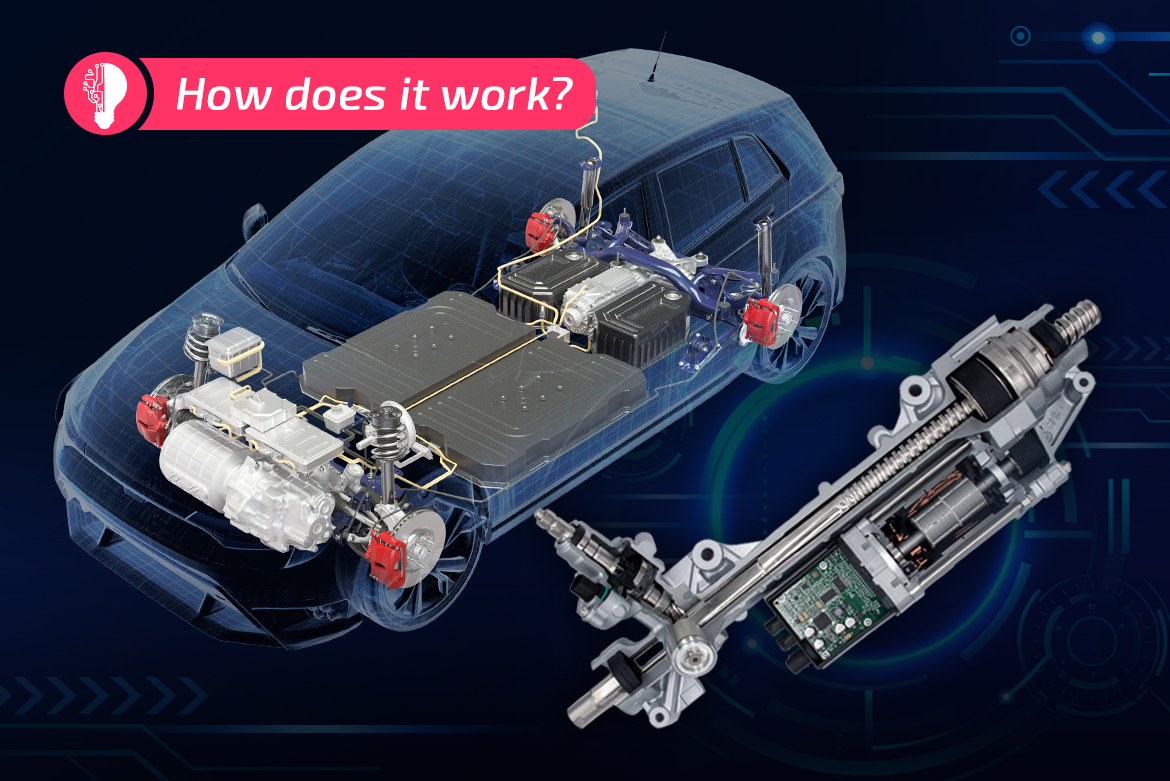

The car steering of the future will be different: largely electric and autonomous – the driver will be increasingly supported by intelligent systems. But how exactly do the various steering systems work and what role does the wheel suspension, including wishbones, play? We explain.

car manufacturing

With the introduction of the EURO 7 standard, braking systems in cars will have to undergo massive changes, as this is the first time that particulate emissions have been regulated and many current models do not meet these requirements with their brakes. What does this mean in concrete terms for automotive production, what role does the hard coating of brake discs play and why is EMAG’s new laser metal deposition technology the ideal solution? An interview with Dominic Grimminger, brake disc coating expert at EMAG.

With the new VST 50 machine, EMAG is for the first time tackling a task that is as special as it is demanding: the machining of ball pins and ball sleeves. In the steering or suspension of cars, for example, these components are indispensable. What are the details of the VST 50 and how can extreme chip-to-chip times of less than two seconds be achieved in this field? Read more about this challenge in our conversation with Dr. Mathias Klein, CSO of the EMAG Group.

In the world of machine tools, the optimal design of processes is crucial to achieving the highest precision and efficiency. In today’s blog article, we spoke to Jörg Lohmann, Head of Technology and Product Management and Member of the Management Board at EMAG KOEPFER, to find out more about how hobbing processes are designed, using planetary gears as an example. Jörg Lohmann brings almost 20 years of experience in the design and application of gear hobbing machines and gear cutting processes and gives us a deeper insight into the decision-making behind these processes.

