Customized – Chucked Components – VLC/VSC/VST

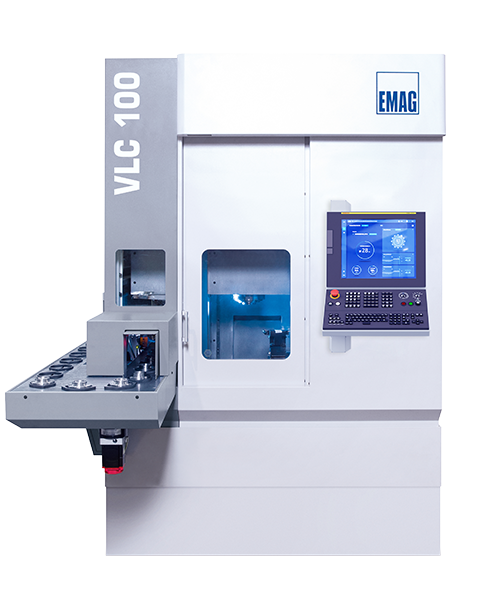

VLC 100

- Workpiece dia., max.: 100 mm | 4 in

- Workpiece length, max.: 150 mm | 6 in

- Chuck dia., max.: 160 mm | 6.5 in

The VLC 100 – Flexible CNC Turning Machine Available With a Range of Technologies

The VLC 100 is a CNC turning machine with a modular structure that allows it to be configured for a wide variety of applications. Whether turning, grinding, milling, or gear hobbing — the CNC lathe can be flexibly equipped with virtually all the technologies of the EMAG Group.

The VLC 100 CNC Turning Machine for High-volume Production of Chucked Parts

The VLC 100 is the ideal CNC turning center for producing chucked parts up to 100 mm in diameter. The modular VL 2 machine already offers a wide range of configuration options, but with the VLC 100 there are essentially no limits to what the user can do. Technologies from the full portfolio of the EMAG Group can be installed on the VLC 100, making it one of the most versatile vertical CNC turning machines in the EMAG machine catalog. The VLC 100 is useful in any application where very high requirements are placed on the manufacture of parts.

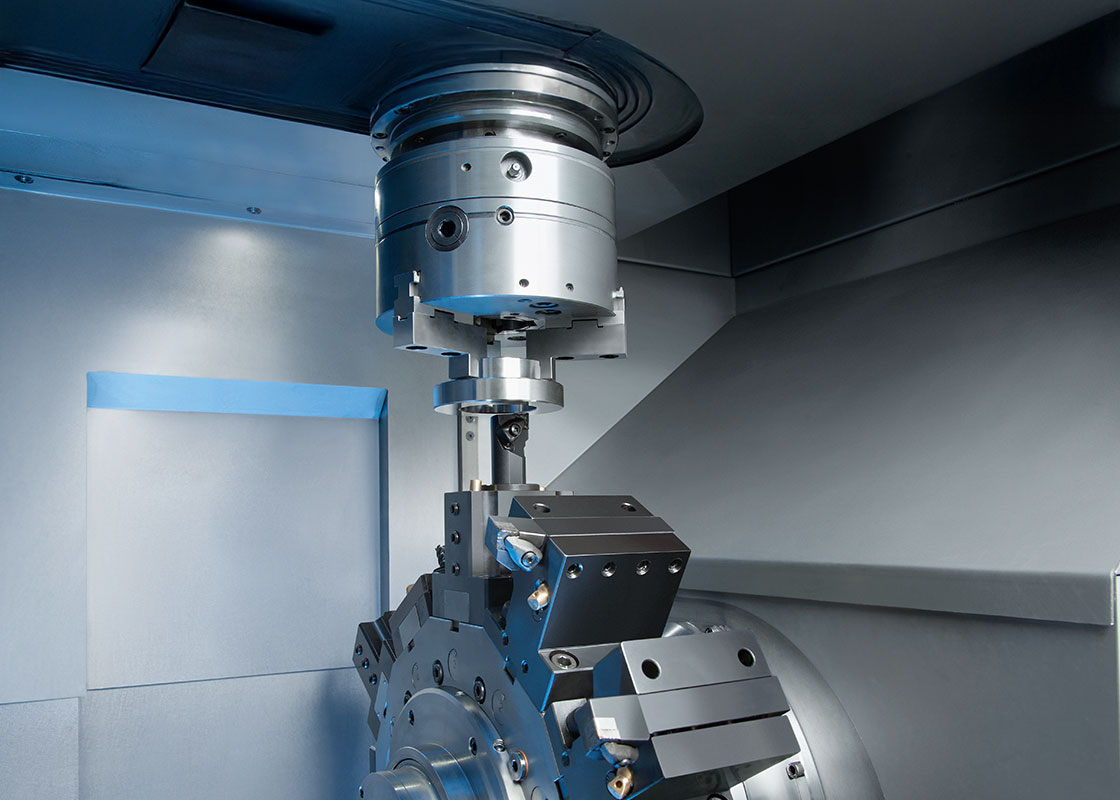

Integrated pick-up automation system

The CNC turning machines in the VLC series are equipped with a pick-up spindle that loads parts from the integrated conveyor belt and feeds them into the machining area—the short distance makes for shorter chip-to-chip times. The machining area can be configured flexibly and the tool turret, with its twelve tool positions, can be equipped with driven tools and stationary tools for the turning process.

A few of the available technology modules

- 12-position tool turret

- Out-of-round turning unit

- Horizontal drilling/milling units

- Swiveling axes for milling and drilling

- Hard turning (block tool holder)

- Combined hard turning + OD grinding

- Combined hard turning + ID + OD grinding

Advantages VLC 100

- Machine can be customized to processing requirements

- Wide range of technology modules available for selection

- Ideally prepared to meet any customer requirements

- Perfectly adaptable and therefore ideal for integration into existing manufacturing systems

- Customized automation solutions available

- Small footprint reduces floor space costs with flexible options for machine positioning

- Short distances for part transport optimally minimize non-productive times

- User-friendliness (easily accessible machining area) for faster setup and safe operation with the option of compact alternative layouts

- High energy efficiency for lower energy costs

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

The combination of a number of processes – such as hard turning and grinding – on a single machine, allows for the exploitation of considerable…

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

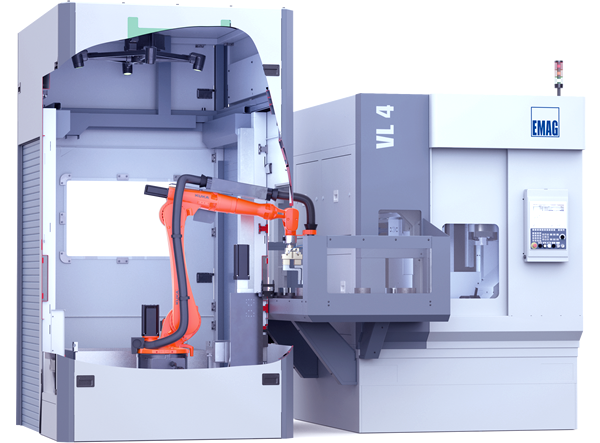

Automation Solutions

Complete Manufacturing Lines or Automation Systems from EMAG

Technical Data

Workpiece dia., max.

100 mm

4 in

Workpiece length, max.

150 mm

6 in

Chuck dia., max.

160 mm

6.5 in

| Workpiece dia., max. |

mm

in |

100

4 |

| Workpiece length, max. |

mm

in |

150

6 |

| Chuck dia., max. |

mm

in |

160

6.5 |

| Swing diameter |

mm

in |

210

8.5 |