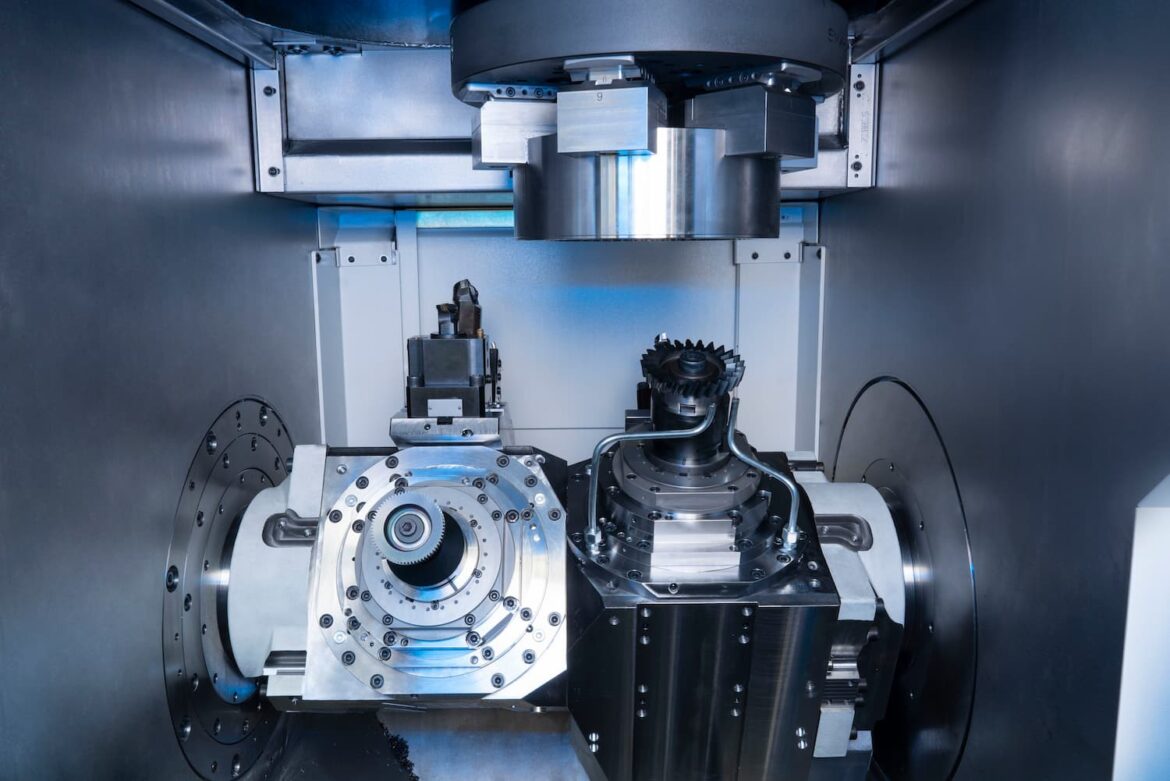

In the rapidly developing world of electromobility, precision and efficiency play a decisive role in production technology. The HLC 150 H high-performance gear cutting machine from EMAG KOEPFER represents a revolutionary solution in this context. This machine, which is characterized by its universality, precision and performance, was specially designed for the demanding task of machining tooth profiles in electric car components. With the increasing demand for quiet and efficient electric vehicles, the requirements for the machining quality of the components are also increasing. The HLC 150 H meets these challenges with advanced technology and an impressive range of machining options. In this blog post, we take a look at the special features and technical innovations of this machine and shed light on how it is driving production in the e-car sector.

Category:

Technologies

The integration of robot technology into manufacturing processes is playing an increasingly important role in the modern industrial landscape. Jan Gotthold, Product Manager at EMAG Maschinenfabrik, provides an exciting insight into this area. Using EMAG’s drive shaft production line as an example, he demonstrates the key benefits of this technology.

