EMAG at the EMO 2025

Visit us from September 22 to 26, 2025 at booth B22 in hall 17 at the EMO in Hanover!

We will be presenting our latest machines, technologies, automation solutions and manufacturing systems:

- MSC 5 DUO:

Two-spindle CNC lathe for high-productivity flange machining - Turning center incl. counter spindle VTC 200 with robot cell MRC:

Fully automatic complete-machining of differential housings - VL 4:

Precision hard turning with PICEA clamping system - VTC 100 GT:

Hard turning and grinding of rotor shafts - HLC 150 H:

Power skiving and hobbing of stepped planetary gears for electric drives

- WPG 7:

High-precision external cylindrical grinding with minimal footprint incl. automation - GP 500 H:

Grinding of double helical gears for aerospace applications - ELC 6i:

Laser welding for powertrain components - ECM Boost Technology:

Manufacturing high-tech components in the shortest possible time - without the negative influences that occur with EDM - Solutions for the defense industry:

ECM Rifling - precision barrel machining & manufacturing systems for artillery ammunition

Order free admission tickets to EMO

Here you can order free admission tickets to EMO. You can register for tickets on the trade fair website.

Visit us at booth B22 in hall 17 - our team is looking forward to presenting our designs and developments to you!

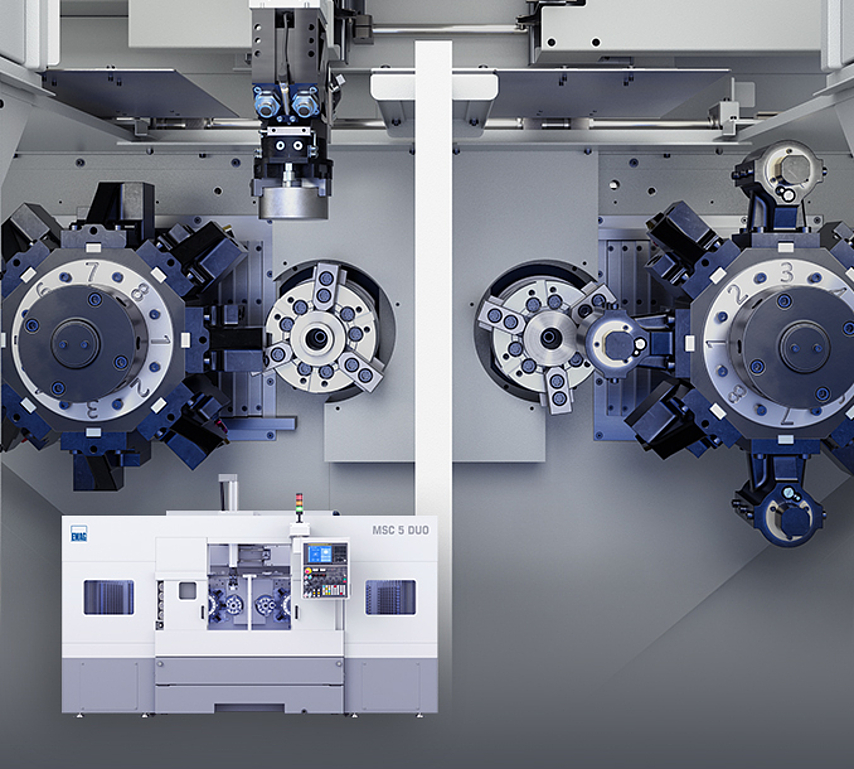

MSC 5 DUO - two-spindle CNC lathe for high-productivity flange machining

The MSC 5 DUO is a high-productivity, front-loaded, twin-spindle CNC lathe that is ideal for the automated machining of flanges and chucked components. The innovative split-bed design mechanically decouples both work areas, enabling maximum precision with simultaneous machining. With two main spindles, an 8-station BMT turret and an integrated 3-axis gantry loader , the lathe achieves extremely short cycle times and delivers maximum accuracy with a minimal footprint. It is perfect for medium to large batch production.

