Laser Cleaning Machines

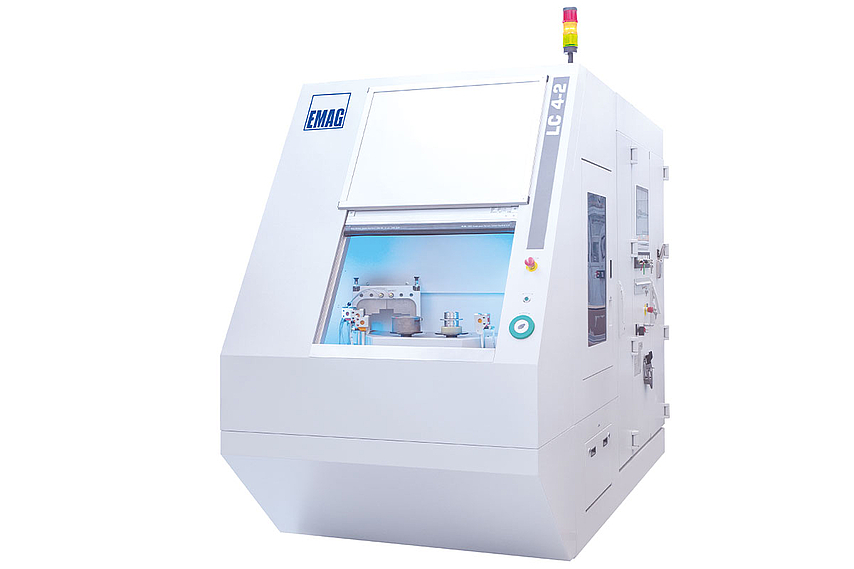

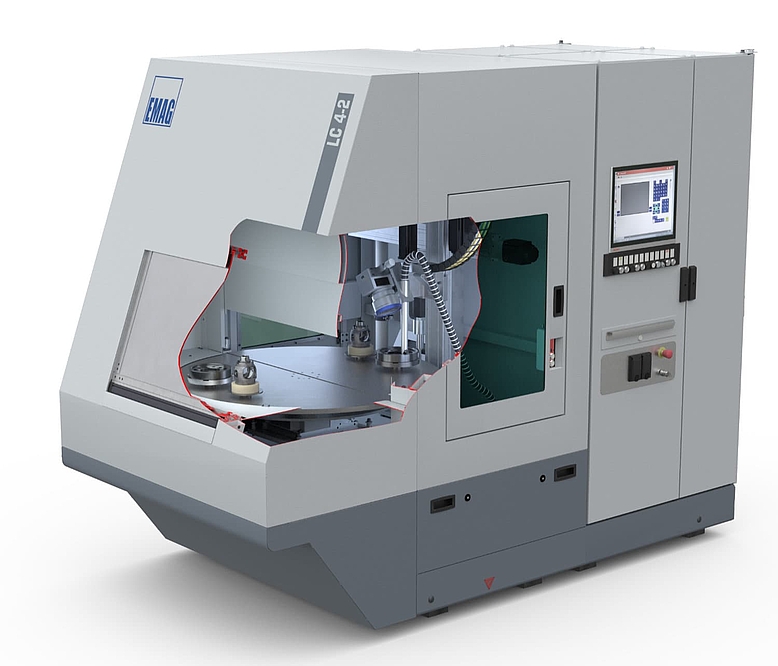

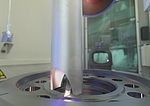

LC 4-2

- Footprint: mm 1500 x 3050

- Laser capacity: 200 W fibre laser

- Max. axis speed (rapid-traverse) X / Z axis: m/s 0,4 / 0,5

Standalone LC 4-2 laser cleaning machine for implementation in manufacturing lines or as a standalone machine

