Archivio

09/09/2024 - Oliver Hagenlocher - Stampa

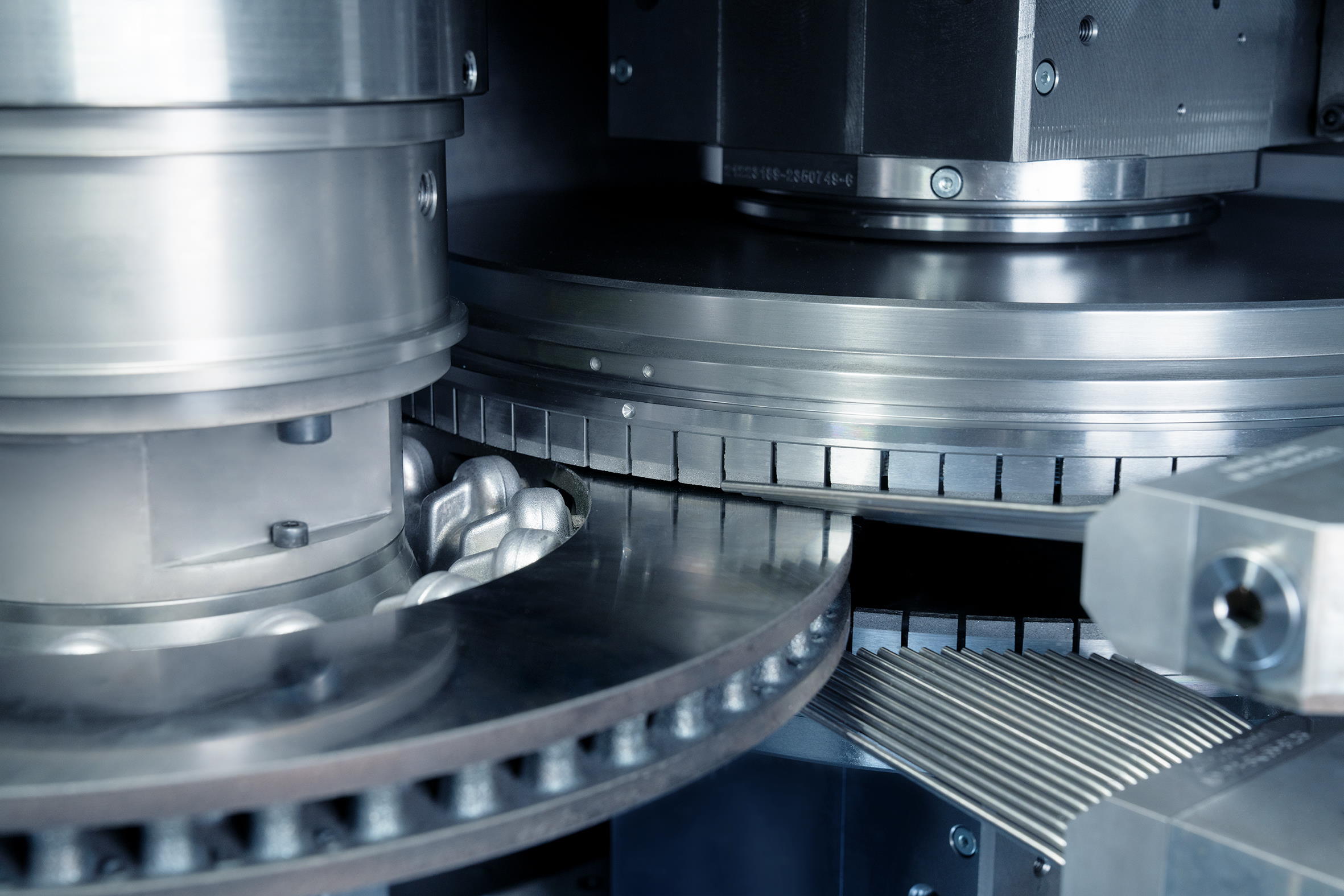

The new VST 50 from EMAG: A new ball pin leaves the machine every seven secondsWhether in the steering system or in the chassis - ball joints are indispensable in our cars. They not only act as a kind of pivot point between different elements, but are also usually in constant motion and exposed to high physical loads. In this…

03/05/2024 - Oliver Hagenlocher - Stampa

New opening of the EMAG plant in Querétaro, MexicoThe EMAG Group opened its new plant in the San Isidro Business Park in Querétaro, Mexico, on April 25, 2024. This step is another milestone in the company's 20-year success story in the Mexican market and underscores EMAG's commitment to the region.

25/04/2024 - Oliver Hagenlocher - Stampa

EMAG at the GrindingHub 2024 – Grinding technology for the low-emission mobility of the futureGrinding is a key technology for the resource-saving and low-emission mobility of the future. Examples of this include electric drives, which place the highest demands on the precision and surface properties of transmissions and engine components, or…

13/03/2024 - Oliver Hagenlocher - Stampa

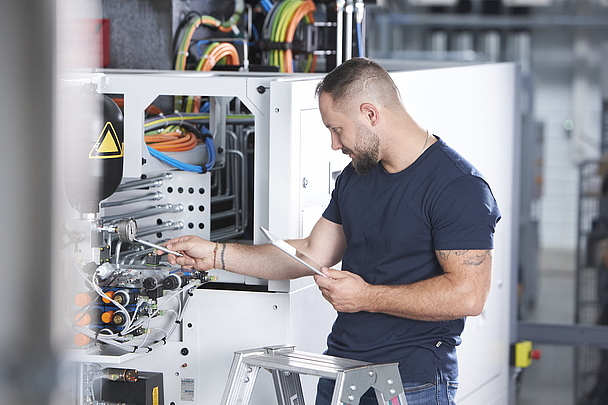

EMAG is working on "green manufacturing": Pulling out all the stops for greater energy efficiencyHow important is the topic of "climate-neutral production" for industry at this moment? A recent survey conducted by the German Engineering Federation (VDMA) among its member companies provided an impressive answer. According to the survey, more than…

02/02/2024 - Oliver Hagenlocher - Stampa

EMAG Middle East Announces Opening of Office with International Free Zone in DubaiThe EMAG Group has officially opened its new sales company EMAG Middle East with the International Free Zone Authority (IFZA) in Dubai. With this expansion, the company is taking an important step into the fast-growing markets of Central Asia and the…

09/01/2024 - Oliver Hagenlocher - Stampa

Soluzioni di rettifica di EMAG SU: Finitura superficiale estrema per la mobilità elettricaParticolare precisione e affidabilità dei processi hanno caratterizzato l'ingegneria automobilistica per molti decenni. Con l'affermarsi della mobilità elettrica, tuttavia, queste esigenze stanno aumentando ancora una volta, perché molti componenti…

