02/12/2026 - Oliver Hagenlocher - Press

EMAG UG Series - Universal grinding machines for precision manufacturing tasks

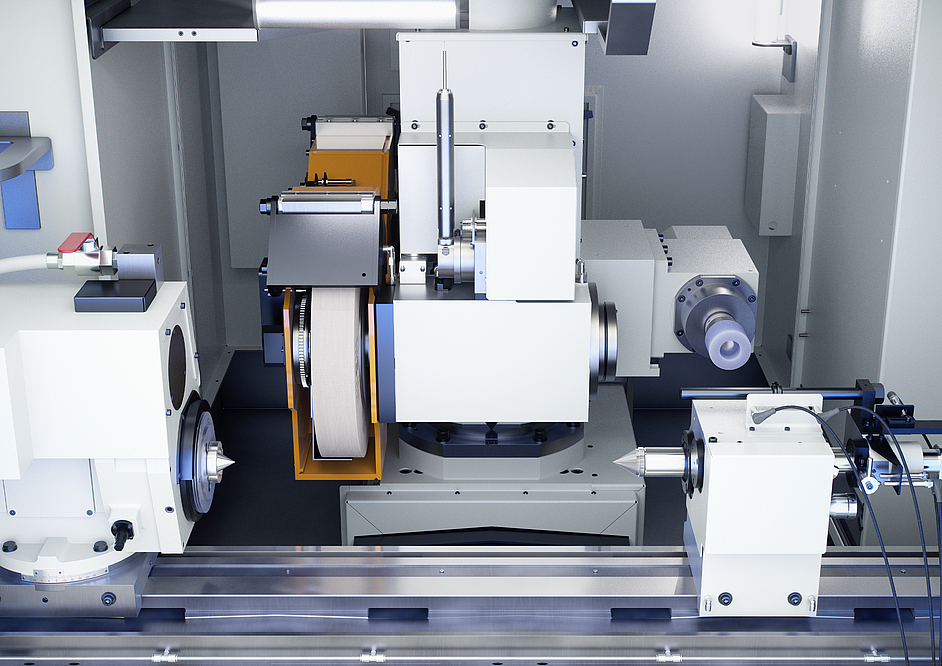

The universal grinding machines in the UG Series combine proven grinding technology with a cost-efficient machine base. They are ideal for users who are looking for a sophisticated solution for internal, external and out-of-round grinding and do not want to compromise flexibility, precision and process reliability.

The UG Series include machines with grinding lengths from 400 to 1,500 millimeters. This gradation covers a wide range of requirements - from compact workshop machines for toolmaking to universal production solutions for longer shafts and complex geometries - whether clamped between centers or in a chuck.

Images

Model overview and range of applications

The series is divided into four variants:

- UG 400 with 400 mm grinding length

- UG 630 with 630 mm grinding length

- UG 1000 with 1,000 mm grinding length

- UG 1500 with 1,500 mm grinding length

Linear guides in the X and Z axes, servo drives with recirculating ball screws and direct-drive motorized grinding spindles form the technical basis. The standard center height is 175 mm and the maximum workpiece weight is 120 kilograms (model UG 1000). Larger center heights and workpiece weights are possible with additional equipment.

Grinding head - precision through direct drive

The grinding head is equipped with direct-drive motor spindles. The spindle power is up to 11 kilowatts. As there is no belt drive, there are no sources of vibration, and the torque is transmitted without loss. This leads to uniform power transmission and reduces vibrations during the grinding process.

The automatically swiveling B-axis enables infinitely variable positioning between -15° and +225° with an accuracy of 0.0005 degrees. This precision is required for surface and contour grinding, where the exact angular position of the grinding wheel determines the machining result. The achievable peripheral speed of the grinding wheel is 50 meters per second. Precision grinding spindles are used for internal machining. These spindles are characterized by high motor speeds and a robust bearing with oil-air lubrication, which is required for internal grinding of small bores.