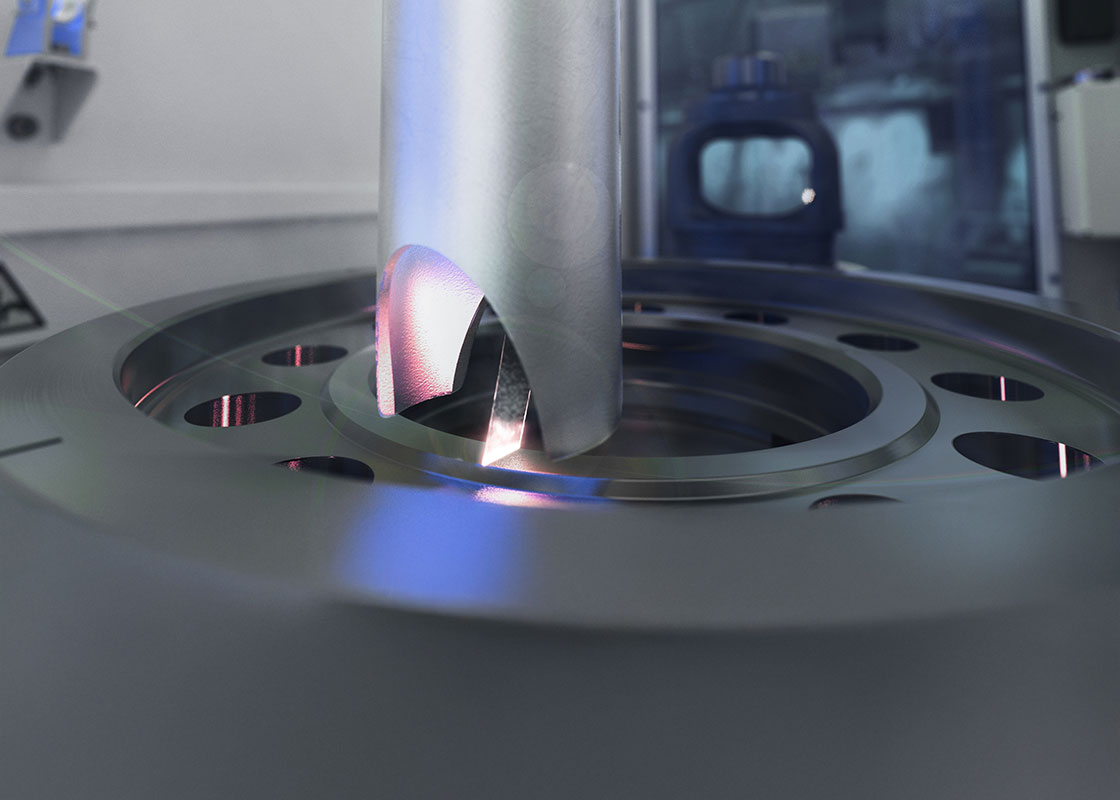

The LC 4-2 laser cleaning machine evaporates impurities on surfaces using a high-energy laser beam. The machine is designed for components with a max. diameter of 200 mm and a max. height of 350 mm.

