Classic – Conventional Grinding – ECO

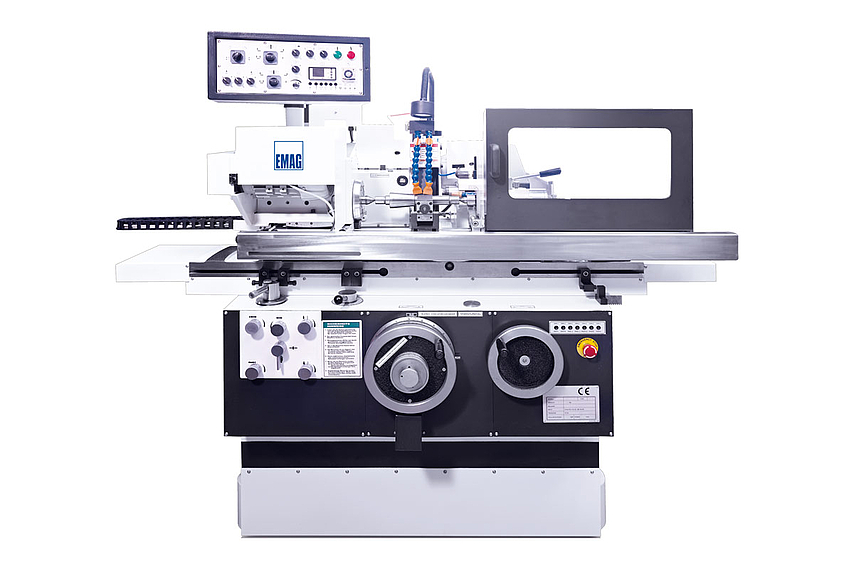

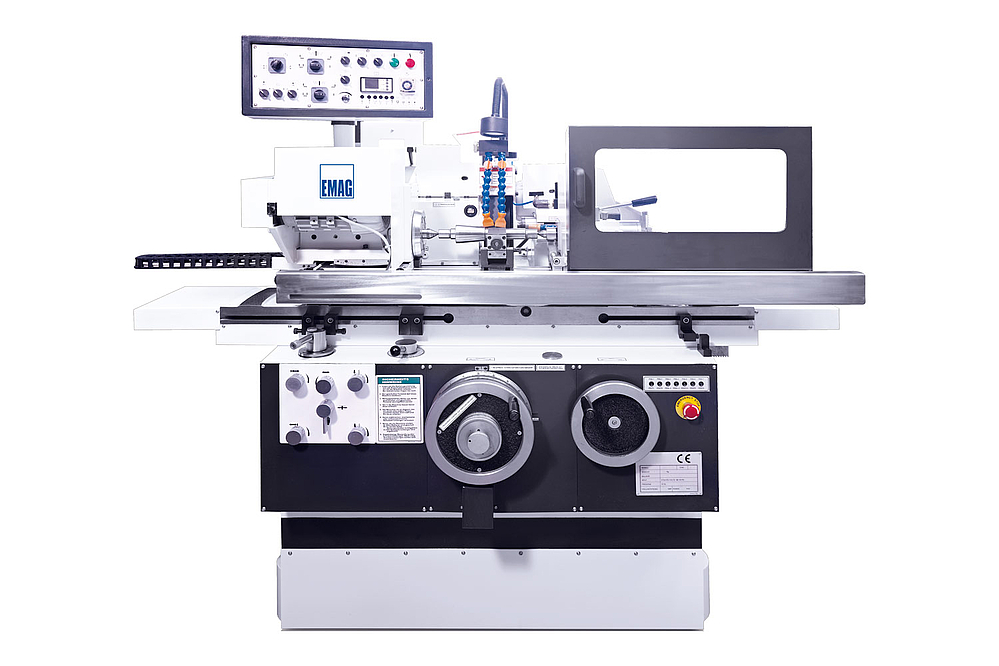

ECO 200

- Grinding length, max.: 400 mm | 15.5 in

- Center height: 100 mm | 4 in

- Grinding Ø external: 1 / 100 mm | 0 / 4 in

ECO 200 - Compact, Conventional Cylindrical Grinder

The conventional cylindrical grinder ECO 200 delivers EMAG Weiss grinding quality, while minimizing investment costs. This precision cylindrical grinder is targeted to users who do not require a CNC control unit, but still set the highest requirements for machining quality.

ECO 200 - cost-effective, precision cylindrical grinder for the smallest workpieces

