Gear Profile Grinding Machines

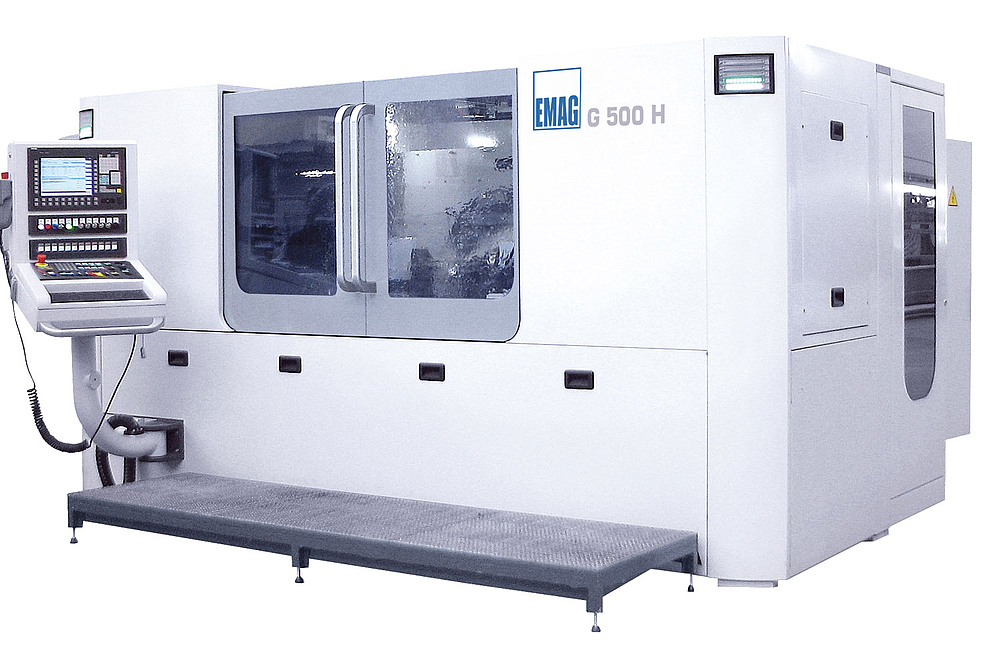

G 500 H

- Module range: mm 0.5 – 22.0

- Workpiece dia., max.: 500 mm | 19.5 in

- Workpiece length, max.: 1,250 mm | 49 in

Gear Profile Grinding G 500 H

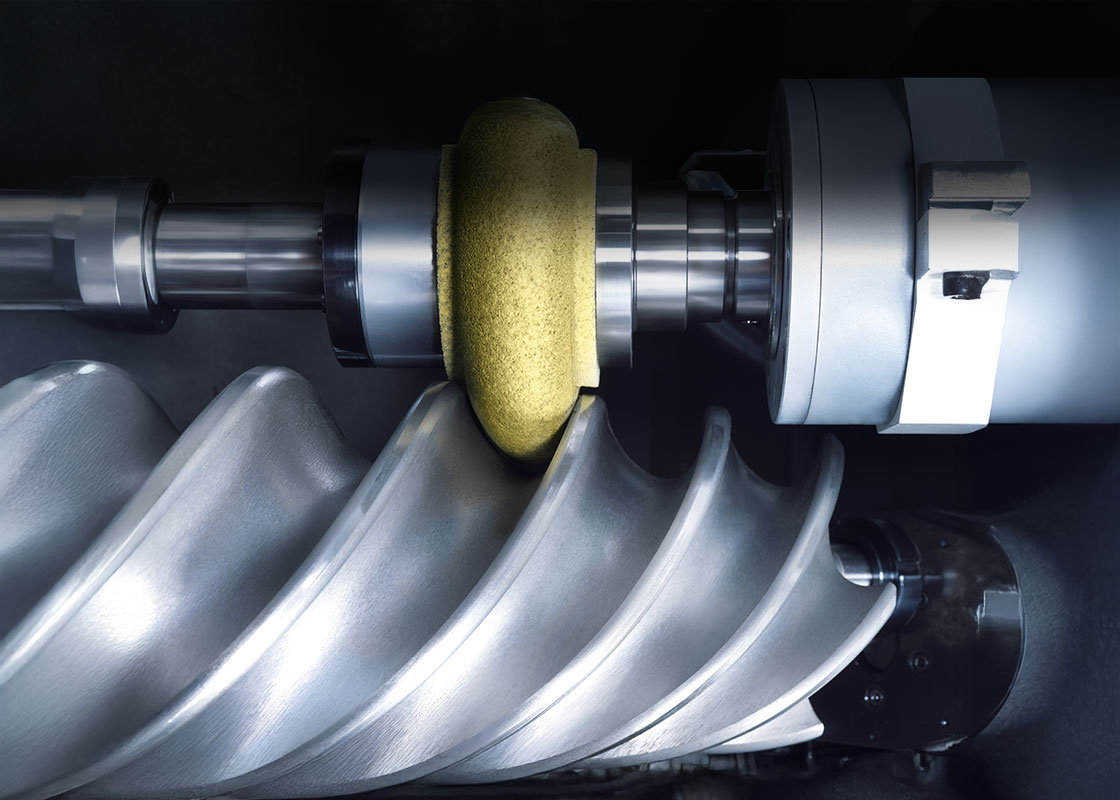

The G 500 H gear grinding machine is ideal for single pass creep feed grinding of external spur and helical gears, crown gears and shafts, worms, rotors and screw.

