Classic – Universal Grinding – UG

UG Series

- Grinding length, max.: 1,500 mm | 59 in

- Center height: 175 / 225 mm | 7 / 9 in

- Workpiece weight, max.: 120 kg | 264.5 lb

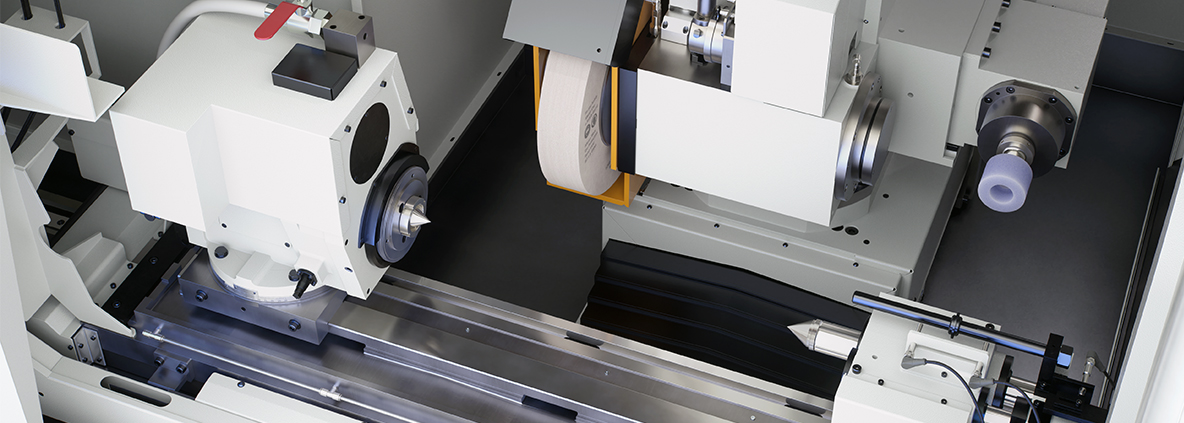

Universal cylindrical grinding machines for internal and external machining

The combination of a rigid machine base, high-quality EMAG components and proven grinding technology results in universal grinding machines that ensure economical machining with high dimensional accuracy and reproducibility.

UG Series Machines

| Machine | UG 400 | UG 630 | UG 1000 | UG 1500 |

|---|---|---|---|---|

| Grinding length | 400 mm | 630 mm | 1000 mm | 1500 mm |

This range enables users to choose the right solution for their needs - from precision toolmaking in workshops to universal production solutions.

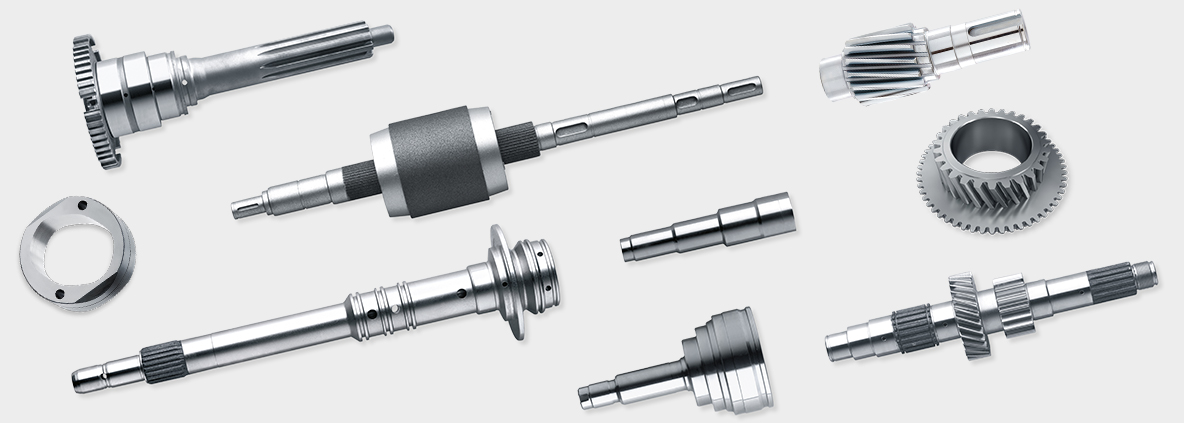

The UG Series: Versatile Solutions for a Wide Range of Workpieces

The universal grinding machines in the UG series are designed to handle a wide range of workpieces - from small precision components to long shafts and workpieces with complex geometries. Typical areas of application include tool and fixture construction, gear manufacturing and general precision engineering. Thanks to the flexible machine concept with internal, external and surface grinding options, multiple workpiece types can be machined in a single setup.