18/12/2023 - Oliver Hagenlocher - Stampa

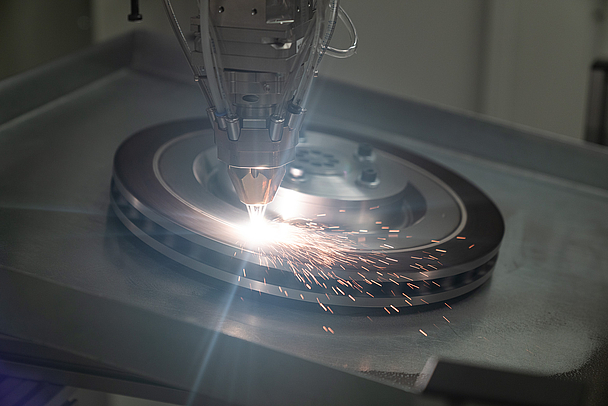

FATECO project: Together for a greener and safer futureThe EU's FATECO project embodies a collaborative partnership to improve road safety trough eco-sustainable mechanical processes. Launched in 2018, the FATECO project brings together a consortium of experts who are working together to reduce the…

01/12/2023 - Oliver Hagenlocher - Stampa

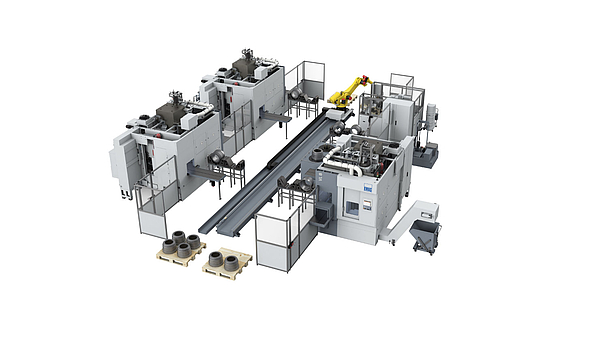

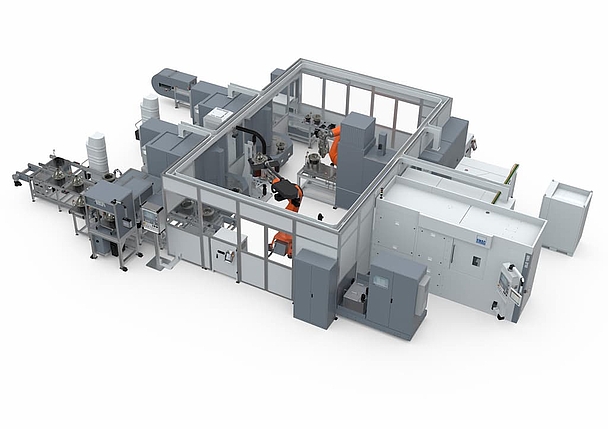

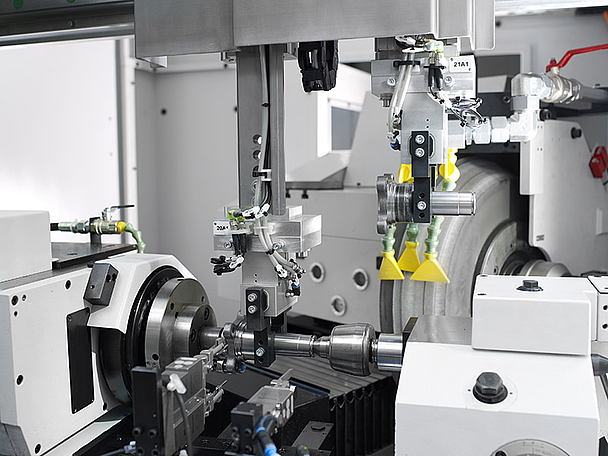

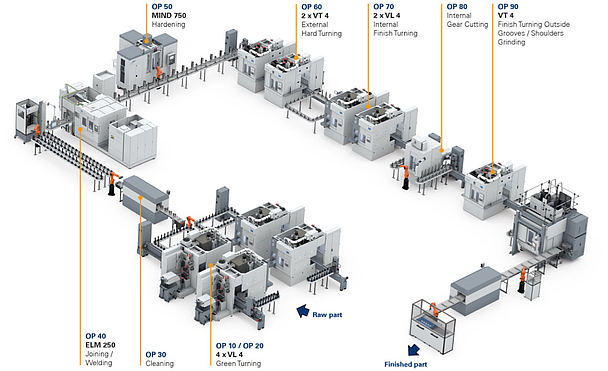

EMAG sviluppa soluzioni di produzione integrate: Applicazioni robotizzate di precisione assicurano un flusso rapido di componenti durante la produzioneL’ausilio di sistemi di automazione robotizzati per asservire le linee di produzione viene oggi sempre maggiormente impiegato, soprattutto per velocizzare il processo di lavorazione e ridurre i costi pezzo unitari. EMAG è un esempio di come un…