G 500 H Gear Grinding Machine: Flexible and Universal

The G 500 H gear grinding machine is the universal and extremely flexible base machine of the EMAG SU gear profile grinding machine Series.

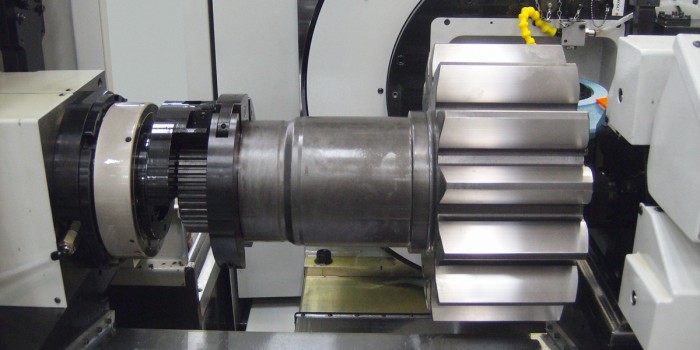

It is ideal for single pass grinding of external spur and helical gears, trapezoidal screws, crown gears and shafts, worms, rotors and screw-type workpieces up to 500 mm in diameter and a workpiece length of 2,150 mm. Optionally it is possible to grind spur or helical internal gears.

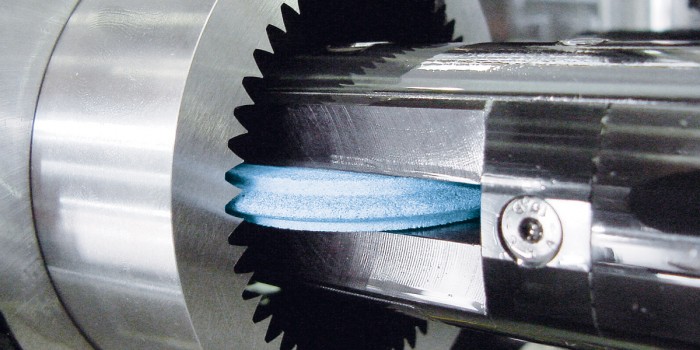

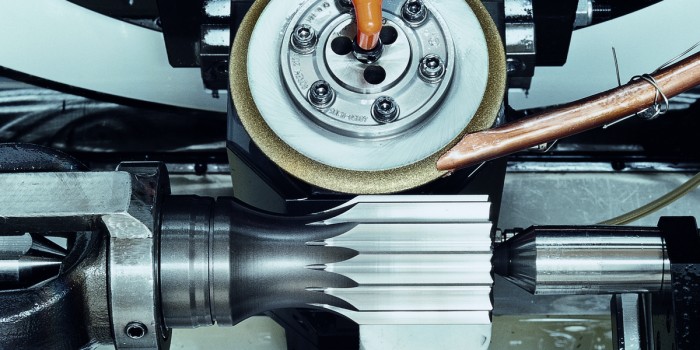

Quick-change spindles for internal and external grinding and ceramic tool technology, combined with a flexible dressing unit and modular software packages guarantee rapid format change and unmatched process versatility.

Also electroplated CBN wheels and dressable CBN wheels can be used on this gear profile grinding machine. Extreme small grinding wheels can be used, internal grinding wheel starting from 26 mm, external wheel from12 up to 360 mm in diameter by using different spindles.

Advantages G 500 H

- Universal solution for a wide range of gears, shafts and screw-type workpieces

- Flexible manufacturing of small or large batches

- Grinding from the solid

- 5 different standard grinding spindles for external grinding and 4 for internal grinding

- Integrated checking for internal and external gears

- Automation possible

- Tool changes as an option

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Profile grinding of gears and long, slim and toothed components is performed discontinuously, i.e., tooth gap by tooth gap, is completed one after the…

Technical Data

Module range

0.5 – 22.0 mm

Workpiece dia., max.

500 mm

19.5 in

Workpiece length, max.

1,250 mm

49 in

| Module range | mm | 0.5 – 22.0 |

| Workpiece dia., max. |

mm

in |

500

19.5 |

| Workpiece length, max. |

mm

in |

1,250

49 |

| Centre dist. work spindle / tool spindle |

mm

in |

20

/ 445

1 / 17.5 |

| Tool spindle power |

kW

hp |

20

27 |