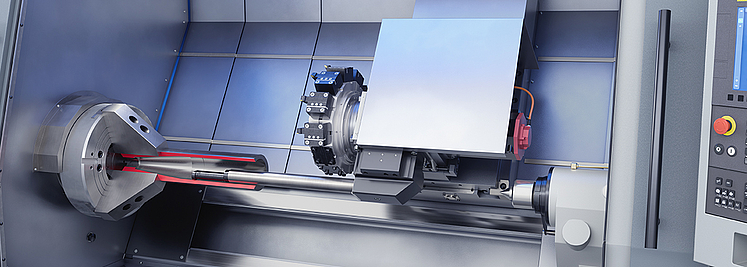

Precision turning of 155 mm artillery shells with the EMAG USC 850

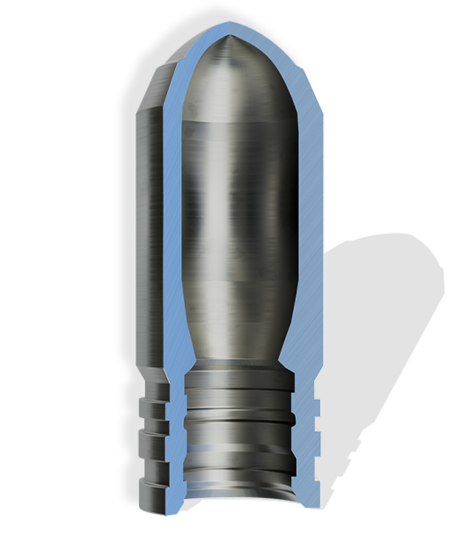

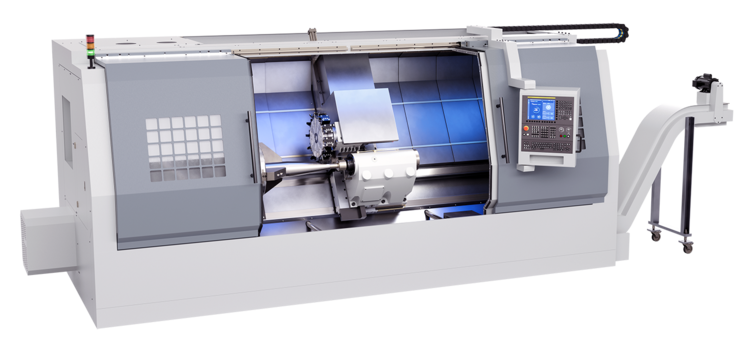

In the defense industry, maximum precision, reliability and efficiency are crucial. The USC 850 from EMAG fulfills these requirements exactly and enables the high-quality turning of 155 mm artillery shells.

Leading solutions for the defense industry: Maximum precision and performance

The USC 850 turning machine impresses with its generous machining area with a maximum turning diameter of 600 mm, specially optimized for 155 mm calibre artillery shells. A positioning accuracy of an impressive 0.009/0.018 mm and a roundness accuracy of ≤ 0.004 mm guarantee first-class ballistic properties of the machined ammunition. This technical accuracy is essential to meet the highest standards of safety and functionality.

Efficient machining of demanding materials

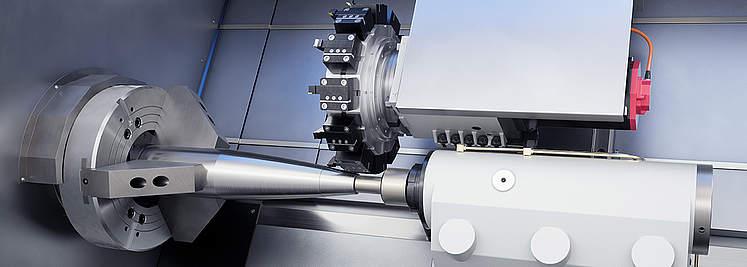

The USC 850 features an advanced 60° inclined bed design that offers outstanding static and dynamic rigidity. This reduces vibrations during the machining process to a minimum, which contributes significantly to the quality of the machined surface. The robust tailstock with a quill diameter of 150 mm ensures workpiece stability even with long and heavy artillery shells.

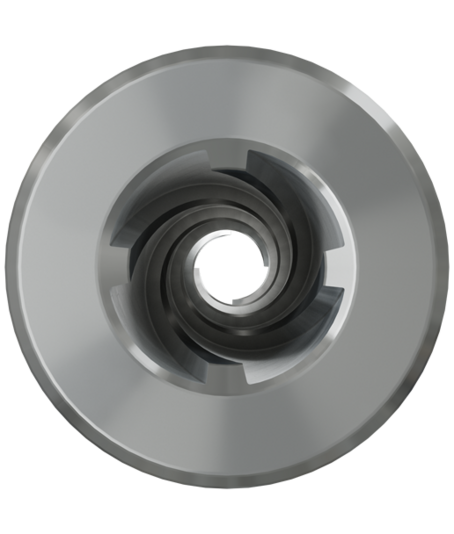

A turret with 12 stations and driven tools also allows flexible complete-machining in a single setup, minimizing time and costs. The integrated coolant supply directly to the cutting edge also ensures extended tool life and improved surface quality of the machined components.

The powerful main spindle of the USC 850 offers a continuous output of 30 kW and a peak output of up to 37 kW over 30 minutes. This allows efficient and fast machining of high-strength materials typically used in the defense industry. Thanks to special bearing combinations consisting of precision angular contact ball bearings and cylindrical roller bearings, the machine achieves a high spindle rigidity, which ensures consistently high precision even during heavy machining.

Optimized internal machining

Specially developed drilling/turning bars are used for the internal machining of the 155 mm shells. These tools can either be inserted manually into the tool receptors or exchanged using an automatic tool changer.

Fully automated solutions for your production requirements

EMAG offers integrated automation concepts that are tailored to your individual production requirements. The result is fully automated and efficient production lines that are specially tailored to the high safety and quality requirements of the defense industry. EMAG systems thus enable reliable, precision and economical machining of 155 mm artillery shells in both large and small batches.

Your advantages with the EMAG USC 850 at a glance:

- Maximum precision: Positioning accuracy up to 0.009 mm and roundness accuracy ≤ 0.004 mm

- Powerful machining: spindle power from 30 kW (continuous) to 37 kW (peak)

- Optimized process reliability thanks to 60° inclined bed design

- Flexibility in production thanks to turrets with driven tools

- Sustainable production processes through targeted coolant supply

- Customized automation solutions for maximum efficiency

Machines

(1) machines found