19/10/2023 - Oliver Hagenlocher - Stampa

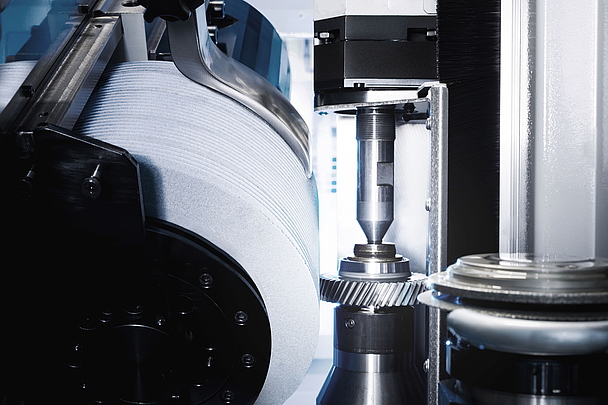

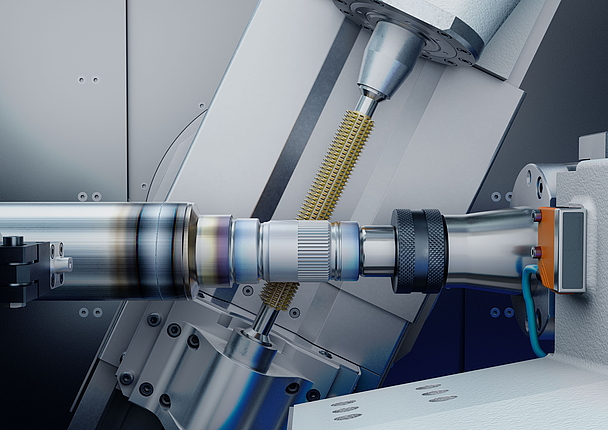

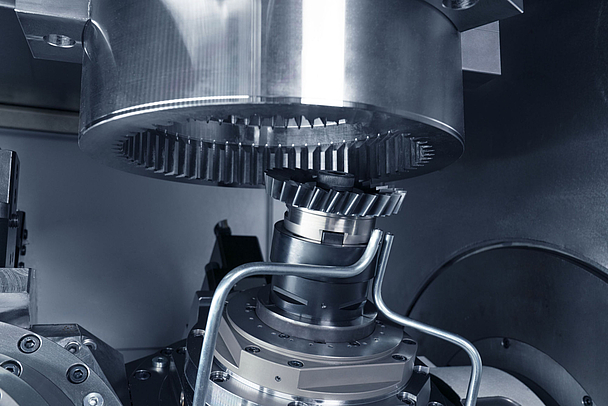

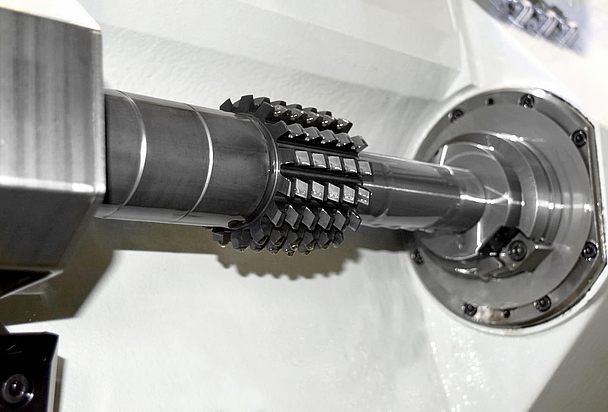

La dentatrice a creatore HLC 150 H di EMAG Koepfer: L'albero del rotore delle e-car si incastra con alta precisione in un ciclo rapidoL'editing dei denti di un albero rotore per auto elettriche è un'attività di elaborazione impegnativa: In nessun altro campo di applicazione i componenti della trasmissione sono sottoposti a requisiti così elevati. Sono richieste le più alte finiture…

22/09/2023 - Oliver Hagenlocher - Stampa

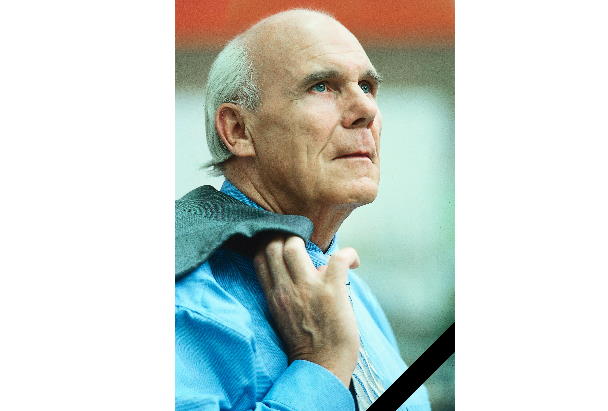

The EMAG Group mourns the loss of its former CEO: The visionary entrepreneur Norbert Heßbrüggen has diedNorbert Heßbrüggen is dead. The former CEO and shareholder of EMAG passed away on September 17, 2023, at the age of 88 in his hometown of Salach. The company owes a lot to him: Under his leadership from the end of the 1960s, the small southern German…

31/08/2023 - Oliver Hagenlocher - Stampa

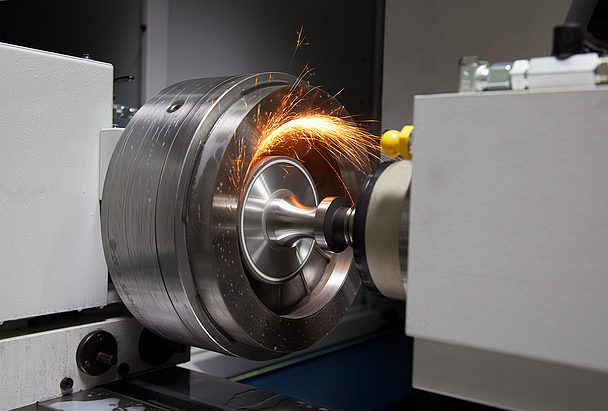

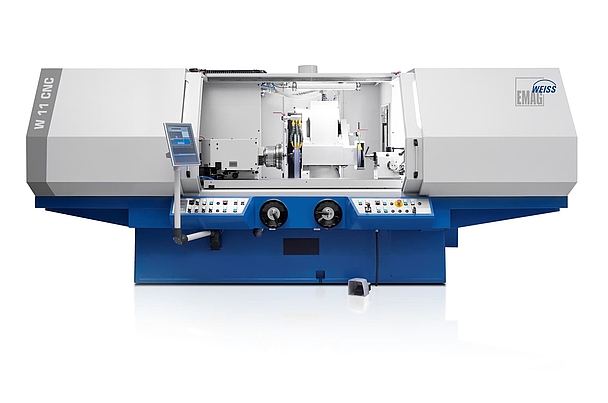

W 11 Rettificatrice cilindrica CNC di EMAG Weiss: Esecuzione di operazioni di rettifica in rapida successioneEstrema precisione e massima efficienza: questi sono i requisiti richiesti dalla rettifica cilindrica per esterni in diversi settori: dalla la tecnologia medica, all'ingegneria meccanica generale. Ma anche per la produzione di piccole serie o di…

16/08/2023 - Oliver Hagenlocher - Stampa

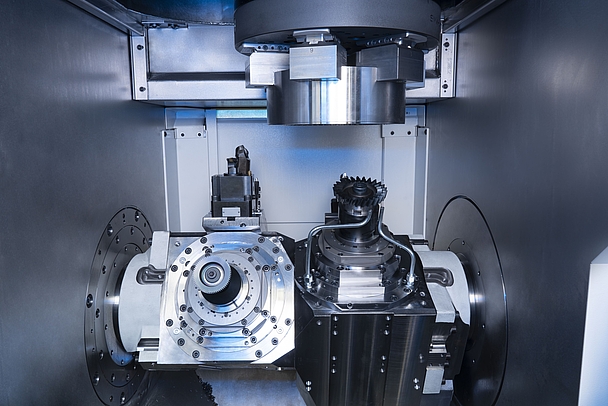

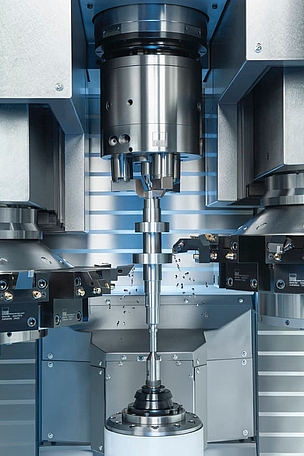

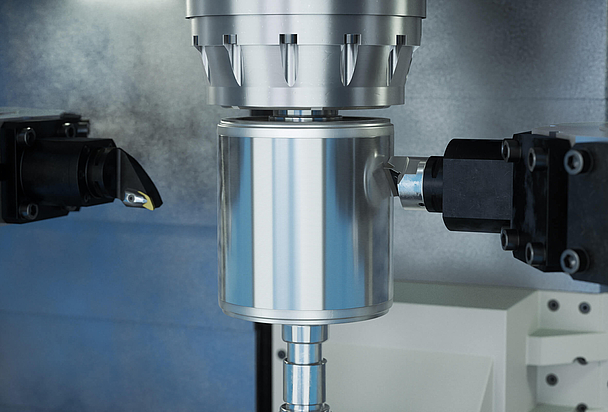

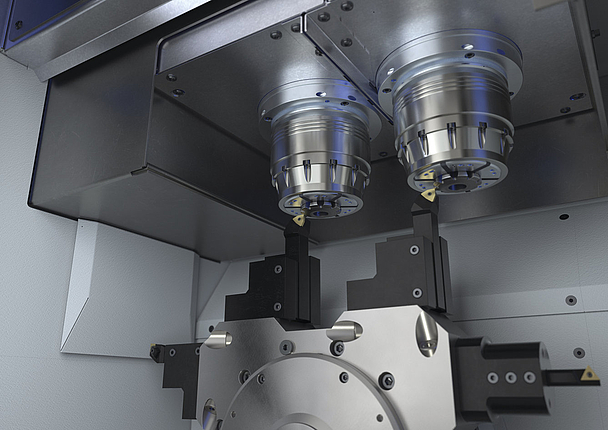

VSC 400 PS: lavorazione combinata precisa ed efficienteTra i prodotti in esposizione allo stand di EMAG nella prossima edizione della fiera EMO di Hannover, sarà presente anche la VSC 400 PS, uno degli ultimi sviluppi del Gruppo, che unisce in un’unica macchina i processi di tornitura e dentatura,…