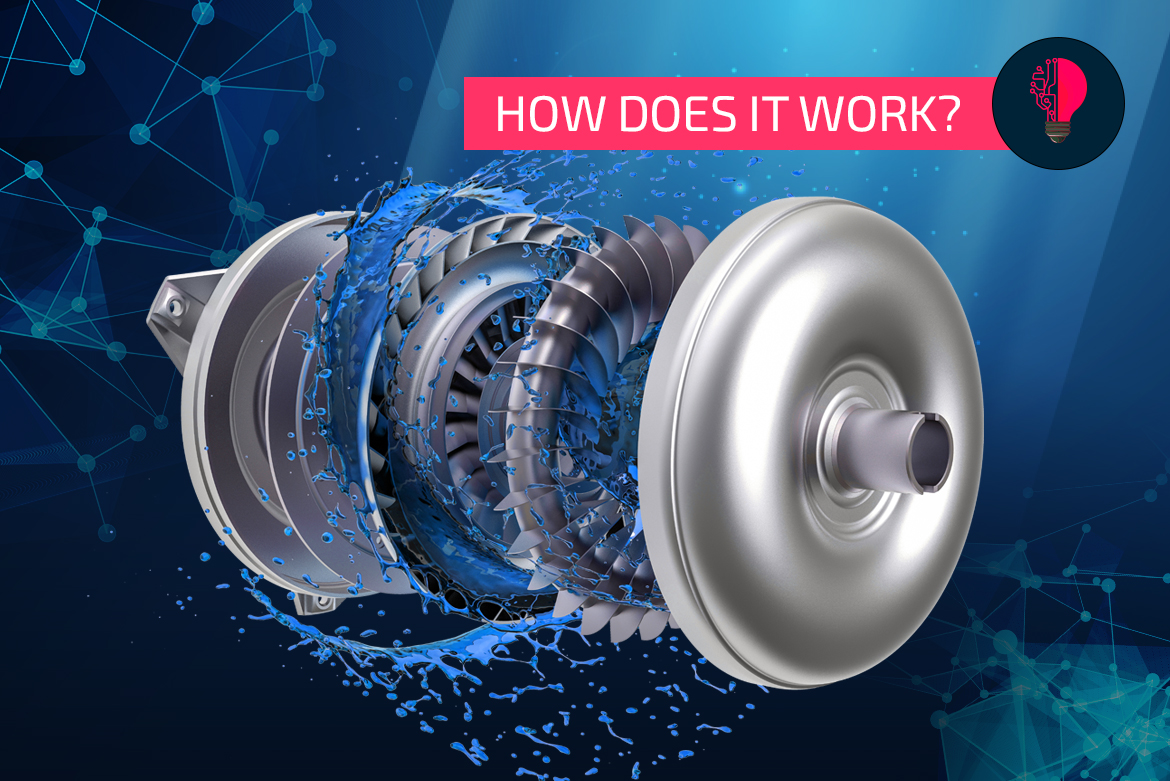

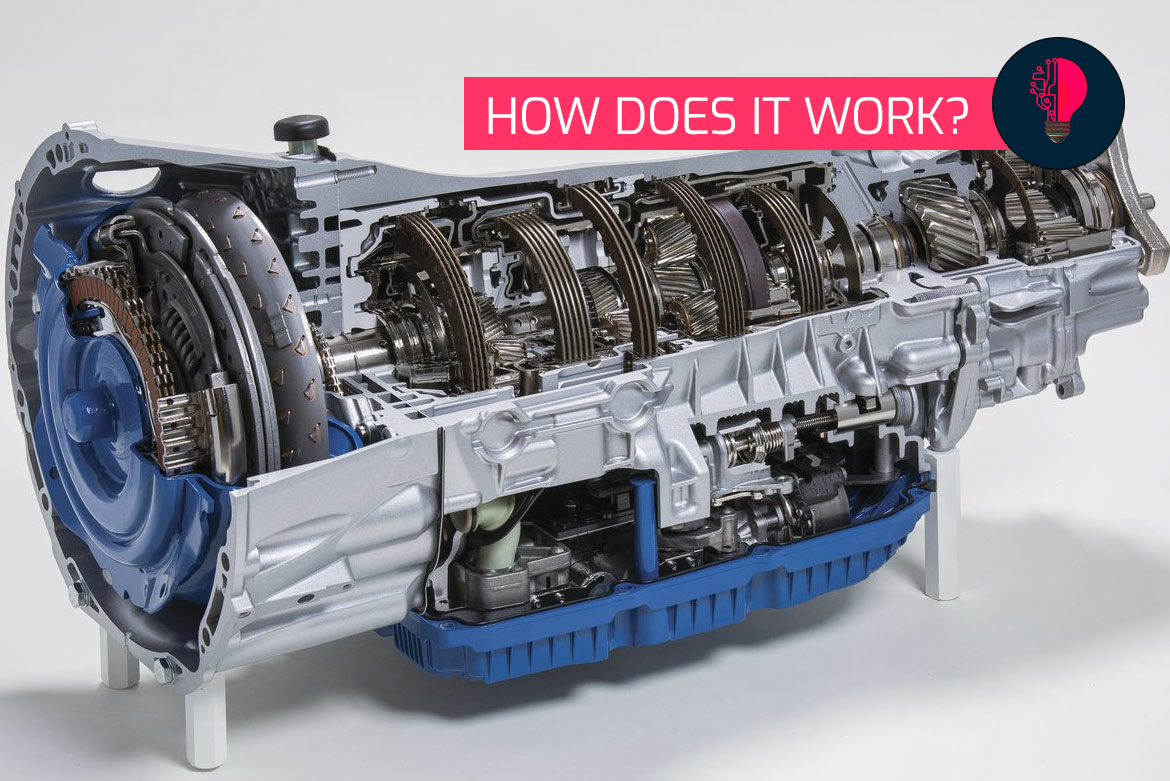

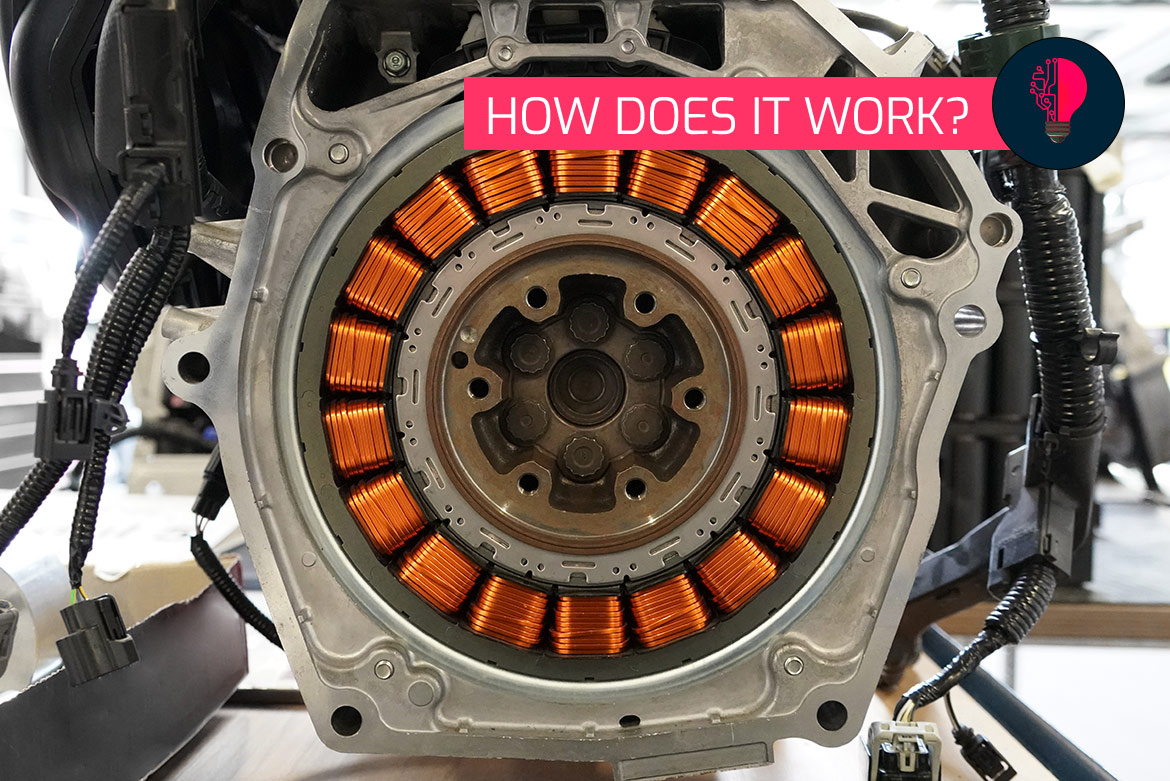

Old technology – new applications: The torque converter transmission is still “in” and is very important in automotive engineering. It is used more frequently in hybrid engines, for example. But how does the technology work and what are the advantages and disadvantages?