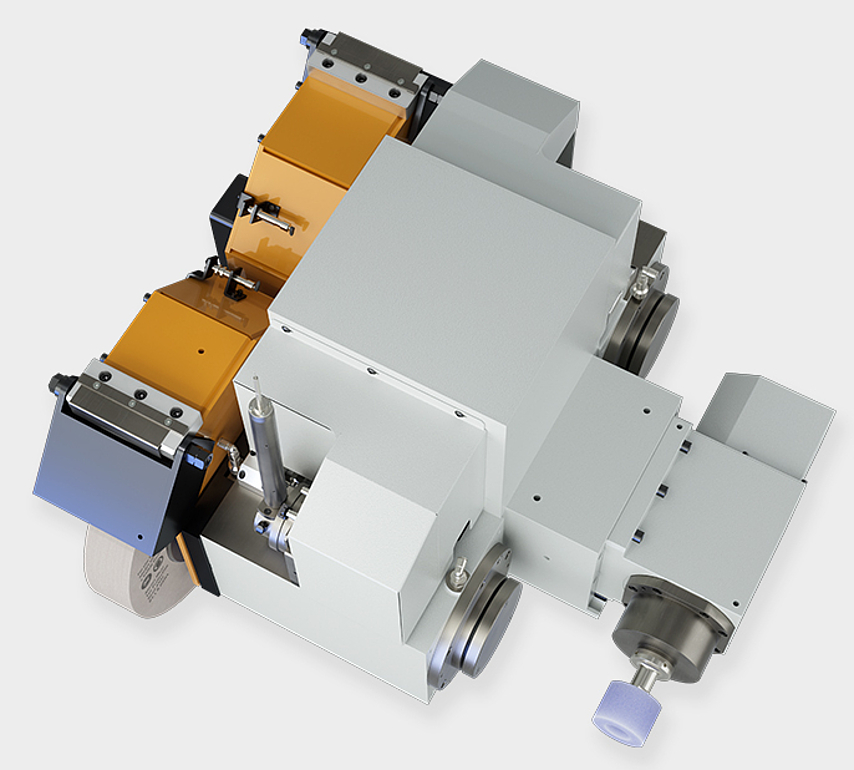

Grinding Head - Direct Drive and Precision

The grinding head of the UG machines is equipped with direct-drive motor spindles with an output of up to 11 kW. The direct drive eliminates the need for belts, reducing vibration and ensuring torque transmission without loss.

The B-axis swivels continuously and precisely, offering a positioning accuracy of ±2 angular seconds. With grinding speeds of up to 50 m/s, the machines support both conventional corundum wheels and CBN tools. Precision grinding spindles are used for internal machining.

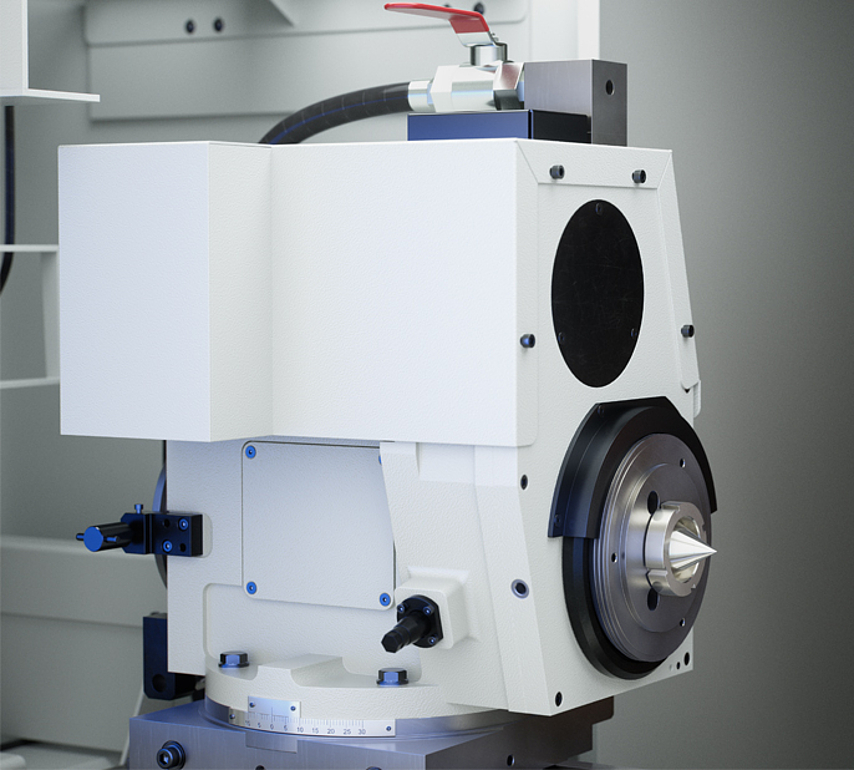

Workhead - Precise and Robust

The compact workhead spindle unit with precision tapered roller bearings ensures high rigidity and a roundness accuracy of 0.5 µm on the test workpiece. The swivel range of 0 to +30° enables flexible machining. A pneumatic lifting device facilitates set-up and positioning. AE sensors (structure-borne sound sensors) can be integrated as an option to detect contact between the grinding wheel and workpiece – reducing idle times and increasing productivity.