01/08/2023 - Oliver Hagenlocher - Stampa

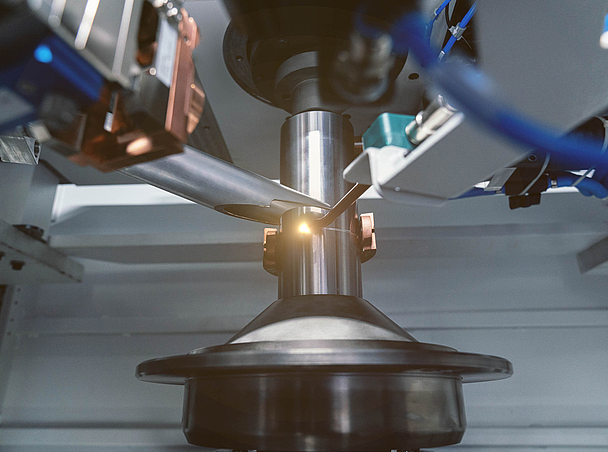

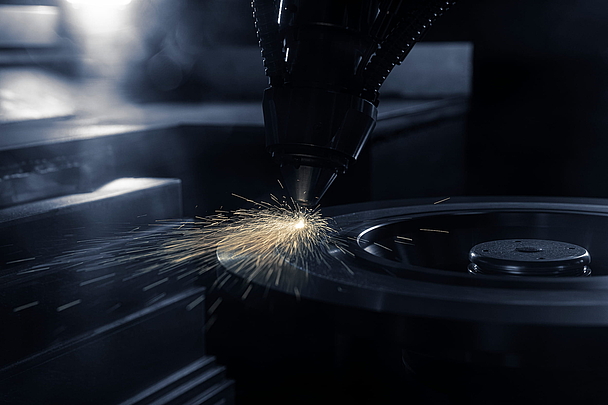

ELC 6 di EMAG LaserTec: Perfezionamento del processo di saldatura dell’albero rotoreLe vendite di auto elettriche sono in aumento in tutto il mondo e ad un ritmo elevato. L'Agenzia Internazionale dell'Energia (AIE) stima che quest'anno saranno venduti 14 milioni di veicoli elettrici, il che corrisponde a un aumento delle vendite del…

04/07/2023 - Oliver Hagenlocher - Stampa

EMAG Group receives major order from KamLitKZSeveral important economic agreements were signed during the German-Kazakh Economic Forum, which took place in the Kazakh capital Astana on June 20, 2023. The economic forum was attended by prominent politicians, including Kazakh President…

29/06/2023 - Oliver Hagenlocher - Stampa

EMAG starts construction of a new plant in MexicoOn June 19, 2023, the symbolic groundbreaking ceremony took place for the new plant of the EMAG Group in the San Isidro Business Park in Querétaro, Mexico. This marks the start of an ambitious investment program of the EMAG Group in the region.

17/05/2023 - Oliver Hagenlocher - Stampa

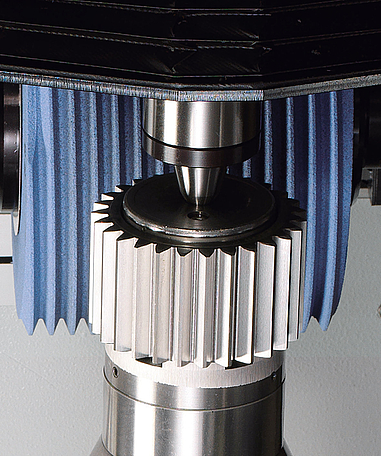

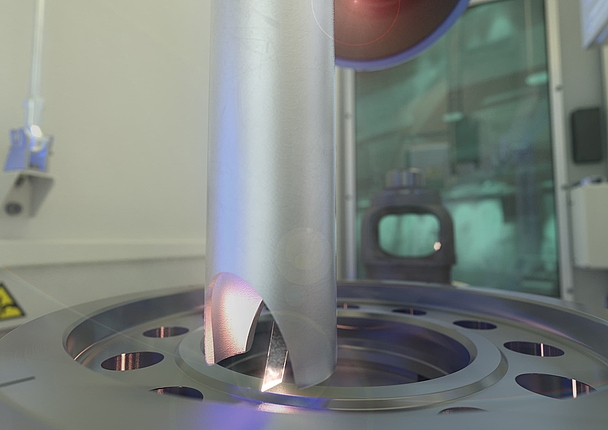

Rettifica dei fianchi dei denti con EMAG SU: Superfici microscopicamente perfette e tempi ciclo minimi per la mobilità elettricaNella produzione di componenti per gli azionamenti elettrici, la rettifica è sempre più al centro dell'attenzione: i responsabili della produzione richiedono nuove soluzioni per una superficie perfetta che garantisca la necessaria silenziosità con…

03/04/2023 - Oliver Hagenlocher - Stampa

Markus Clement becomes new CEO of EMAG GmbH & Co. KGDr. Heinz-Jürgen Prokop will hand over the CEO position to Markus Clement on April 1, 2023. "My mandate was to lead EMAG until a long-term and forward-looking appointment is found for this responsible position. Markus Clement and I made contact very…

15/02/2023 - Oliver Hagenlocher - Stampa

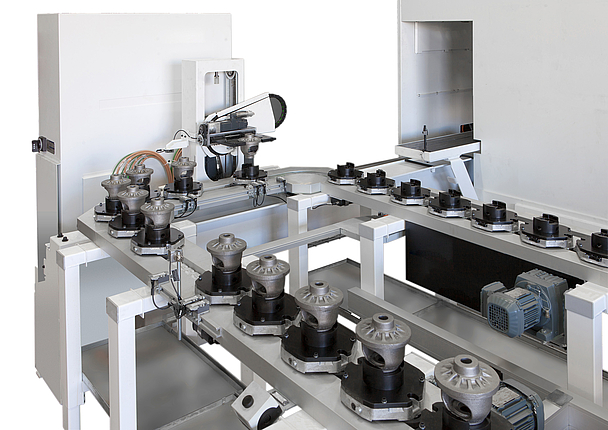

TrackMotion, Robot e Co.:Come i fornitori e i produttori per conto terzi traggono vantaggio dalle soluzioni di automazione snella

Le ragioni per l'utilizzo dell'automazione e della robotica nell'industria manifatturiera sono molteplici e vanno dalla compensazione della…

16/01/2023 - Oliver Hagenlocher - Stampa

The EMAG Group and HPL Technologies conclude extensive Cooperation AgreementEMAG and HPL Technologies agree on an extensive cooperation in the field of hard coating of brake discs. Hard-coated brake discs are the preferred solution for compliance with the "EURO 7" fine particulate matter limits.