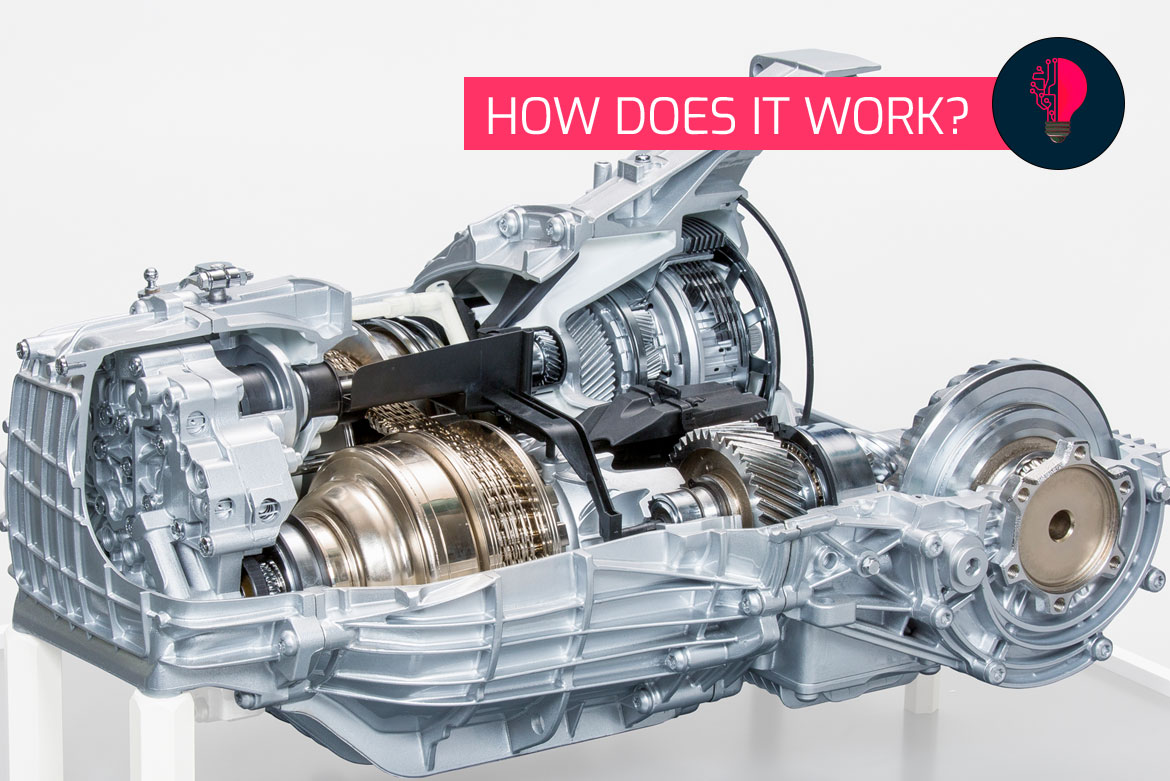

The forces in a transmission are not always transmitted with the help of gears. There are exceptions, such as the CVT transmission, in which a steel belt or a multi-plate chain moves on conical pulleys. We explain exactly how this works here. There is also some interesting information about this invention, which dates back to the 19th century.

There is no “one” big lever that can be used to improve the energy efficiency of machine tools. Instead, it is important to take a holistic view of all energy flows and that is EMAG’s approach, which the specialists apply to every new development as well as to the retrofitting of older machines. In conversation with Konrad Heimbach, Lead Engineer Energy Efficiency, it becomes clear that even relatively simple measures can massively reduce energy consumption.