VL 4 - precision hard turning with PICEA clamping system

The VL 4 shows its strengths in the precision hard machining of thin-walled components, such as ring gears, and is supported by the intelligent PICEA clamping system from Sterman. Thanks to the integrated piezo actuators, the workpiece is precisely centered and can be aligned in a targeted manner to compensate for out-of-roundness and achieve perfect coaxiality. The system's sensory equipment records clamping paths and geometries in real time, enabling adaptive, deformation-free clamping. This technology opens up new possibilities for manufacturing sophisticated components such as ring gears or sun gears with process reliability and precision.

VTC 200 turning center incl. counter spindle with MRC robot cell for fully automatic complete-machining of differential housings

Another highlight in the field of automation is the VTC 200 vertical turning center with counter spindle in combination with the MRC modular robot cell. This system enables the fully automated complete-machining of differential housings: both sides of the component are machined with precision, with the component being transferred directly from the first to the second clamping operation, significantly reducing lead times and handling effort.

Our MRC cell handles automated machine loading with ease. In addition to workpiece handling and pallet logistics, it integrates secondary processes such as post-process measurement in this case. Its modular design allows the range of functions to be flexibly expanded - for example, to include bin picking or loading by an AGV. This makes the MRC an adaptable and versatilesolution for automated production.

VTC 100 GT - Hard turning and grinding of rotor shafts

The VTC 100 GT from EMAG enables the complete-machining in a single setup of rotor shafts by combining hard turning, Scroll free turning and grinding. Bearing and sealing ring seats are precision pre-turned and ground to achieve the required IT6 tolerances and surface finishes of Rz 1-3 µm without twisting. The vertical design ensures optimum chip fall and high process reliability. Integrated measuring and automation systems ensure consistent quality with maximum productivity and minimal footprint.

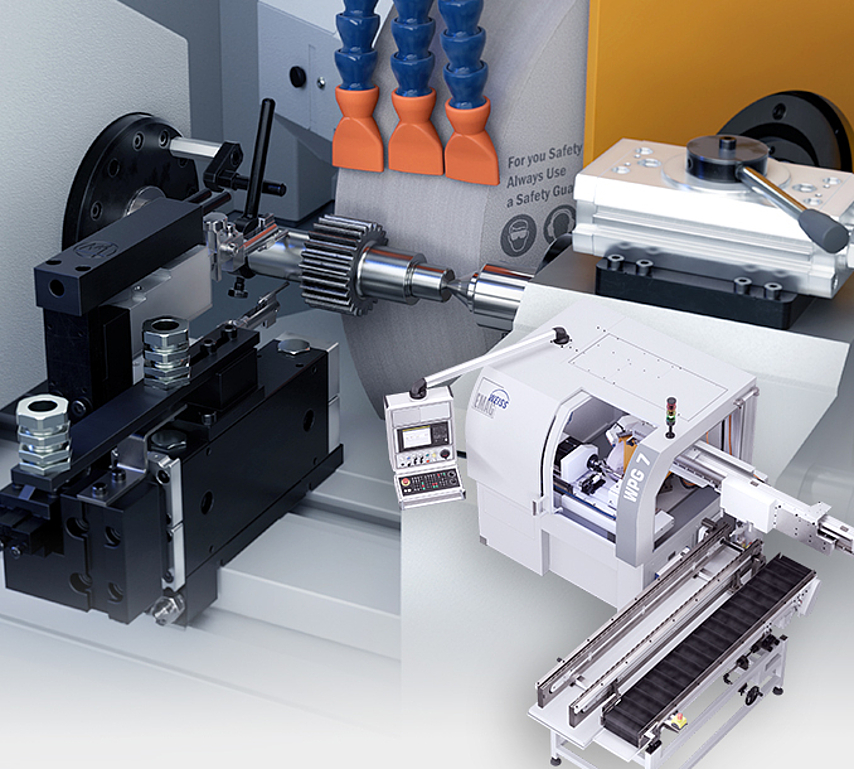

WPG 7 - high-precision external cylindrical grinding with minimal footprint incl. automation

The WPG 7 offers high-precision external cylindrical grinding with a minimum footprint - and maximum automation. With an integrated linear gantry and double gripper, the machine loads and unloads the workpieces independently and reliably leading to short chip-to-chip times. It is perfect for short shafts up to 250 mm in length as well as for chucked components and is ideal for flexible batch production with the shortest cycle times.

