05/28/2025 - Oliver Hagenlocher - Customer Stories

Comprehensive machining expertise: EMAG VL lathes in the PENN GmbH production chain

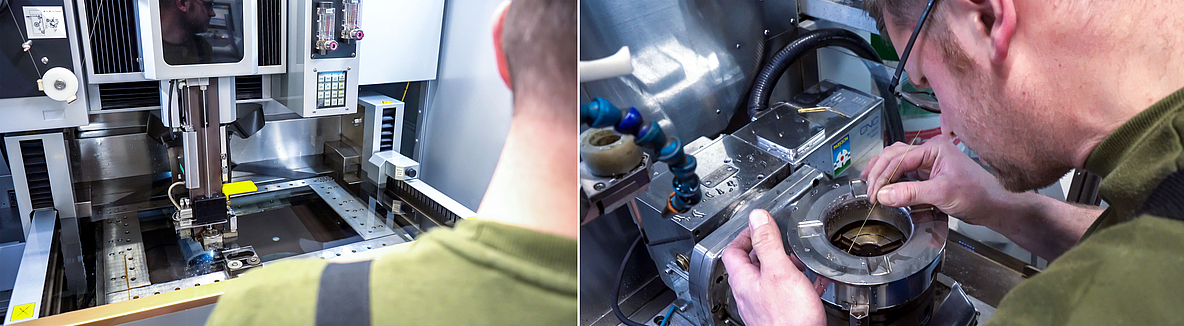

The increasing complexity of requirements in metal processing and international cost pressure pose particular challenges for manufacturing companies in high-wage countries. The Austrian company PENN GmbH has established itself as an internationally active metal processor through a high level of vertical integration and consistent automation. Vertical turning machines from EMAG's VL series, which have been in use at PENN for over a decade and have now grown to 43 spindles, play a key role in the production chain.

Images

From forged part production to complete-machining

Founded in 1965, PENN GmbH has developed from a small forging company into a high-tech supplier with over 700 employees. A milestone in the company's history was the investment in a Hatebur forging plant at the Stratzdorf site in 2007, which produces rotationally symmetrical forgings at a rate of up to 70 components per minute. This corresponds to an annual volume of up to 10 million forged parts.

The high production volume requires equally efficient machining technology. This is where the machines from EMAG come into play, as Managing Director Gernot Penn explains: "The majority of our forged parts are then machined in-house. We use our connected EMAG VL manufacturing systems for this, which run practically around the clock."

Customized machine concepts for large-scale production

The cooperation between PENN and EMAG began in 2010. The first systems - two connected VL 5i machines - were put into operation in 2011 and used for the machining of rotationally symmetrical forgings for the automotive industry. This was followed in 2014 by the first VL 2 machines for gear blanks, also for the automotive industry. The machine portfolio has been systematically expanded over the years and now includes over 30 EMAG VL 2 machines for machining small to medium-sized rotationally symmetrical workpieces, VL 2 DUO line machines with TrackMotion system for automated link-up, VL 3 DUO machines for larger workpieces and VL 5i systems for machining complex geometries.

Technical features of the EMAG VL series at PENN

The VL series from EMAG is characterized by its vertical design, which enables a particularly compact footprint. The vertical turning machines offer several technical advantages that are crucial for PENN's production requirements. First and foremost is the vertical pick-up spindle, where workpieces are picked up directly from the work spindle by integrated conveyor belts, eliminating the need for additional handling systems and minimizing non-productive time. The TrackMotion system allows several machines to be linked-up to form a flexible production line, ensuring an automated workpiece flow.

The powerful EMAG turret with turning and driven tools also enables complete-machining in a single setup of complex components. Last but not least, the machine body made of mineral casting and the vertical concept offer high thermal stability, which is particularly important in 20-shift operation.

Maximum machine availability - the decisive economic factor!

For a company like PENN, which has to hold its own against international competitors in the high-wage country of Austria, plant availability is a decisive economic factor. "We work in 20-shift operation for most of the year. With this production volume, machine availability and reliability are absolutely crucial," emphasizes Gernot Penn.

EMAG machines achieve an exceptionally high level of availability at PENN. This is made possible by several factors: The robust machine design with high rigidity forms the basis. In addition, there are preventive maintenance concepts that minimize downtimes, as well as fast service support from EMAG. Last but not least, the well-trained maintenance personnel at PENN also contribute to the high availability.

"As far as service is concerned: cheaper is always possible, there are cheaper machines everywhere. But it's the service that makes the decisive difference. You have to look at the machines in terms of life cycle costs," explains Penn. The close cooperation between the EMAG service team and the PENN maintenance technicians is a key success factor.

Automation as a competitive factor

In order to remain competitive despite the higher wage and non-wage labor costs in Austria, PENN also consistently relies on automation. "To be able to compete internationally, especially with low-wage countries, we need to implement smart automation solutions," explains Gernot Penn. "In Europe, there are countries with only 30 percent of the wage costs of Austria or Germany. We have to compensate for this difference with intelligent automation and high plant availability."

EMAG machines support this approach with their sophisticated automation concepts. The integrated workpiece feeding and removal significantly reduces manual effort. At the same time, the automated measuring technology ensures continuous process monitoring. The interlinking options provided by the TrackMotion system allow a continuous material flow without manual intervention.

These automation solutions enable PENN to use employees primarily for quality monitoring. "Above all, we expect our employees to have a high level of quality awareness. The actual work should be done by the machine. The employee must be able to concentrate on monitoring the quality produced."

Complete process chain under one roof

A particular advantage of PENN GmbH is its comprehensive vertical integration. From forging production and machining to assembly and final inspection, all process steps are carried out in-house. The EMAG machines are a central element in the value chain.

Future prospects and further development

PENN GmbH plans to merge all three Austrian sites at the Stratzdorf location by 2028, which will mean a significant rationalization boost. EMAG machines will play an important role in this, as their compact design enables high productivity per unit area.

In terms of market development, PENN is positioning itself broadly. "We are not focusing exclusively on the combustion engine or electromobility, but are keeping our eyes open in all directions," emphasizes Gernot Penn. This flexibility is also reflected in the versatility of EMAG machines, which can be used for a wide variety of workpieces and materials.

Economical production through optimized machine systems

The long-standing collaboration between PENN and EMAG demonstrates how modern machining technology can help to produce competitively even in high-wage countries. By combining high-performance forging systems, highly automated vertical lathes and comprehensive vertical integration, PENN has created a production system that combines maximum efficiency with maximum flexibility.

The 43 EMAG spindles in the VL series, some of which are in use around the clock, form the backbone of PENN's machining technology and underline the importance of reliable machine systems for economic success in metalworking.

Contact

Oliver Hagenlocher

Area

Press and Communication