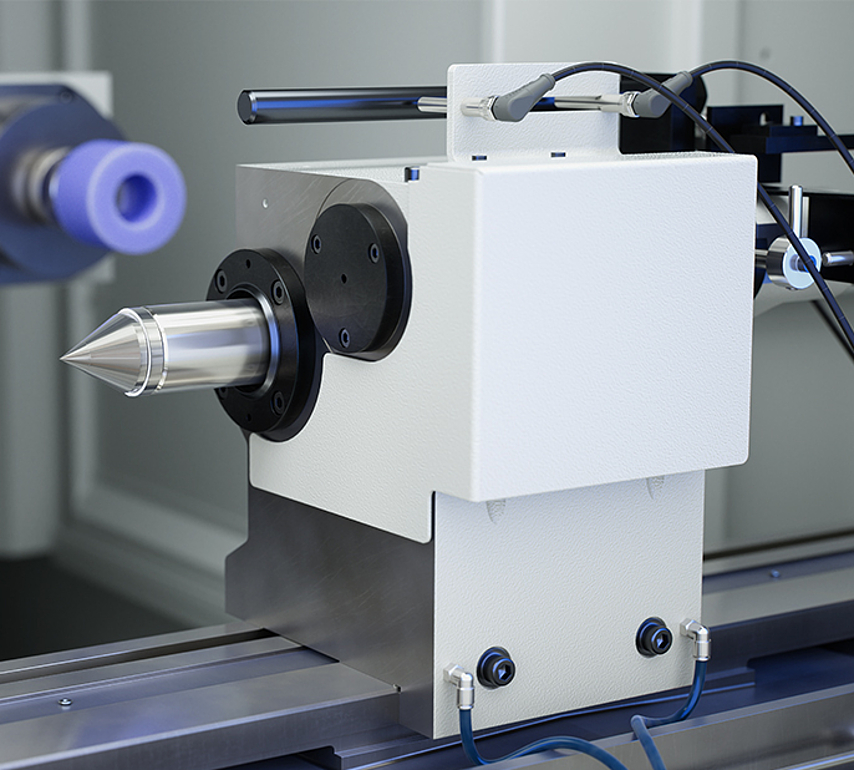

Tailstock - High Accuracy for Centering

The tailstock features a quill Ø 63 mm for MK4 centers and runs with minimal backlash in the guide. A fine adjustment of ±40 µm enables the exact correction of taper deviations and achieves concentricity accuracies of less than 1 µm.

Manual or hydraulic actuation systems are available. The hydraulic reset accelerates workpiece changeover, while the pneumatic lifting function simplifies set-up. Integrated sensors monitor the correct workpiece position and increases process reliability.

Dressing Systems - Flexible and Reliable

A variety of dressing systems are available to meet different requirements, whether using a stationary dresser or a dressing spindle:

- Table-mounted swivel arm dresser for flexible positioning and universal profile dressing

- Dressing system on the workpiece headstock for direct integration into the machining process

- Dressing system on the tailstock for special applications

These modular solutions ensure consistent grinding conditions and uniform surface quality - regardless of the workpiece type.

Control and operation

The UG machines are equipped with the FANUC 0i-TF Plus CNC control. It offers a dialog-oriented HMI for simple programming and operation. The FANUC 31 iB Plus with increased computing power is available for complex contours, especially in out-of-round grinding.

FANUC controllers are available worldwide, which guarantees excellent service availability, short response times and spare parts reliability - a decisive advantage in international use.

Advantages UG Series

- High precision through a rigid machine base design

- Universal capability for internal, external, out-of-round and face-grinding.

- Direct drive technology ensures low-vibration operation and consistent machining quality.

- Swiveling B-axis enables flexible grinding strategies and complex workpiece geometries.

- FANUC control provides an intuitive user interface and high programming flexibility.

- Modular dressing systems guarantee reproducible surfaces and consistent dimensional accuracy.

- Integrated sensors monitor process parameters and detect contact between tool and workpiece.

- Pneumatic and hydraulic functions allow for quick set-up and efficient workpiece changeover.

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Finding the right balance between flexibility and productivity is challenge of designing machines for cylindrical grinding.

This demand is met with…

Out-of-round grinding with CBN grinding technology allows high-precision machining of cams, camshafts, pump rings and other components with…

Universal cylindrical grinding generally refers to the cylindrical grinding process applied to the outside or inside diameter of a part. For external…