07/11/2022 - Oliver Hagenlocher - Stampa

Efficienza garantita con VSC 400 PS: Power skiving e tornitura combinate per soluzioni di dentatura complessePer molti clienti che producono dentature il power skiving risulta un'opzione sempre più interessante. Non c'è da stupirsi, dato che questo processo è molto più rapido della stozzatura e più flessibile della dentatura a creatore e la brocciatura.…

26/09/2022 - Oliver Hagenlocher - Stampa

New management trio at EMAG making plans for the futureA new company management trio combined with a whole range of new products and innovations – EMAG is moving into the next few months with real momentum, and can look back on a successful first half of the year with a very strong order intake. There…

30/08/2022 - Oliver Hagenlocher - Stampa

EMAG at the AMB 2022 in Stuttgart: Making industrial production more flexible, more productive, and more sustainableMaximum productivity and sustainability, with flexible machine solutions for many different production tasks and sectors – this best summarizes the EMAG Group’s focus for this year’s presence at the AMB from September 13 to 17 in Stuttgart. At the…

26/07/2022 - Oliver Hagenlocher - Stampa

Inspection and Maintenance by EMAG: Reduce unnecessarily costly machine downtimes through targeted measuresThe greatest benefit of regular maintenance in industrial production is obvious – unscheduled machine downtimes are systematically avoided, which has a huge economic benefit for users. Take, for example, a turret. Investing a little money in having…

20/06/2022 - Oliver Hagenlocher - Stampa

Applicazioni laser per l'elettromobilitàSono molte le sfide nel settore dell'elettromobilità o, per essere più precisi, nella produzione industriale dell'e-mobility. Precisione, pesi ottimizzati, nuovi standard ambientali e così via: i requisiti per gli organi di trasmissione del moto sono…

21/04/2022 - Oliver Hagenlocher - Stampa

EMAG at the Grinding Hub 2022Grinding solutions for components from electromobility, data-optimized production and much more

20/01/2022 - Oliver Hagenlocher - Stampa

Pulizia al laser di EMAG LaserTec: processi di pulizia efficienti in spazi minimiPrima di essere destinati al processo produttivo successivo, molti pezzi devono essere “puliti”. La scelta del processo di pulizia riveste un ruolo decisivo: il processo deve essere configurato in maniera precisa per utilizzare sempre la quantità…

03/01/2022 - Oliver Hagenlocher - Stampa

EMAG sells EMAG eldec GmbH as part of a management buy-out (MBO)EMAG eldec GmbH becomes eldec Induction GmbH. All jobs will be retained. The previous managing director Thomas Rank takes over the shares of eldec GmbH from the EMAG Group.

14/12/2021 - Oliver Hagenlocher - Stampa

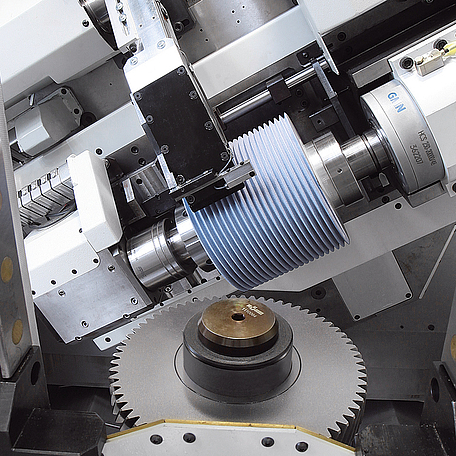

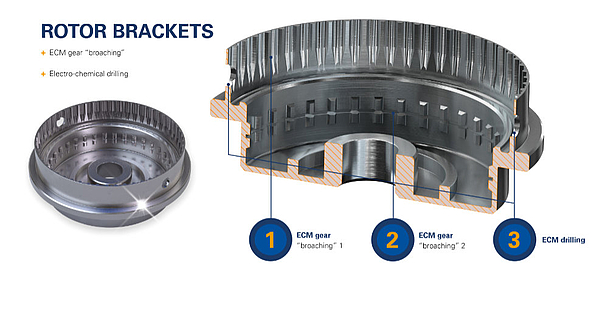

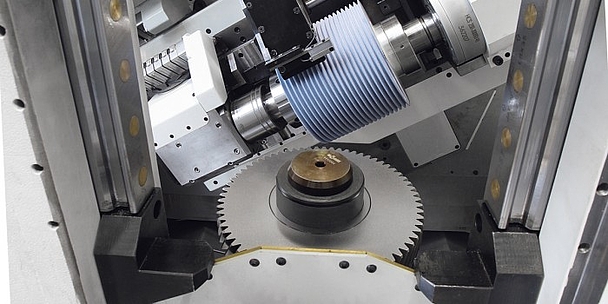

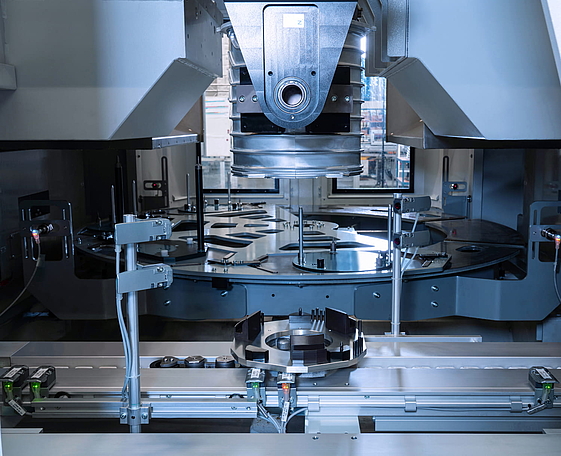

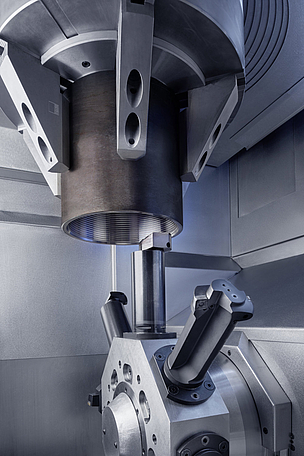

Lavorazione elettrochimica dei metalli di EMAG ECM: corrente invece di punta e fresa, la tecnologia ECM come alternativa all'asportazione di trucioloLa lavorazione elettrochimica dei metalli (ECM) è una tecnologia collaudata per la rimozione di bavature, tuttavia le sue potenzialità sono molto maggiori. L'azienda EMAG ECM intende sostituire foratura, brocciatura e fresatura con questo processo…