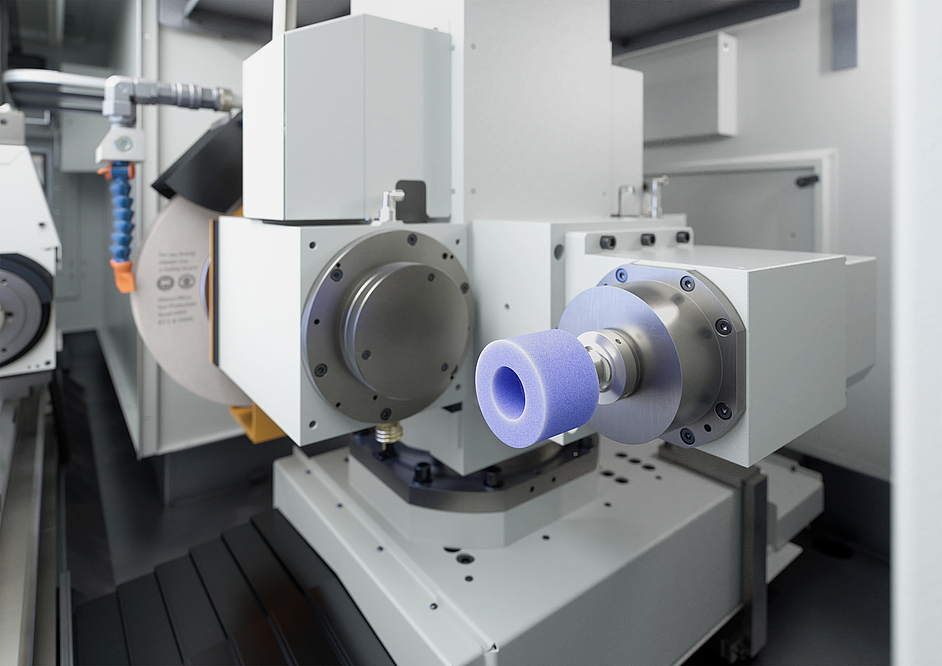

Workhead - rigidity and concentricity

The workhead is equipped with precision tapered roller bearings that ensure high rigidity. The concentricity accuracy on the test workpiece is 0.5 micrometers. This accuracy is the result of the rigid bearings and the quality of the components used.

A swivel range of 0° to +30° enables various grinding strategies for cone grinding. A pneumatic lifting device facilitates set-up and positioning of the workpiece. AE sensory equipment can be integrated as an option. These sensors detect the contact between the grinding wheel and workpiece and reduce idle times.

An optional workpiece spindle with C-axis is available for out-of-round and thread grinding. In this case, the workpiece spindle is designed as a motor spindle with rotary positioning. This enables synchronized movements between the feed of the grinding spindle and the rotation of the workpiece.