GP 500 H - Grinding of double helical gears for aerospace applications

EMAG presents the GP 500 H at the EMO. This profile grinding machine enables the precision grinding of double helical gears , such as those used in turbofan engines and helicopter gearboxes . Thanks to its 5-axis kinematics, counter bearing system and integrated measuring technology, it meets the highest requirements for precision and process reliability.

HLC 150 H - Power skiving and hobbing of stepped planetary gears for electric drives

The HLC 150 H machines complex geometries using an intelligent combination of processes: The smaller tooth profiles are machined by power skiving to avoid collisions with the adjacent shoulder. While the larger helical gearing is efficiently produced using the hobbing process with a higher metal removal rate. The swiveling machining head enables seamless switching between the two processes without the need for reclamping. This technology ensures maximum precision in the orientation of both tooth profiles in relation to each other. This is a decisive factor for the functionality of modern planetary gears in electromobility.

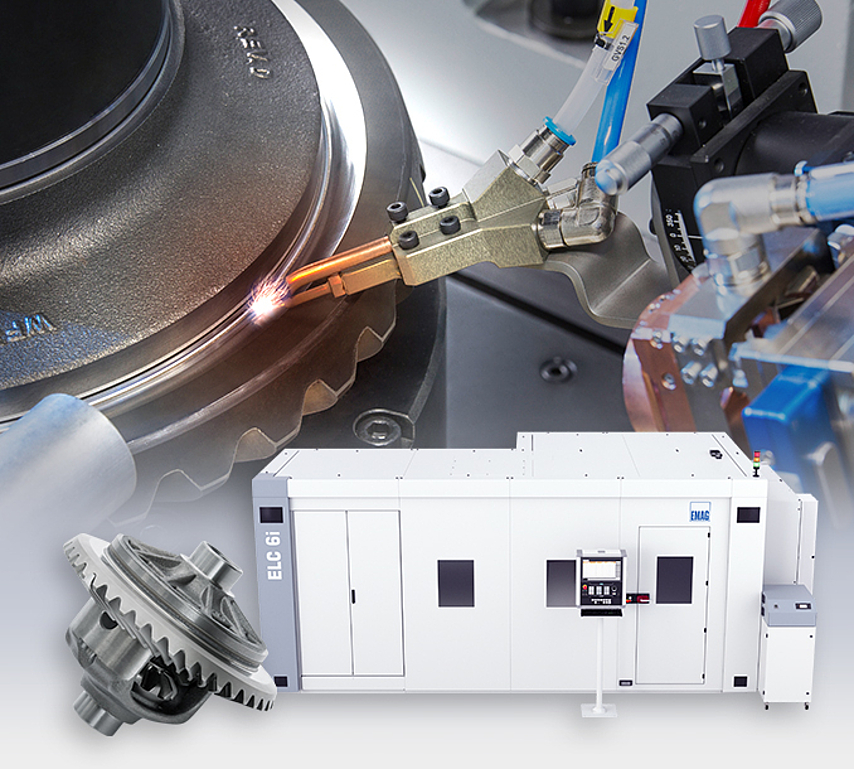

ELC 6i - Laser welding for powertrain components

The ELC 6i is a compact machine for powertrain components that combines the processes of cleaning, preheating, joining, welding and marking. The standardized "all-in-one" concept enables economical production of large quantities, reduces engineering costs and shortens delivery times. The ELC 6i guarantees short cycle times with an integrated transfer system and precision multi-axis technology, achieving the highest welding quality and minimal component distortion. This is crucial for the efficient production of e.g. differentials, intermediate shafts or rotor shafts in modern powertrain lines.