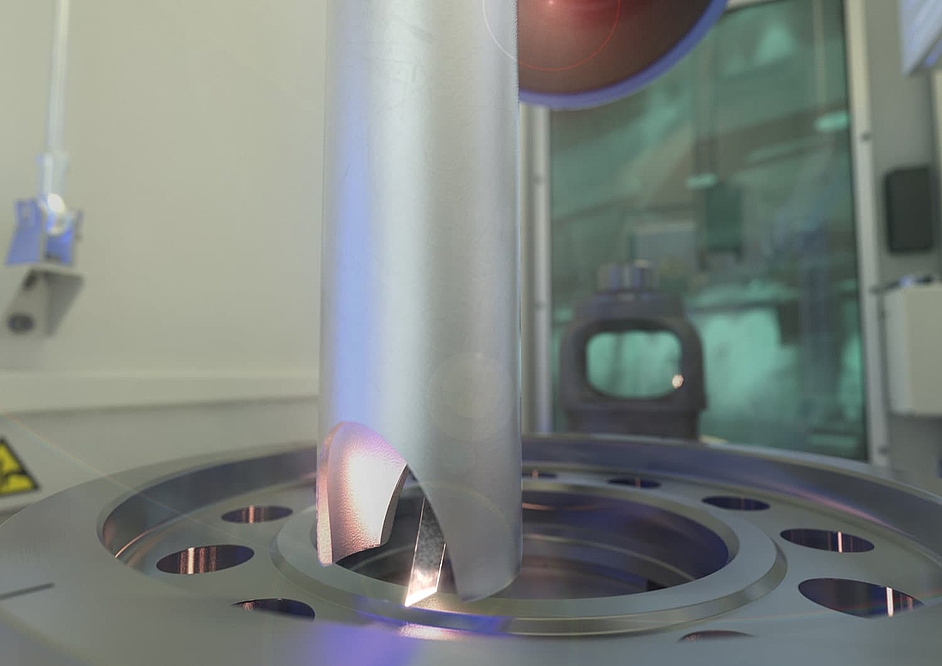

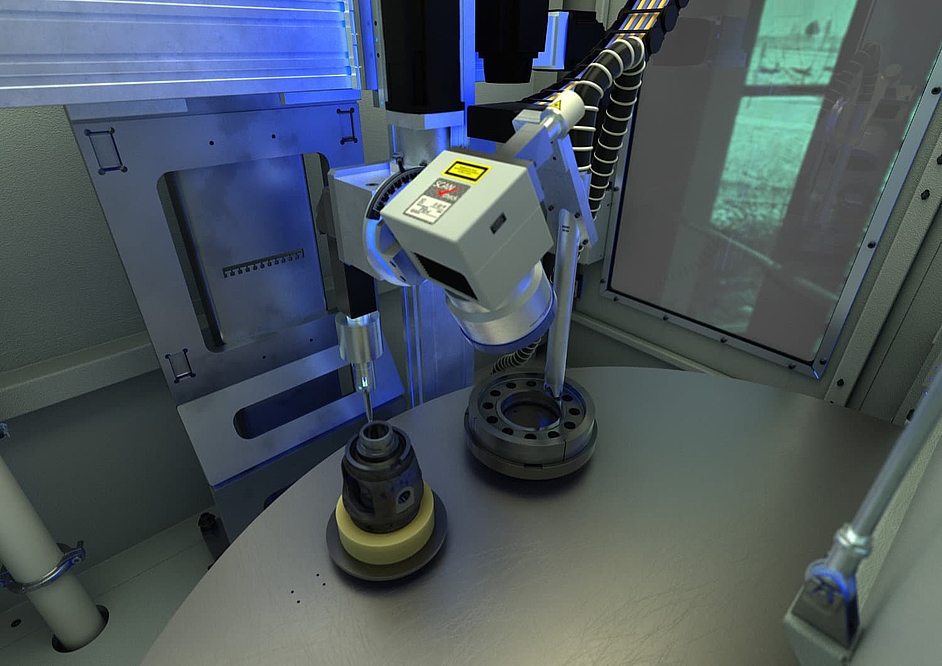

Laser cleaning in detail

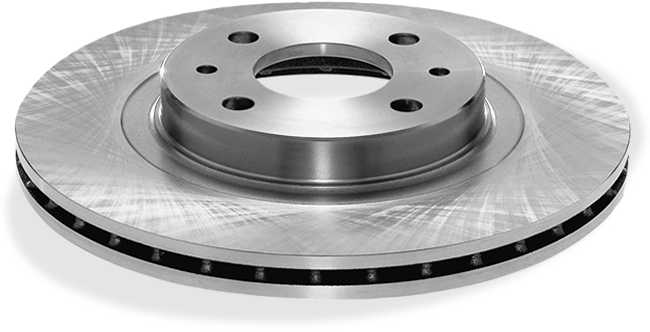

Laser beam cleaning is a method that, for quite some time now, is no longer solely implemented for mold cleaning, but that can also be implemented to clean a wide range of different components during processing. The success of the laser as an alternative to conventional cleaning methods can be attributed to the numerous advantages of the process. For one, the method only incurs very low operating costs, since no cleaning agents are used and no waste disposal is required. Secondly, the process is very precise and gentle on surfaces. Finally, the excellent cleaning results that can be achieved with the laser beam are ultimately the decisive factor. The laser evaporates oxides, dirt particles of all kinds and above all impurities from polymer-based lubricants, which are particularly difficult to remove, in a matter of seconds. The remaining surface is perfectly prepared for subsequent machining, e.g. laser welding.

Advantages LC 4-2

- Energy-efficient: lower energy consumption than conventional washing units

- Reliable: no additional contamination from cleaning agent residues; practically maintenance-free

- Fast: no parts traveling around the plant and lengthy non-productive times, since laser cleaning can be fully integrated into the laser systems

- Quality: all typical organic residues are removed

- Very cost-efficient

- Stable process: not dependent of water quality or its additives

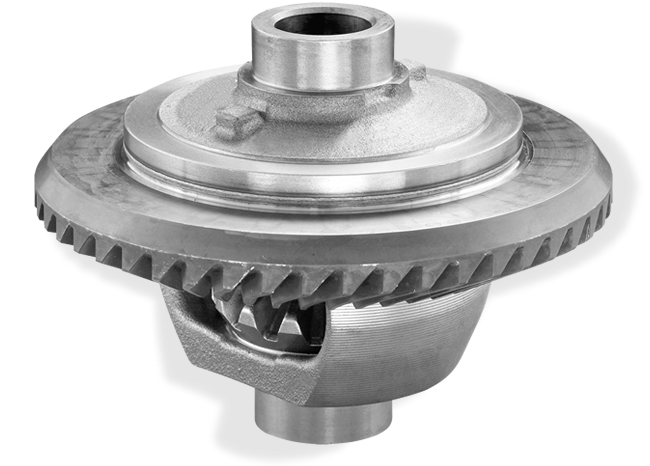

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Laser cleaning is a fast and space-saving process that can replace conventional washing machines in many applications. One of its main strengths is…

Technical Data

Footprint

1500 x 3050 mm

Laser capacity

200 W fibre laser

Max. axis speed (rapid-traverse) X / Z axis

0,4 / 0,5 m/s

| Footprint | mm | 1500 x 3050 |

| Laser capacity | 200 W fibre laser | |

| Max. axis speed (rapid-traverse) X / Z axis | m/s | 0,4 / 0,5 |