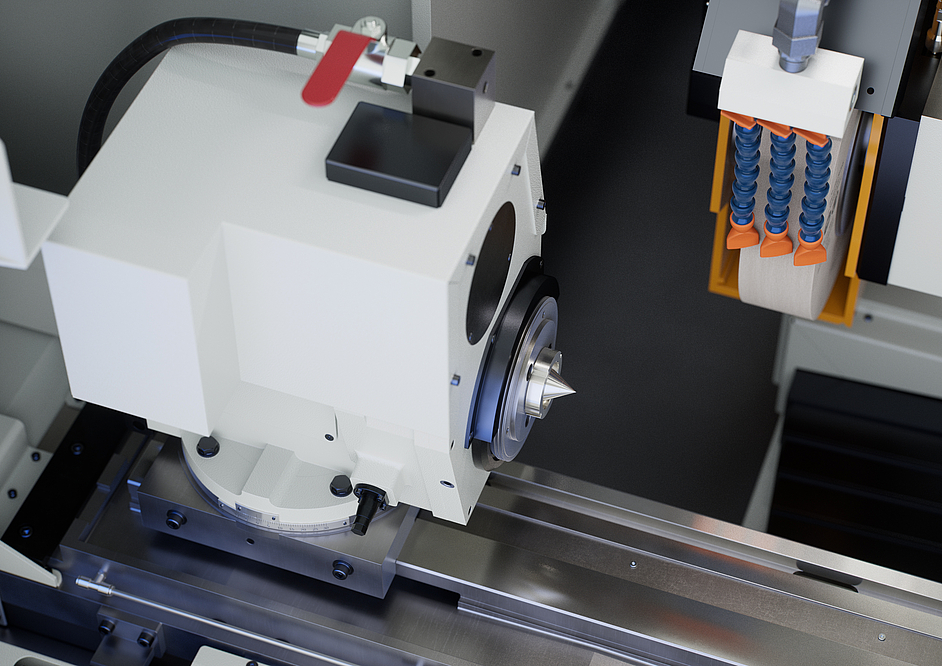

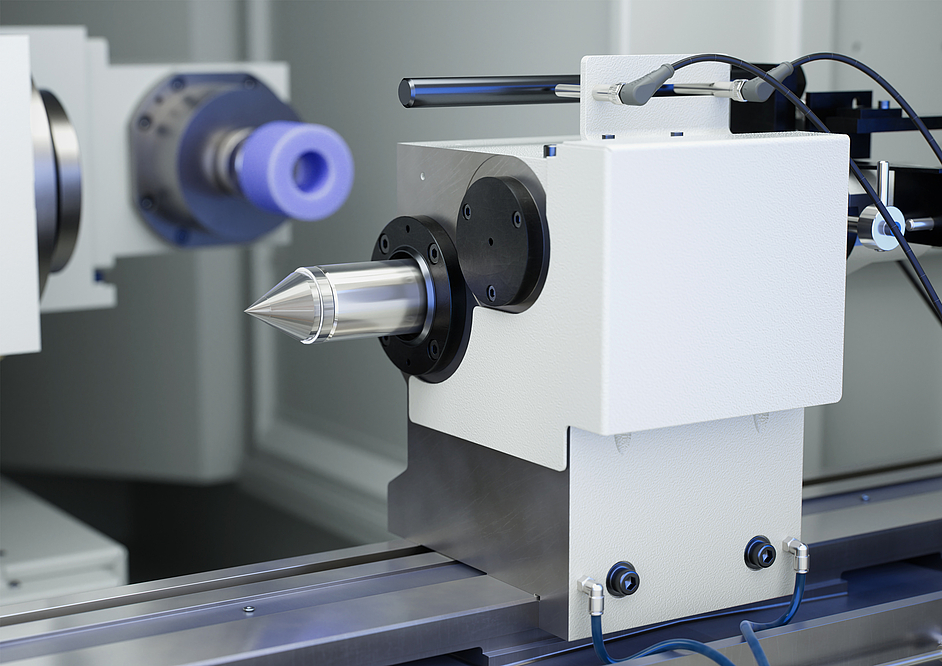

Tailstock - precision centering when grinding between centers

The standard tailstock is equipped with a quill with a diameter of 63 millimeters for MK4 centers. It runs low backlash in the guide, which enables precise centering of the workpiece. A fine adjustment of ±40 micrometers allow the correction of taper deviations and ensures concentricity of well under one micrometer.

Manual or hydraulic actuation systems are available. The hydraulic version speeds up workpiece changeover, as the quill is automatically retracted after machining. An integrated sensory equipment monitors the correct position of the workpiece tip and increases process reliability.

Dressing systems - ensuring constant grinding conditions

Various dressing systems are available for different requirements. Dressing is an essential part of the grinding process, as the geometry and sharpness of the grinding wheel significantly determine the surface quality and dimensional accuracy.

The following systems are available:

- Table dresser with flexible positioning: The table dresser can be placed at any position on the top table. This flexibility allows it to be adapted to different workpiece geometries and grinding wheel diameters. The user can optimize the dressing position for specific workpieces, which shortens set-up times for frequently changing production tasks.

- Dressing spindle on the workhead: The dressing spindle is mounted at the rear of the workhead and enables automated dressing without manual intervention. This solution is suitable for batch production where constant dressing cycles increase process reliability. Integration into the machine structure reduces the footprint and shortens non-productive times.

- Holder for dressing tiles on the tailstock and workhead: For simple dressing tasks, holders for dressing tiles can be mounted on the tailstock or workhead. This cost-effective solution is suitable for manual dressing processes or as a supplement to automated systems.

The modular design allows the dressing system to be adapted to the respective application. The selection of a suitable dressing system depends on the type of grinding wheel, number of pieces, workpiece geometry and required surface qualities.

Of course, the machines in the UG Series can be extended according to customer requirements, for example with NC synchronous tailstock, in-process measuring technology, automatic tailstock with NC axis, hydraulic steady rests and many other options.

Control and operation

The UG machines are equipped with the FANUC 0i-TF CNC control as standard. This control offers a dialog-oriented HMI that simplifies programming and operation. User guidance is logically structured, and frequently used functions are directly accessible.

The FANUC 31iB Plus is available for more complex contours, especially for out-of-round and thread grinding. This controller has a higher computing power and supports extended functions for synchronized motion control. Interpolation between the axes is performed with high precision, which is necessary for machining out-of-round geometries.

The use of FANUC controllers offers advantages in international applications. The controllers are used worldwide, service availability is high and spare parts are available at short notice. This minimizes downtime and facilitates the training of operators who are familiar with FANUC controls.

Worldwide customer support

EMAG maintains a global service network covering all continents. The service locations are in Germany, Great Britain, France, Spain, Italy, the USA, Mexico, Brazil, India, China and South Korea. This decentralized structure enables short response times and a rapid on-site presence for service requests.

The service technicians at all locations have access to a shared knowledge pool. Experiences from service cases are systematically analyzed and made available worldwide. This allows customers to benefit from the accumulated know-how of the EMAG organization irrespective of their location.

As an OEM supplier, EMAG guarantees to help the customer as quickly as possible - whether during commissioning, with technical questions or in the event of a malfunction. On request, EMAG can supply a turn-key package that includes not only the machine but also the tool, workholding technology, cutting fluids and the finished workpiece program. The customer thus receives a production-ready solution from a single source.

The service program also offers preventive servicing, training courses at the EMAG Academy, retrofits and original spare parts that are always available. The aim of all services is to maximize machine availability and ensure a long service life for the investment.

Contact

Oliver Hagenlocher

Area

Press and Communication