10/01/2025 - Oliver Hagenlocher - Customer Stories

Compact angular plunge-cut grinding machine improves production processes

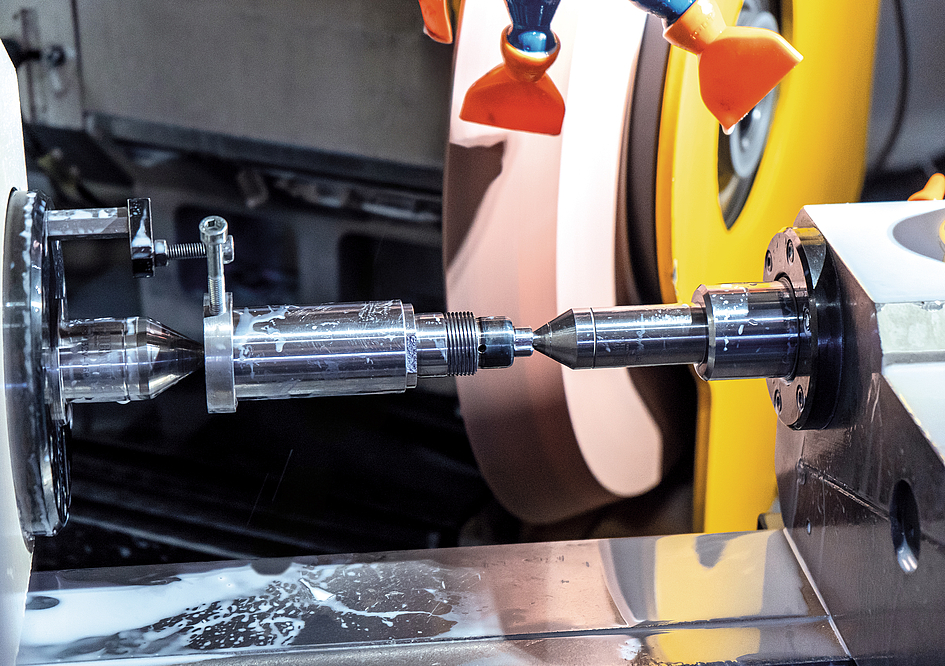

Over the past 50 years, Wandel CNC-Technik GmbH has developed into an established supplier with its own product portfolio. The Swabian family business, which is now managed by the second generation, has continuously expanded its production spectrum: from milling to turning and grinding. By investing in an EMAG WPG 7 angular plunge-cut grinding machine, the company has expanded its grinding capacities in a targeted manner.

Images

Diverse production spectrum requires flexible technologies

The company has 23 employees and produces between 15,000 and 20,000 components per month. The product range includes forged blanks, drive shafts and intermediate flanges for the commercial vehicle industry as well as classic machine components such as worm shafts. In the milling area, the focus is on gearbox housings made of aluminum, steel and cast iron. In grinding, the company concentrates on symmetrical or round components with diameters ranging from 10 to 150 mm and lengths of up to 1,000 mm.

Wandel CNC-Technik's own product portfolio includes ball screw nuts, which are manufactured in sizes between 16 and 50 mm. These are mainly used in handling technology, for adjusting platforms and in mechanical engineering.

Targeted investment in grinding technology

The WPG 7 is the fourth grinding machine to be added to the company's machine park. It was purchased specifically for the machining of flange nuts, for which angular plunge-cut grinding is a technological requirement. The machine is designed for batches of between 20 and 200 pieces and is retooled up to twice a day at high capacity.

The decision for a dedicated angular plunge-cut grinding machine was based on several factors: The company already had a straight plunge-cut grinding machine for long and larger components. The compact design of the WPG 7 enables short travel distances and fast movements - a significant advantage over larger universal machines. The limited space at the site also spoke in favor of the compact solution.

Technical advantages optimize the production process

One particular advantage of the WPG 7 is its thermal stability. The compact design significantly reduces heat transfer, which means that the machine works with precision immediately after being switched on. The angular grooving technology shows its strengths particularly in the machining of flanges that need to be ground for squareness or axial run-outs. Compared to previous machining methods, shorter running times and higher qualities are achieved. The modern control system of the WPG 7 enables user-friendly programming directly at the machine, whereby the programs for around 50 different components can be saved and called up again as required.

Increased efficiency through adapted technology

The investment in the WPG 7 has paid off for Wandel CNC-Technik in several respects: the compact design ensures optimum use of space and the thermal stability guarantees consistently high quality, while the angular plunge-cut technology enables better machining results for flange parts. The short travel distances and ease to operate contribute to increased efficiency, while the quick installation and good support from EMAG enabled a smooth transition to production.

Contact

Oliver Hagenlocher

Area

Press and Communication