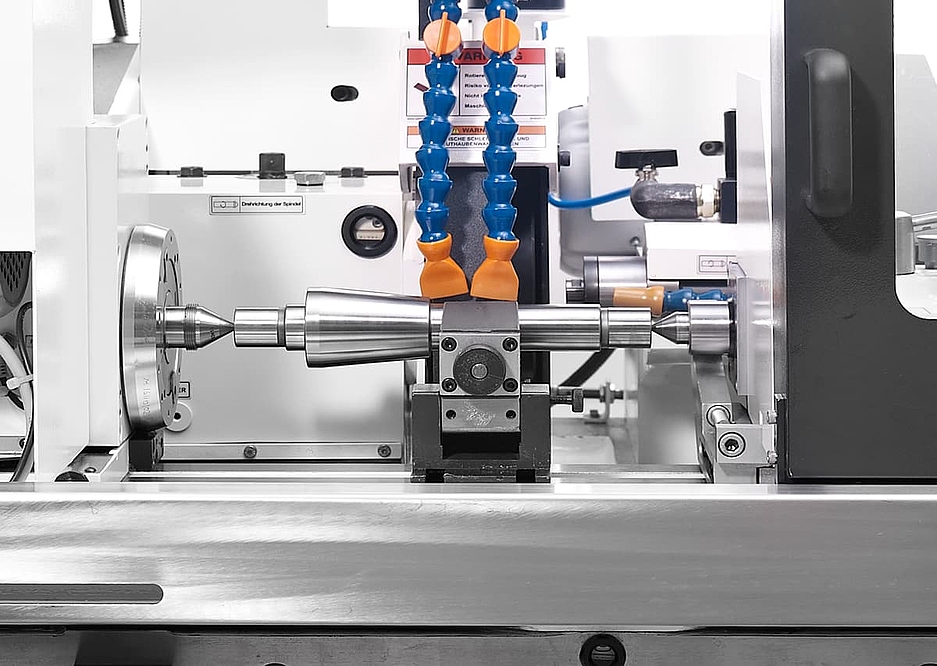

The ECO 200 is a simple, cost-effective, precision cylindrical grinder with a tip width of 400 mm (16 in) and a tip height of 100 mm (4 in). The machine is easy to operate and access, which allows for fast machine tooling. The grinding headstock has a drive rating of 3.7 kW (5 hp) and can hold grinding wheels of up to 350 mm (14 in) in diameter. The workpiece headstock has an MK4 socket and enables continuous speed adjustment up to 500 rpm at a drive rating of 0.28/0.37 kW . The tailstock has an MK3 socket with a quill stroke of 25 mm (1 in).

An internal grinding device featuring a spindle socket of 60 mm (2,36 in) in diameter and with a drive rating of 1.5 kW (2 hp) is also available.

Advantages ECO 200

- Low investment cost

- Easy operation

- Easy retooling

- Simple machine concept

- Small footprint

Precision cylindrical grinding

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

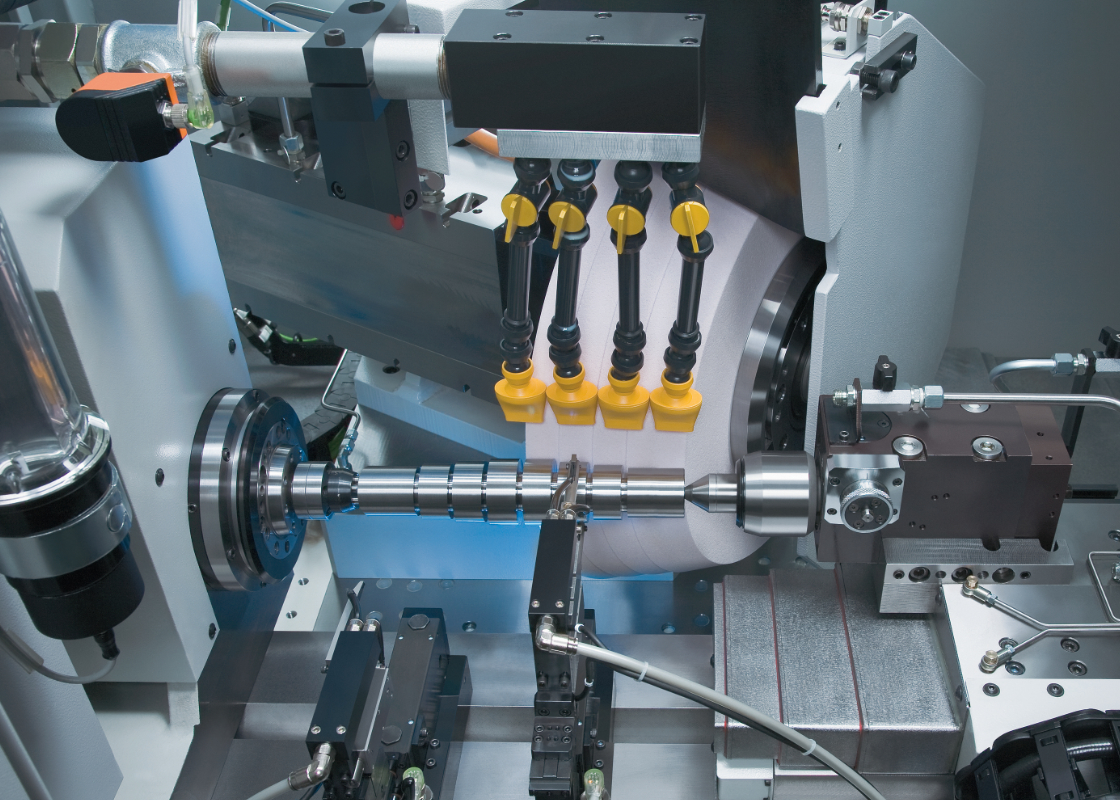

Universal cylindrical grinding generally refers to the cylindrical grinding process applied to the outside or inside diameter of a part. For external…

Technical Data

Grinding length, max.

400 mm

15.5 in

Center height

100 mm

4 in

Grinding Ø external

1 / 100 mm

0 / 4 in

| Grinding length, max. |

mm

in |

400

15.5 |

| Center height |

mm

in |

100

4 |

| Grinding Ø external |

mm

in |

1

/ 100

0 / 4 |

| max. workpiece weight floating MK4 |

kg

lb |

10

22 |