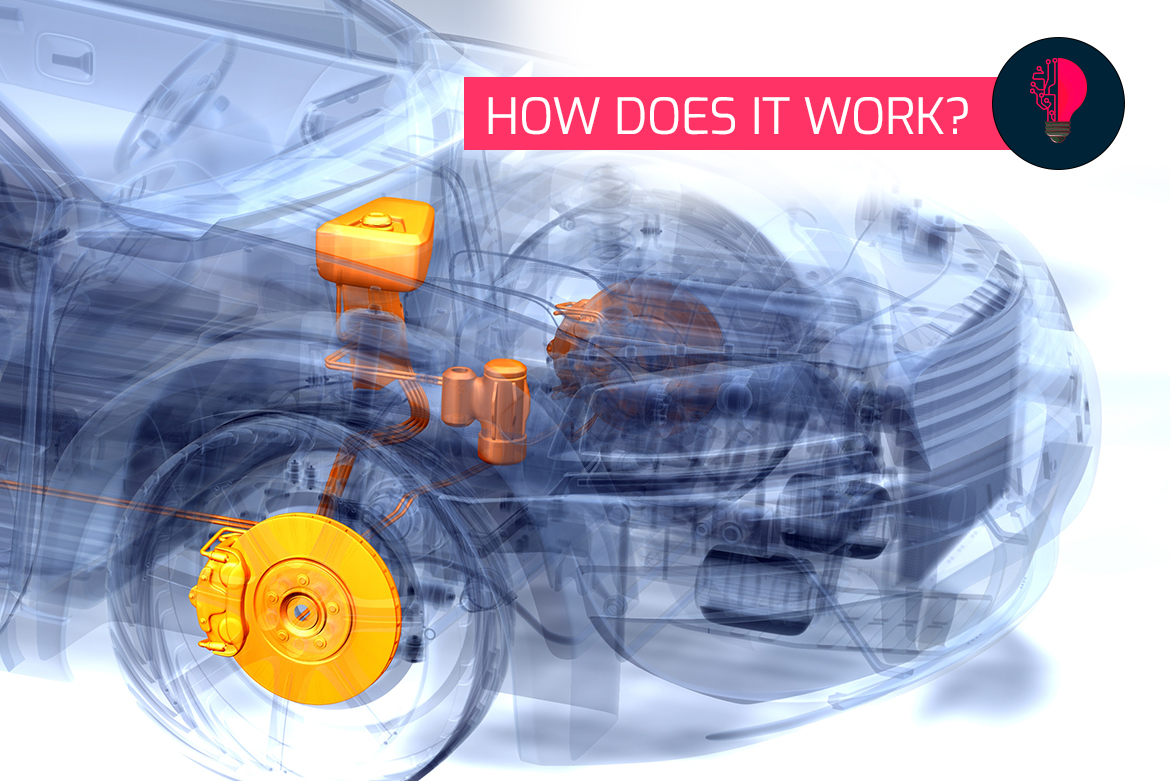

At first glance, it seems quite simple: brake pads press against the brake disk, friction is generated and the vehicle slows down – this is the basic function of the disc brake. In reality, however, a great deal of know-how goes into this car system. What is important in detail?

With the Health Check, EMAG offers its customers an IoT tool for the health assessment of feed axes and spindles in order to better plan their maintenance periods. In addition, EMAG is constantly developing this solution further, as Patrick Kaiser, data scientist at EMAG, emphasizes in the interview: “The experience and our service flow into this in a targeted manner.”

Faster than shaping, more flexible than hobbing and broaching – in this context, power skiving is a highly effective alternative for gear production. With the new VSC 400 PS machine, EMAG puts the crown on this approach by providing up to four power skiving tools and six turning tools, ensuring highly effective combination machining. And, its operation is simple. A conversation with Daniel Nille, Head of Technology Development at EMAG Maschinenfabrik, discusses the possibilities of this approach and the potential returns of investment.

The challenges for many contract manufactures and smaller manufacturing companies are increasing in the coming years – rising costs for purchasing raw materials, high energy prices and enormous OEM quality requirements point the way ahead. But there are also more and more production technology options for meeting these challenges intelligently. For example, various solutions from the latest generation of automation and robotics are highly interesting for many contract manufacturers. A conversation with Jürgen Maier, Head of the Turning Business Unit at EMAG, about the special possibilities of the EMAG approach.

What does retrofit do? The short answer – many things are possible. Depending on the customer’s wishes, the retrofitted machine not only has new components, but it is also equipped with new automation or additional tool technology. A turning machine, for example, becomes a turning-grinding center. Here we present just two examples among many possible scenarios.