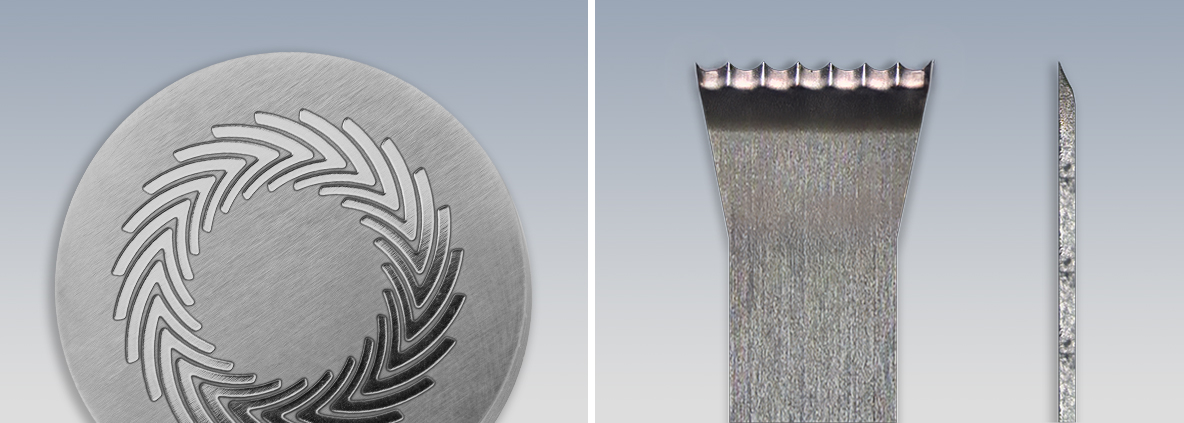

ECM Boost Technology: Manufacturing high-tech components in record time - without the drawbacks of conventional manufacturing processes

The new, patented "ECM Boost" generator technology from EMAG enables high-precision machining of complex contours with reduced cycle times. The ideal pulse shape achieves a uniform current density, increases the removal rate and minimizes the stray field effect. Meaning even filigree structures, such as the inner contour of air bearings or the micro-sharp cutting edges of medical scraper tools, can be produced with precision without thermal side effects and edge field interference.

ECM Boost offers decisive advantages compared to conventional manufacturing processes: Without heat-affected zones, edge field influence and tool wear, it is possible to machine several components individually or simultaneously with high precision. The technology opens up the feasibility of geometry details and accuracies that were previously impossible to achieve and significantly expands the possible applications of ECM - from the automotive sector to aviation and medical technology.

Solutions for the defense industry: ECM Rifling - precision barrel machining & manufacturing systems for artillery ammunition

The innovative ECM Rifling process enables electrochemical barrel machining without mechanical stresses - for polygonal, progressive and standard rifling with maximum precision. Special rifling modules in modular PI machines enable simultaneous barrel machining scalable from two to eight times.

In addition, EMAG offers customized manufacturing systems for artillery ammunition with automated processes that ensure maximum accuracy and the highest productivity level.

Order free admission tickets to EMO

Here you can order free admission tickets to EMO. You can register for tickets on the trade fair website.

Brochures and Press Releases

Download the exhibit brochures here:

EMAG Group Product Overview

MSC 5 DUO - Two-spindle CNC lathe

VT Series - Vertical pick-up turning machines for shafts

VL Series - Vertical pick-up turning machines

VTC 100 GT - Hard turning and grinding machines

HLC 150 H - Gear hobbing machine

WPG 7 - External cylindrical grinding machine

ELC 6/ELC 6i

EMAG SU Product Overview

ECM Product Overview

Manufacturing solutions for the defense industry

Download press releases on the EMO highlights here: