There is no “one” big lever that can be used to improve the energy efficiency of machine tools. Instead, it is important to take a holistic view of all energy flows and that is EMAG’s approach, which the specialists apply to every new development as well as to the retrofitting of older machines. In conversation with Konrad Heimbach, Lead Engineer Energy Efficiency, it becomes clear that even relatively simple measures can massively reduce energy consumption.

Tag:

Digitalization

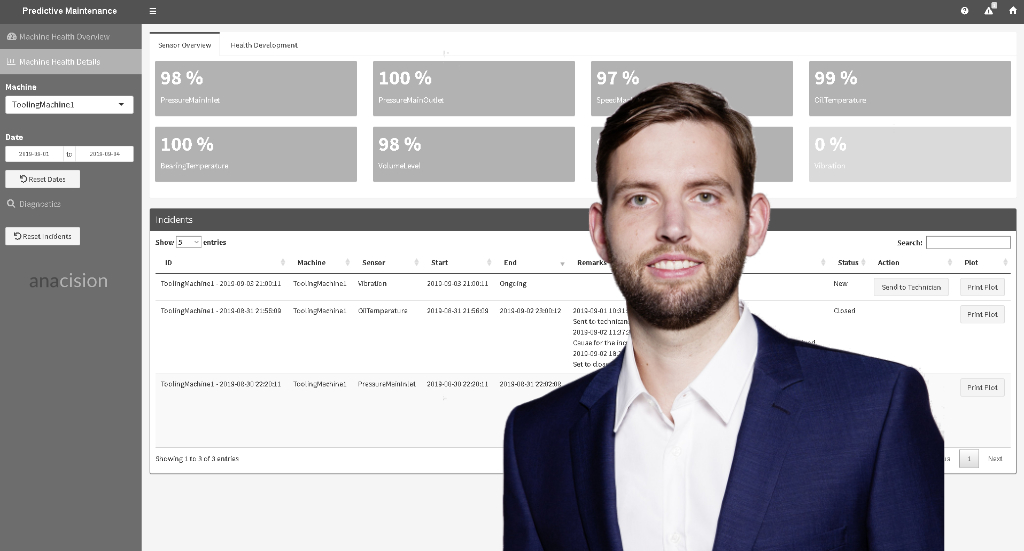

With the Health Check, EMAG offers its customers an IoT tool for the health assessment of feed axes and spindles in order to better plan their maintenance periods. In addition, EMAG is constantly developing this solution further, as Patrick Kaiser, data scientist at EMAG, emphasizes in the interview: “The experience and our service flow into this in a targeted manner.”

With the introduction of EDNA, EMAG has developed a complete ecosystem for digitizing industrial production. This required strengthening bonds between teams across company boarders – in addition to the EMAG subsidiaries, diverse external digitization specialists were involved. For this reason, we knew that we had to invite several different people to join this conversation: Peter Strohm, Business Development Manager IoT at EMAG, as well as Ricarda Schuhmann and Lukas Siegele from our partner intuit to tell us about the development process, the possibilities offered by EDNA and why they are so happy about receiving this very special award.

Data analysis and artificial intelligent are essential for the future of mechanical engineering. That is why the EMAG Group invested in anacision Gmbh from Karlsruhe, Germany last year – with the goal of developing AI products and solutions for the mechanical engineering industry. We spoke with Mr. Andreas Kühne, Senior Data Scientist at anacision, about its joint presence at the EMO with EMAG.

The transformation in the automotive industry is coming fast, and those affected should prepare now— this was the primary message at the 2019 EMAG Technology Forum. The event provided a lot of food for thought for attendees. Which key messages stood out?

Presentations at the EMAG Group’s 2019 Technology Forum

Part 3: Tomorrow’s Mobility—Connected Cars

A guest presentation by Prof. Stefan Bratzel, Center of Automotive Management

Over the next few weeks, this multi-part series will be detailing the contributions of our guest speakers at the EMAG Group’s Technology Forum, to be held on May 15 and 16 in Salach, Germany.

In this blog, we’d like to present the contribution made by Prof. Stefan Bratzel, Director of the Center of Automotive Management (CAM). The CAM is an independent scientific institute for empirical automotive and mobility research, as well as, for strategic advice at the FHDW (university of applied sciences) in Bergisch Gladbach, Germany. The institute’s research mainly focuses on questions for the future, such as e-mobility, networked vehicles, mobility services and autonomous driving. In addition, the Center of Automotive Management jointly awards the yearly AutomotiveINNOVATIONS Award together with PricewaterhouseCoopers (PwC) and thus rewards the year’s most innovative car manufacturer and supplier. The AutomotiveINNOVATIONS study identifies the future trends of automotive groups based on the CAM database of technical innovations in the automotive field.

Presentations at the EMAG Group’s 2019 Technology Forum

Part 4: Low-Emission Zones and Diesel Bans—Opportunities for an E-Mobile Future?

A guest presentation given by Prof. Matthias Klingner, Head of the Fraunhofer Institute for Transportation and Infrastructure Systems

Over the next few weeks, this multi-part series will be going into detail about the contributions of our guest speakers at the EMAG Group’s Technology Forum, to be held on May 15 and 16 in Salach, Germany.

In this blog, we’d like to present information about the contribution to be made by Prof. Matthias Klingner, Head of the Fraunhofer Institute for Transportation and Infrastructure Systems (IVI). The Fraunhofer IVI in Dresden, Germany, conducts research in the fields of vehicle and drive technology, as well as intelligent transport systems all the way to the areas of materials planning and logistics. The institute has also contributed to the development of the German mobile ticketing system, HandyTicket Deutschland, and has shown how e-mobility can be implemented in a meaningful way in public transportation with AutoTram® Extra Grand and the quick-charging electric bus.

One aspect that is often left out of the discussions about e-mobility is the corresponding transformation in car production: Planners must establish new solutions that enable efficient and holistic manufacturing of “e-components” in significantly higher unit volumes. EMAG Systems is prepared for this!

Presentations at the EMAG Group’s 2019 Technology Forum

Part 2: From Networked Production to Mobility Services – The Digital Transformation of the Automotive Industry

A presentation by Markus Turber, Managing Director of Intuity Media Lab GmbH

Over the next few weeks, this multi-part series will be exploring the exciting contributions of our guest speakers at the EMAG Group’s Technology Forum, to be held on May 15 and 16 in Salach, Germany.

In this second part, we’d like to highlight our interview with Markus Turber, Managing Director of Intuity Media Lab.

Discussions at the EMAG Group’s 2019 Technology Forum

Part 1: How Machine Tool Builders, Big Data and Digital Twin Users Benefit

A guest presentation by Prof. Michael F. Zäh from the Technical University of Munich

Over the next few weeks, this four-part series will explore the contributions of the guest speakers we have presenting at the EMAG Group’s Technology Forum, which will be held on May 15 and 16 in Salach, Germany.

In this first edition, we’d like to introduce you to the contribution by Prof. Zäh from the Technical University of Munich. Prof. Zäh has held the Machine Tools and Manufacturing Technology chair at the Technical University of Munich since 2002.

- 1

- 2