Tube Sleeve Machining Centers

USC 21

- Nominal diameter: Inch 2 ⅜ – 20

- X-axis travel: 350 mm | 14 in

- Z-axis travel: 600 mm | 23.5 in

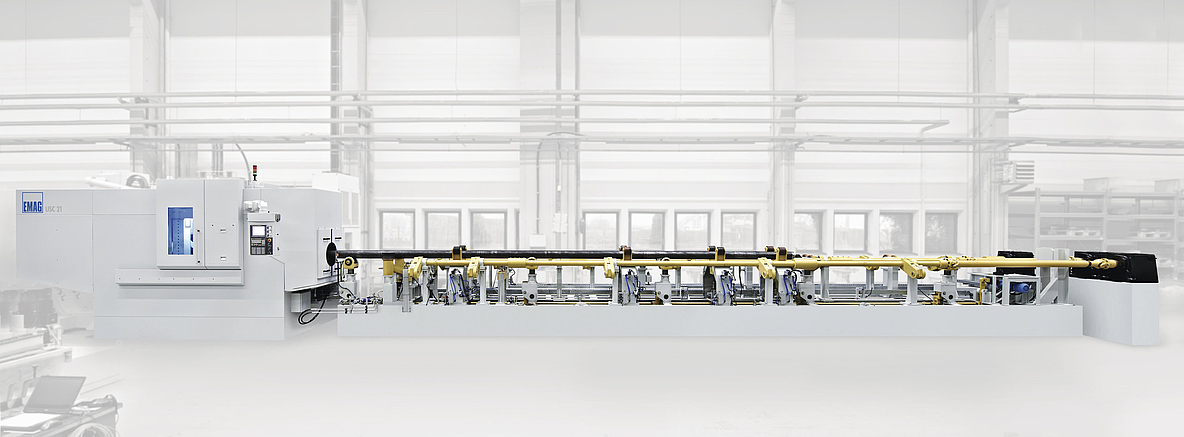

The Pipe Threading Machine USC 21 – For the flexible machining of pipe ends

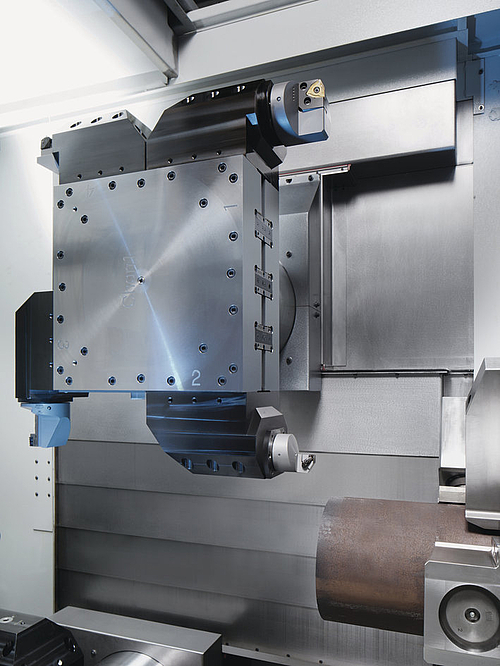

A distinct feature of the USC 21 Pipe Threading Machine is its MINERALIT® Construction, which is more resistant to vibration than any other concrete base. Allowing for less vibration during operation, this ensures proper alignment and a more precise threading job.