04/11/2021 - Oliver Hagenlocher - Stampa

EMAG SU: High-tech solutions for top component quality when cutting gear teethSectors ranging from the automotive industry, aerospace technology, transmission engineering, and numerous others are going through a technological transformation, with many users requiring increasingly powerful production solutions to reduce their…

25/10/2021 - Oliver Hagenlocher - Stampa

Vertical Turning Center from EMAG Scherer: Machining Large Quantities of Stator Housings with Speed and PrecisionElectric cars still account for a relatively small proportion of total car sales, and a trend toward rapid growth for electric car production is still a long way off. But there are exceptions, as demonstrated using EMAG Scherer’s technology at a…

04/10/2021 - Oliver Hagenlocher - Stampa

Rettificatrici in tondo universali EMAG Weiss - Una soluzione adatta praticamente per tutti gli utilizzatori.Le rettificatrici in tondo universali EMAG Weiss aprono nuove strade per il gruppo EMAG. L’azienda con sede a Salach, vicino Stoccarda (Germania), è nota soprattutto per le macchine (di rettifica) per la produzione di grandi serie. Le macchine…

29/09/2021 - Oliver Hagenlocher - Stampa

Workshop and data analysis package: EMAG partner anacision speeding up the pace of Industry 4.0 implementationIndustry 4.0 is very much on the rise in Germany. According to a survey carried out last year by digital association Bitkom, roughly six in ten German companies are already relying on applications from this field. However, just 14% of them are using…

13/09/2021 - Oliver Hagenlocher - Stampa

EMO 2021 a Milano: EMAG mette in esposizione soluzioni di produzione altamente flessibili, dedicate alla mobilità elettrica.Elevata flessibilità e allo stesso tempo processi di rettifica e tornitura appositamente sviluppati per il settore della mobilità elettrica, questi sono gli obiettivi di EMAG. La prossima fiera EMO, che si terrà a Milano dal 4 al 9 ottobre…

06/09/2021 - Oliver Hagenlocher - Stampa

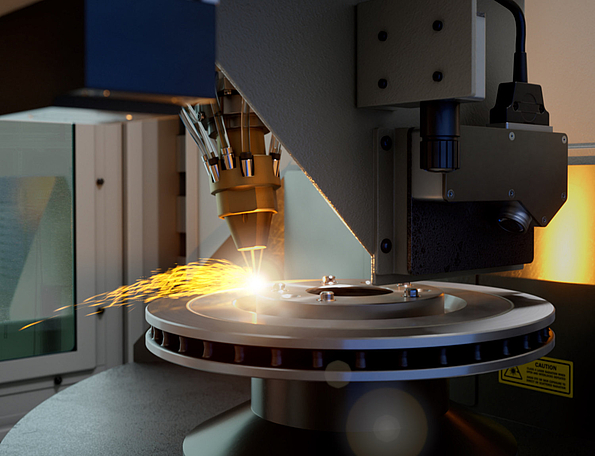

Laser Metal Deposition: EMAG develops production solution for coated brake disksThe car brake disk of the future is wear-resistant – and lasts as long as the car. This is made possible by a two-layer carbide coating that is applied to the disk using laser welding. EMAG LaserTec is currently engineering the associated integrated…

22/07/2021 - Oliver Hagenlocher - Stampa

Analisi dei dati più frequenti per il rilevamento delle anomalie: un processo di recente sviluppo per la valutazione durante il processo di lavorazione:“rilevamento anomalie in process”Le condizioni di produzione di molte aziende fornitrici cambiano continuamente: da una parte i componenti automotive diventano sempre più complessi, dall’altra aumentano in modo estremamente rapido i requisiti dei produttori OEM relativamente a…

02/06/2021 - Oliver Hagenlocher - Stampa

Soluzione produttiva per autocarri: EMAG offre una soluzione di produzione compatta per i mozzi delle ruote per autocarriL’e-mobility sta prendendo sempre più piede non solo nel settore delle automobili ma anche, da tempo, nel settore degli autocarri, dando il via a una competizione per guadagnarsi le fette di mercato future. Oltre ai produttori rinomati, nuovi marchi…

10/05/2021 - Oliver Hagenlocher - Stampa

Soluzione produttiva per autocarri: EMAG mostra una soluzione produttiva compatta per i grandi tamburi freno di veicoli commercialiGli autocarri sono i mezzi più utilizzati per il trasporto merci. In Germania oltre il 71% delle merci vengono trasportate su autocarri, mentre negli Stati Uniti la percentuale arriva sino al 72,5%. Solo nel 2019 sulle strade tedesche sono stati…

16/03/2021 - Oliver Hagenlocher - Stampa

Tornio verticale per alberi: Lavorazione a 4 assi di alberi del rotore, alberi di trasmissione ed altri componentiNella produzione di alberi, il tornio verticale per alberi VTC 200 garantisce numeri record per le grandi serie.

16/02/2021 - Oliver Hagenlocher - Stampa

Acquisizione da parte del gruppo EMAG: La Samputensili diventa EMAG SUIl 3 febbraio 2021 la Samputensili Machine Tools e la Samputensili CLC – compresi i 78 dipendenti nei due stabilimenti vicino Bologna e Reggio Emilia – sono state acquisite dal gruppo EMAG. In questo modo il costruttore tedesco dà vita a una nuova…

04/11/2020 - Oliver Hagenlocher - Stampa

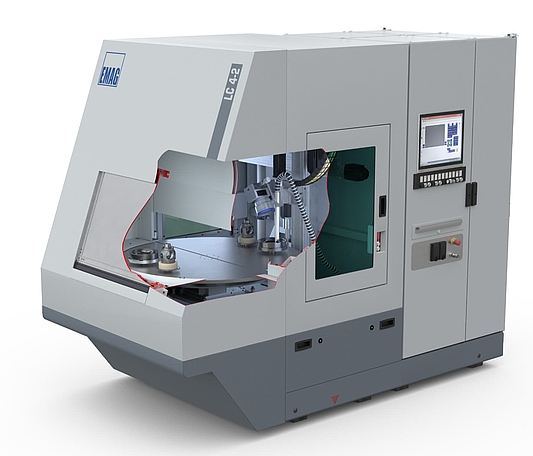

Macchina per pulizia laser LC 4-2: rapidi processi di pulizia e ottimizzazione delle superfici dei componentiLa pulizia industriale è una procedura piuttosto comune: molti componenti presentano infatti impurità, come olio e colla, o sono rivestiti da strati di ossido, ruggine, fosfato o vernice, che devono essere rimossi prima della lavorazione successiva.…

05/10/2020 - Oliver Hagenlocher - Stampa

Red Dot Award per EMAG: La soluzione di IA EDNA perfeziona l’interconnessione nella produzione industrialeLe fabbriche del futuro sono interconnesse, sotto ogni punto di vista: le macchine comunicano tra loro gli errori o gli interventi di manutenzione necessari. Al contempo trasmettono informazioni ai pianificatori della produzione che, a loro volta, le…