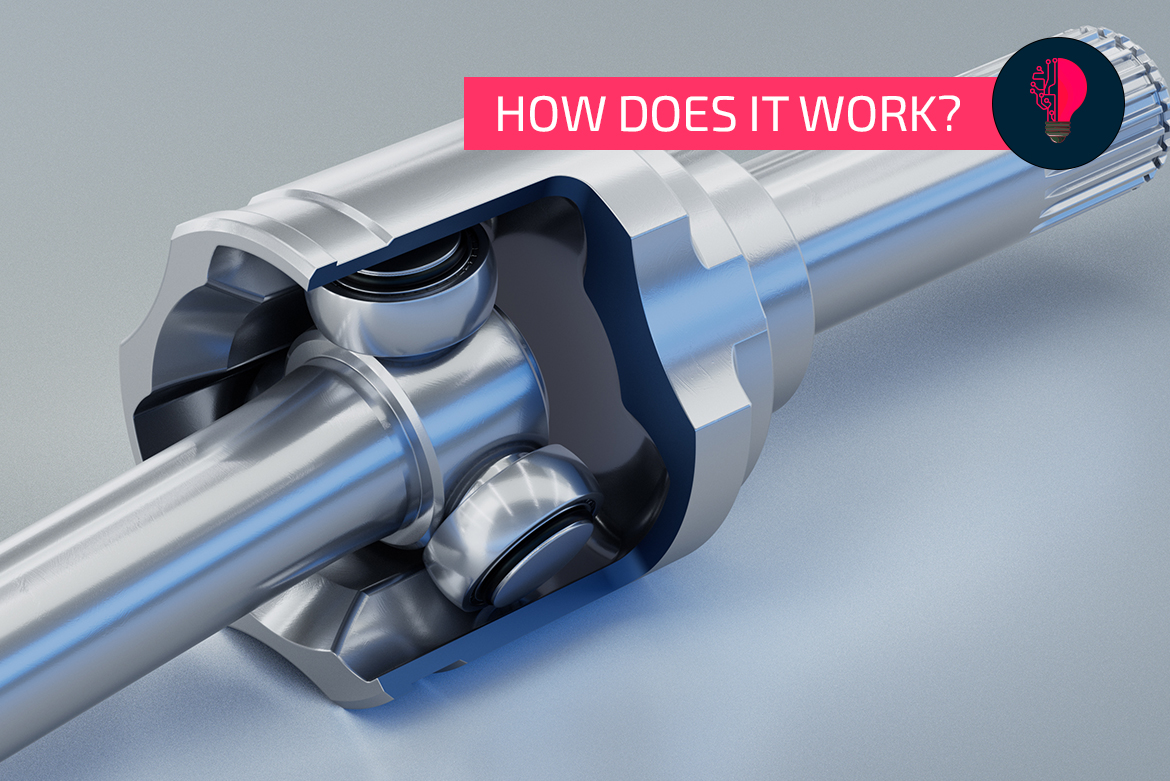

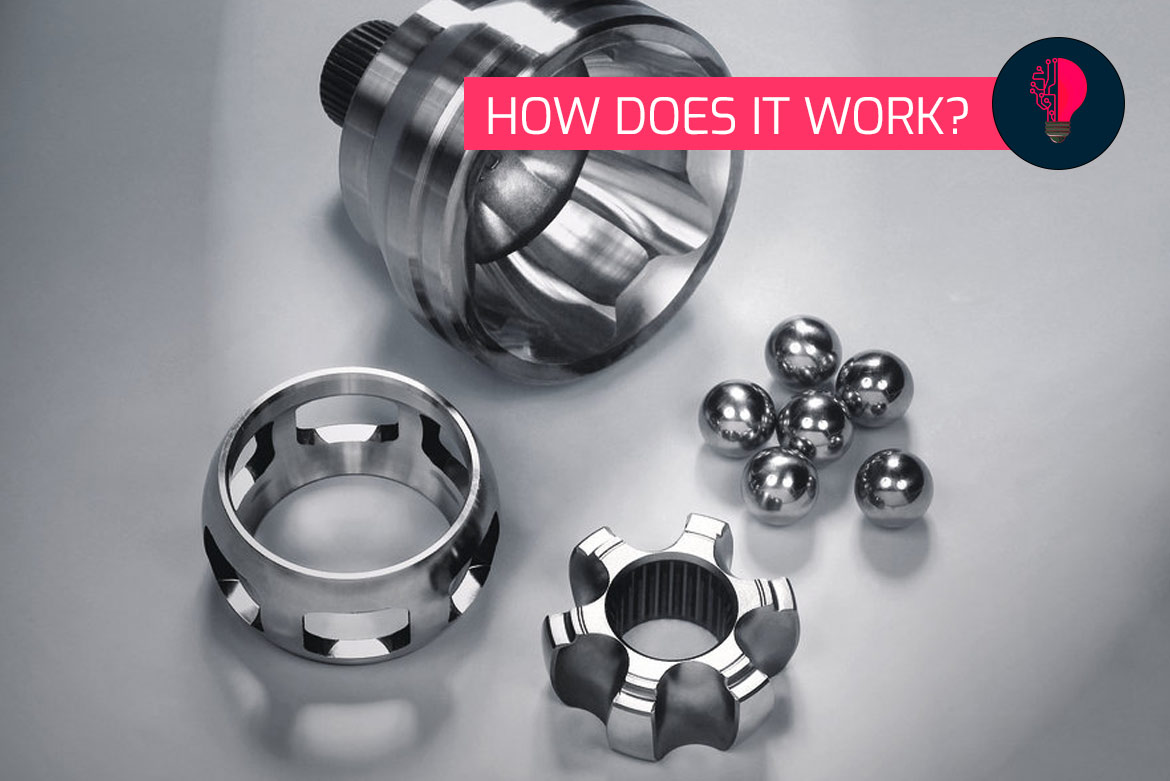

Without the tripod joint, the drive in a car would be inconceivable: The relatively small component creates the power connection between the axle drive and the drive shaft. Why is this technology so important?

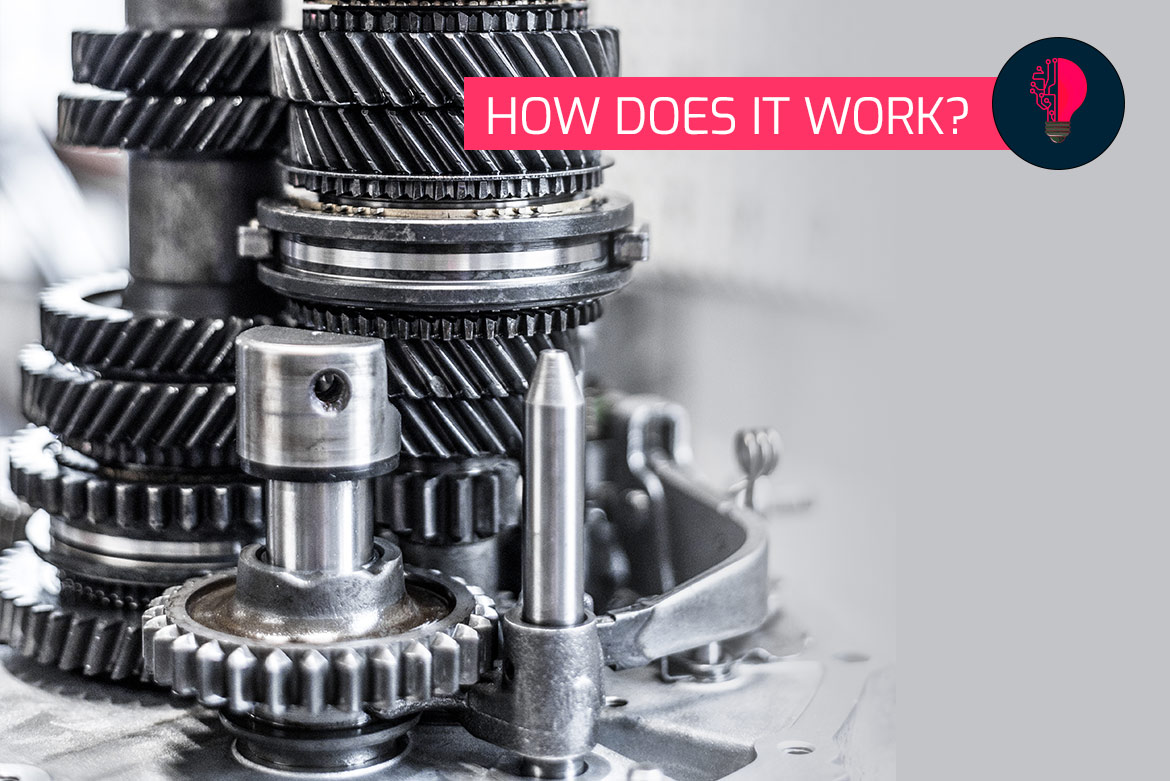

Planetary gears have been around for over 200 years – the first one was used in a steam engine at the beginning of the 19th century. The technology is still indispensable in cars, for example. What distinguishes the whole thing in detail and what are the differences in design?

CV joints are indispensable, especially in vehicle construction. Their greatest strength: they transmit the rotational movement between two shafts completely uniformly. As a result, there is no “jerking” or similar, which would put unnecessary strain on all the components involved. We have compiled some fascinating information about this invention here.