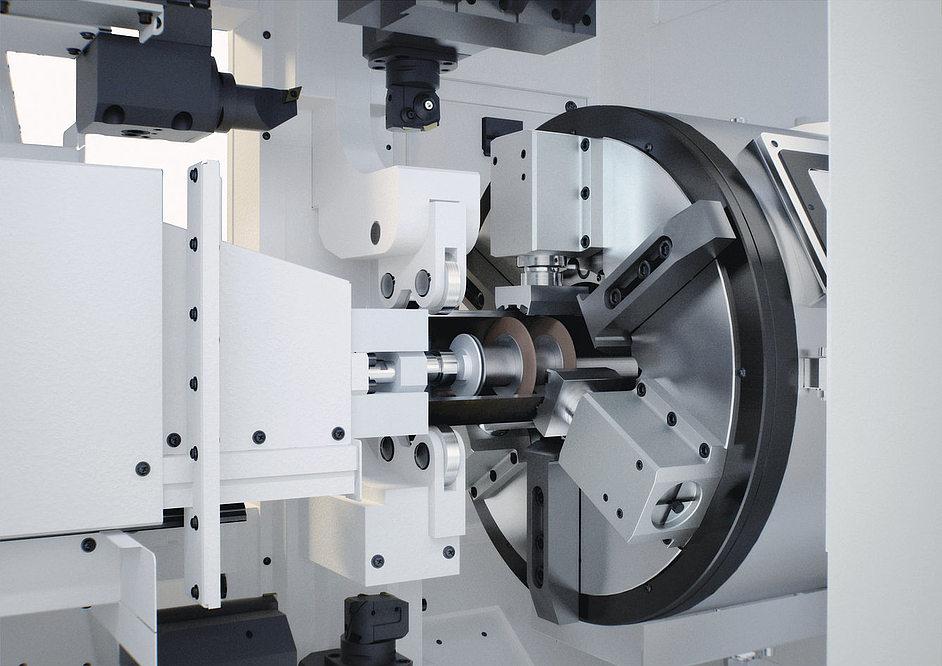

Lesser vibration also lengthens the life of the machine and its parts. Both internal and external machining operations can be carried out on this Pipe Threading Machine. This machine concept is designed for the complete-machining of all popular threads, API and GOST standard and all proprietary threads, including integral joints.

Machining of premium threads on OCTG components, whether they are international (API, GOST) or a

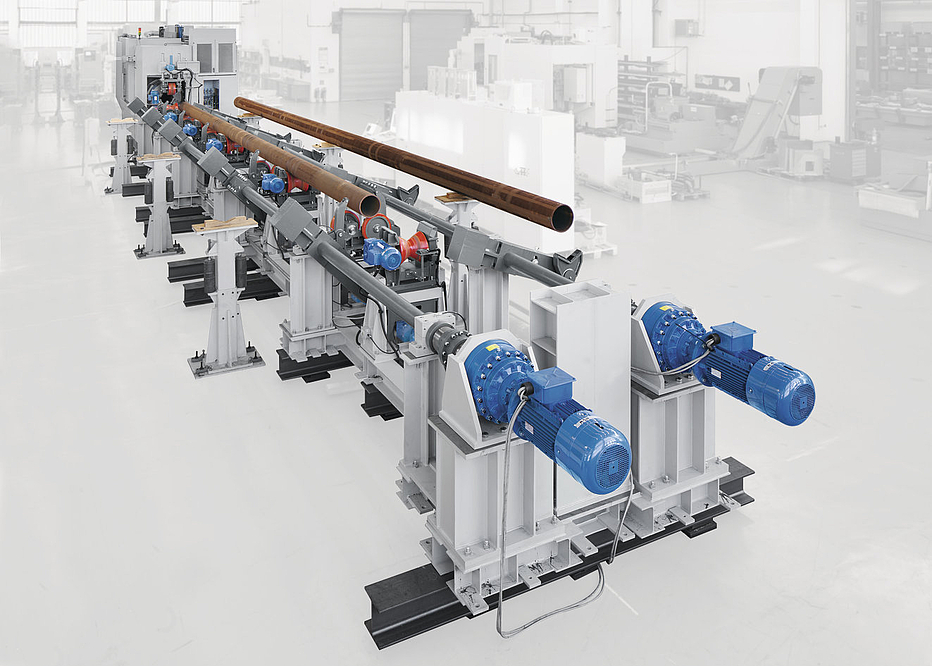

The concept behind the USC 21 Pipe Threading Machine is a design special for the machining of pipe ends. It combines all the features prerequisite for quality, durability and productivity, with a flexibility that covers all the applications for standard and premium threads. All pipe diameters, ranging from 2 3/8” to 20”, can be machined with the best technological and customized conditions through the choice of 5 spindle sizes. The USC 21 Pipe Threading Machine is modular and can be executed as a 2-axis-, 4-axis and 6-axis-machine concept.

Additional axes accommodate the unit for external and internal centering, the pipe stop,and the setting unit for the removable plug. For integration into complete machining lines both left and right versions are available, as well as a choice of control systems. The USC 21 Pipe Threading Machine is designed for API and GOST-threading and really shows itsstrength in the machining of premium threads. Furthermore, copy-plan-and bevel-processing applications are as important as the processing of hydraulic cylinders and pistons.

Advantages USC 21

- Modular design

- The ideal platform for multifunctional manufacturing solutions – single- and multi-spindle – up to fully automated production systems

- Very sturdy, vibration-resistant machine base of high quality MINERALIT® polymer concrete

- Powerful, direct-driven spindle motors

- Direct-indexing tooling systems

- High-precision, preloaded linear roller guides for maximum precision and great dynamic

- Absolute position feedback systems for constantly maintained precision

- Fluid-cooled, temperature-controlled main assemblies – including spindle motor, tooling systems and electrical cabinet – form the basis for high quality workpieces

- Safe, wear resistant, maintenance free machining area

- Ideal chip flow conditions, with the chips downward unhindered, causing no damage

Technical Data

Nominal diameter

2 ⅜ – 20 Inch

X-axis travel

350 mm

14 in

Z-axis travel

600 mm

23.5 in

| Nominal diameter | Inch | 2 ⅜ – 20 |

| X-axis travel |

mm

in |

350

14 |

| Z-axis travel |

mm

in |

600

23.5 |