30/09/2020 - Oliver Hagenlocher - Stampa

Tecnologia ad alta produttività per la mobilità elettrica: Come ottimizzare la produzione di alberi di rotore tramite pelaturaLa conversione in atto nel settore automobilistico fa sì che i responsabili della pianificazione produttiva attribuiscano sempre maggiore importanza non solo a nuovi componenti, ma anche a nuovi metodi di produzione. L'aumento della richiesta di…

14/09/2020 - Oliver Hagenlocher - Stampa

Macchina CI di EMAG ECM: soluzione altamente efficiente per la sbavatura di componenti complessiSistemi di comando e frenatura autonomi, telai idropneumatici o valori relativi al consumo notevolmente ridotti – in queste parole chiave si riflettono cambiamenti tecnologici che provocano un effetto domino in settori come quello automobilistico,…

07/09/2020 - Oliver Hagenlocher - Stampa

VLC 200 GT di EMAG: Combinazione di tecnologie per la lavorazione di moderni componenti del cambioChe il mercato della mobilità elettrica sia un settore in crescita non è certo più un mistero. Non sorprendono pertanto i risultati di uno studio condotto dalla società di consulenza Strategy Analytics, in base ai quali si prevede un aumento a…

01/09/2020 - Oliver Hagenlocher - Stampa

Centro di tornitura/fresatura VMC 450-5 MT – cinque assiComponenti di grandi dimensioni e geometrie complesse: questa combinazione non è una rarità ed è sempre sinonimo di tempi elevati e aumento dei costi. Il motivo risiede nel fatto che i diversi processi di lavorazione, dalla tornitura alla dentatura,…

17/08/2020 - Stampa

Lightweight Design for Commercial Vehicles: EMAG LaserTec is developing a holistic production solution for large truck differentialsWhen the catch phrase “lightweight design” is used for the automobile production, it typically refers to passenger cars, rarely commercial vehicles. However, there is an enormous amount of potential for weight reduction and cost savings when…

10/08/2020 - Stampa

Production system by EMAG: High-performance solutions for differential casesThe worldwide production of motor vehicles is set to rise by about two percent every year until 2030, according to the estimates of a new McKinsey study. An excellent example of how to handle these rising production volumes despite stringent quality…

16/07/2020 - Oliver Hagenlocher - Stampa

VLC 350 GT from EMAG: The perfect solution for the future of transmission and engine productions chucked partsWhat will the cars on the street look like in the future? A new study by the Boston Consulting Group forecasts a mix of gasoline and diesel engines (48 percent), hybrid vehicles (33 percent) and completely electric (19 percent). For OEM’s and supply…

15/06/2020 - Oliver Hagenlocher - Stampa

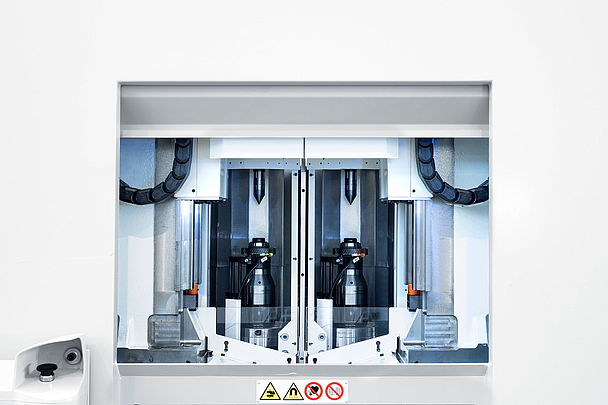

VL 1 TWIN di EMAG: riduzione massiccia dei costi per pezzo di ingranaggi coniciGli ingranaggi conici per autovetture sono componenti realizzati in massa. I subfornitori producono milioni e milioni di ruote dentate centrali per il rotismo del differenziale. Non c’è da stupirsi: in ogni singolo differenziale sono presenti quattro…

09/06/2020 - Stampa

EMAG Announces Expansion with the Opening of EMAG Charlotte!Beginning June 1, 2020, EMAG will be expanding its operation in the United States by opening an additional office, EMAG Charlotte, in Charlotte, NC. With this addition, current and prospective customers located in the southeastern portion of the…

14/05/2020 - Oliver Hagenlocher - Stampa

W 11 CNC from EMAG Weiss—Manual CNC-Supported External and Internal Cylindrical GrinderThe EMAG Group is breaking new ground with the W 11 CNC cylindrical grinder from EMAG Weiss. The company from Salach, near Stuttgart, Germany, is primarily known for its turning and grinding machines intended for high-volume production. With its W 11…

27/02/2020 - Oliver Hagenlocher - Stampa

Tecnologia per giacimenti petroliferi EMAG: Novità mondiale – Misurazione senza contatto delle geometrie delle filettature nel processo di produzioneSecondo il rapporto sull'energia del 2018 del Bundesanstalt für Geowissenschaften und Rohstoffe (BGR – Istituto federale per le Geoscienze e Risorse Naturali), il petrolio rimane la più importante fonte di energia al mondo, con una quota del 30,5%…

24/02/2020 - Oliver Hagenlocher - Stampa

EMAG Receives “Outstanding Supplier” Award from SisamexThe EMAG Group and Sisamex, a member of the Mexican Quimmco Group, have been production partners for over 20-years. At its plants in Monterrey, Sisamex produces a large variety of workpieces for trucks, agricultural and utility vehicles for many…

15/01/2020 - Oliver Hagenlocher - Stampa

EMAG acquisisce CNC-Technik Weiss GmbH con sede a NeckartailfingenCon la tecnologia di rettifica in tondo della WEISS, il gruppo EMAG amplia ulteriormente la propria gamma di tecnologie nel campo della rettifica. “Grazie alla tecnologia di rettifica WEISS ampliamo la nostra gamma di prodotti nel settore delle…

13/01/2020 - Oliver Hagenlocher - Stampa

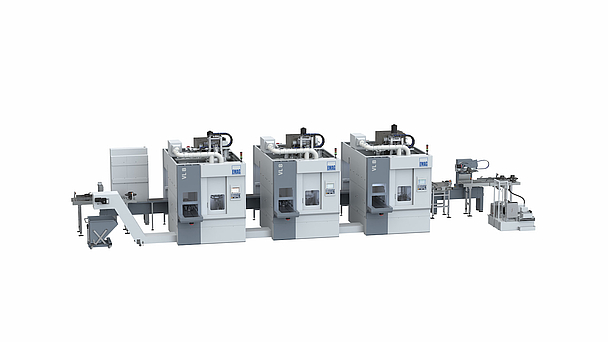

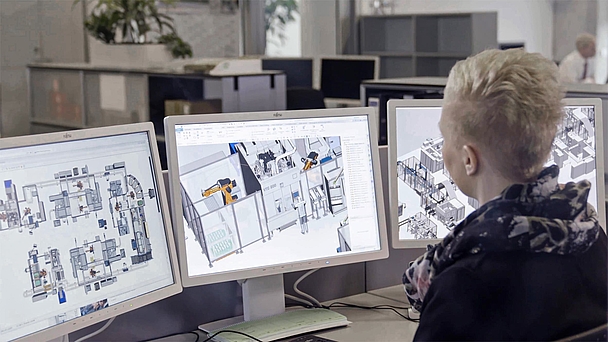

La nuova EMAG Systems: EMAG concentra il proprio know-how per soluzioni chiavi in mano "da un'unica fonte"Soluzioni di produzione da un'unica fonte – questa è la richiesta fondamentale di molti pianificatori della produzione al settore dell'industria meccanica: una impresa generale si assume la responsabilità dello sviluppo di una complessa linea di…

02/12/2019 - Oliver Hagenlocher - Stampa

Sistema di produzione EMAG: Realizzazione di un albero di rotore leggero con sistemi di produzione globaliNumerosi studi stimano una rapida crescita della mobilità elettrica. Anche le cifre sul volume di affari attuale indicano un cambiamento in questa direzione: secondo i dati forniti dal Center of Automotive Management, lo scorso anno la vendita di…

07/11/2019 - Oliver Hagenlocher - Stampa

Dentatrice a creatore R 300 di EMAG Richardon: Processi di dentatura altamente efficienti per la produzione presso l'azienda HKS Dreh-AntriebeGli azionamenti rotativi sono dei veri e propri "tuttofare": vengono utilizzati ogni volta in cui è necessario ruotare oppure orientare una massa – e questo è esattamente quanto avviene in innumerevoli veicoli commerciali, navi, macchine, centrali…

14/10/2019 - Oliver Hagenlocher - Stampa

EMAG Production System: Perfecting the Finish-Machining of Turbocharger ShaftsThe production of turbochargers is one of the most demanding tasks in automotive engineering: High-strength materials, precise geometric requirements, large quantities and price pressure are key challenges for OEMs and suppliers. The continual…

23/08/2019 - Oliver Hagenlocher - Stampa

Macchina Laser Cleaning di EMAG LaserTec: Macchina per pulizia laser LC 4-2 per l’impiego in linee di produzione o come macchina singolaEMAG LaserTec è nota soprattutto per i sistemi di saldatura laser ad alta produttività. Il concetto chiave in questo caso è la parola “sistema”: accanto al processo di saldatura vero e proprio vengono spesso integrate anche fasi di processo a monte o…

20/08/2019 - Oliver Hagenlocher - Stampa

Macchina ECM / PECM modulare – PI 800: Esecuzione ad alta efficienza di operazioni di lavorazione complesse con il processo elettrochimicoChiunque si sia già confrontato con le possibilità del processo ECM sa che si tratta di una tecnologia innovativa. Per semplificare l’accesso alla produzione con tecnologia ECM / PECM, l’azienda EMAG ECM con sede a Gaildorf presso Schwäbisch Hall ha…

12/08/2019 - Oliver Hagenlocher - Stampa

La nuova MIND-L 1000 di EMAG eldec: Riduzione dei costi di investimento e incremento della produttività per la tempra a induzioneSincronizzazione precisa, immagine termica di estrema precisione e integrazione perfetta nel processo di produzione – i vantaggi della tempra a induzione garantiscono l’utilizzo del processo in numerosi campi di applicazione dell’industria…

07/08/2019 - Oliver Hagenlocher - Stampa

Nuova macchina DUO per la produzione in serie: la VL 5 DUO di EMAG dà impulso alla produzione di componenti del gruppo propulsore con Ø fino a 250 mmProsegue la storia di successo delle macchine DUO della famiglia di prodotti Modular Solutions di EMAG. Alla EMO di Hannover l’azienda presenterà l’ultima versione della serie DUO: il tornio VL 5 DUO. Che cosa possono aspettarsi gli utilizzatori…

06/08/2019 - Oliver Hagenlocher - Stampa

EMO 2019 – Soluzioni in linea con il VL 1 TWIN: I costi per pezzo per ingranaggi planetari o ingranaggi conici si abbassano notevolmentePressione sui costi, elevati standard qualitativi e, non da ultimo, enormi quantità di pezzi – nella produzione di trasmissioni per l’industria automobilistica si contrappongono requisiti decisamente estremi. I volumi di produzione sono inoltre…

02/07/2019 - Oliver Hagenlocher - Stampa

EMAG alla EMO 2019 di Hannover: La continuazione di una storia di successoChe cosa ci riserva il futuro del settore automobilistico? Questa domanda potrebbe sintetizzare il forum tecnologico 2019 del Gruppo EMAG, che si è svolto a maggio presso la sede principale dell'azienda.

Il forum tecnologico si tiene…

05/06/2019 - Oliver Hagenlocher - Stampa

Solid-State Versus Gas Lasers – Modern Laser Production Technology for Powertrain ComponentsEven a few years back major manufacturers utilized standard CO2 lasers in factories for welding applications. Massive systems installed in separate rooms away from the actual production process supplied the energy for what, at the time, was…

29/05/2019 - Oliver Hagenlocher - Stampa

Gli esperti illustrano la rivoluzione nell’ambito dell’industria automobilisticaParole chiave come “mobilità elettrica”, “guida autonoma” e “Big Data” riassumono una svolta fondamentale nell’ambito dell’industria automobilistica globale, che va di pari passo con profondi cambiamenti della produzione – una vera e propria sfida…

20/05/2019 - Oliver Hagenlocher - Stampa

EMAG si aggiudica il premio “Axia Best Managed Companies Award”Lungimiranza strategica, capacità di innovazione, cultura dirigenziale sostenibile e buona gestione aziendale – il riconoscimento “Axia Best Managed Companies Award” stabilisce alti standard per le imprese partecipanti. Questa volta gli organizzatori…

06/02/2019 - Oliver Hagenlocher - Stampa

EMAG Automation diventa EMAG LaserTec: promuovere le tecnologie di saldatura laser e di giunzione con una nuova denominazioneLa tecnologia di saldatura laser di EMAG rappresenta da anni una straordinaria storia di successo: nella produzione di numerosi componenti complessi per autoveicoli questo processo garantisce strutture leggere efficaci e una riduzione dei costi. I…

27/04/2018 - Oliver Hagenlocher - Stampa

HLC 150 H di EMAG KOEPFER: la soluzione di dentatura a 360° per una maggiore flessibilità e costi minoriUn principio oggi più che mai attuale per l'industria automobilistica: la flessibilità della tecnologia di produzione rappresenta una delle sfide decisive che i progettisti devono affrontare. Le aziende si trovano di fronte a costanti variazioni…

![[Translate to Italian (5):] [Translate to Italian (5):]](https://cdn.emag.com/fileadmin/_processed_/d/3/csm_LinkedIn_Post_EMAG-SU_mit-Logo_1200px-x-627px_854b449ca4.jpg)

![[Translate to Italian (5):] EMAG Production System Perfecting the Finish-Machining of Turbocharger Shafts](https://cdn.emag.com/fileadmin/_processed_/2/2/csm_LineTurbocharger_Overview_8956e34f64.jpg)

![[Translate to Italian (5):] G973 G973](https://cdn.emag.com/fileadmin/_processed_/1/b/csm_G973_afbd78a961.jpg)