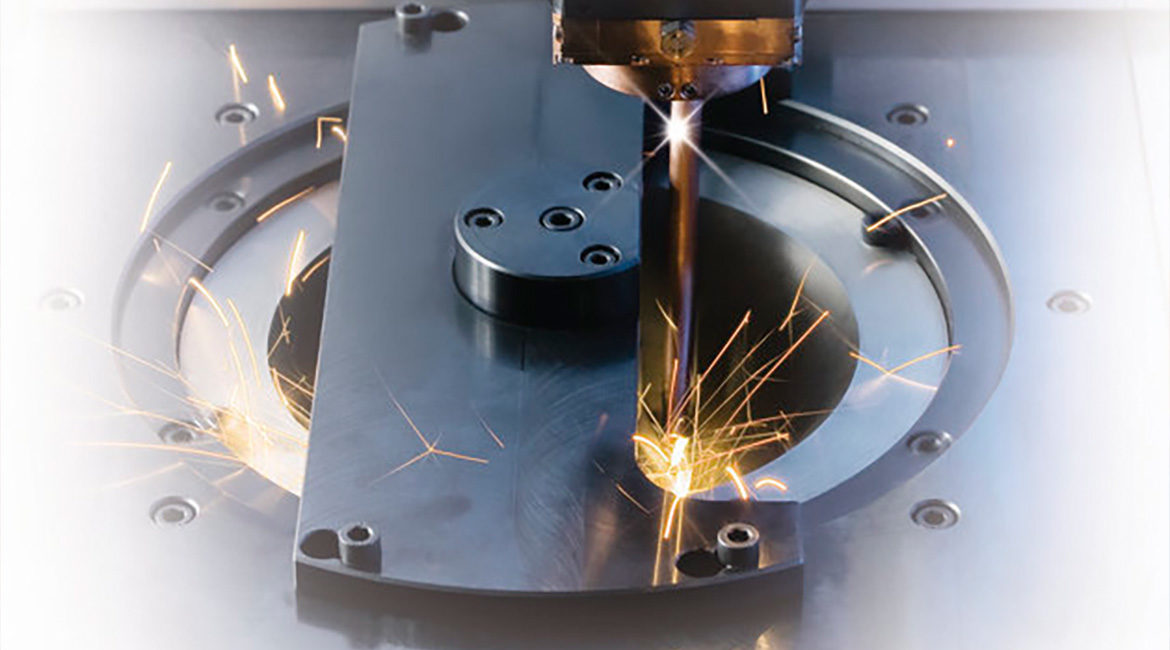

With the introduction of the EURO 7 standard, braking systems in cars will have to undergo massive changes, as this is the first time that particulate emissions have been regulated and many current models do not meet these requirements with their brakes. What does this mean in concrete terms for automotive production, what role does the hard coating of brake discs play and why is EMAG’s new laser metal deposition technology the ideal solution? An interview with Dominic Grimminger, brake disc coating expert at EMAG.

laser welding

The EMAG ELC 6 laser welding machine plays a key role in the production of drive components for electric motors. In our interview with Konrad Eibl, you will gain a deeper insight into how the ELC 6 works, the technical aspects and the wide range of possible applications. You will learn how this innovative machine contributes to increasing efficiency in production and what role it will play in the future of manufacturing technology. Particular attention will be paid to the production of rotor shafts, a critical element in the rapidly growing electromobility industry, where precision and process reliability are highly important.

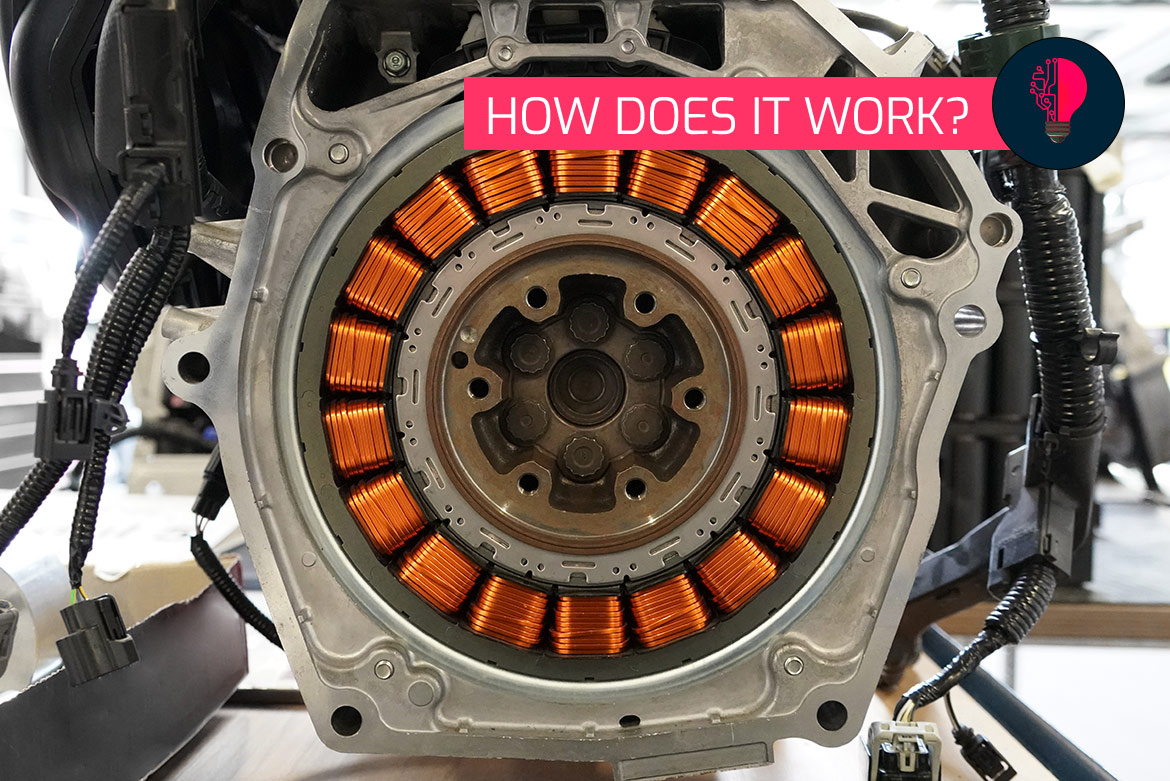

The future is “under power”: electric motors will be used in many places in the future – from cars to heating systems – in order to avoid the consumption of fossil fuels. The basic principle of a conventional electric motor is always the same: magnetic fields drive a shafts. How exactly does it work?

Lightweight design in the commercial vehicle industry? For years, this question was unimportant to truck developers. They were more focused on the stability of the vehicle as it was expected to provide reliable service for decades. However, with a new focus on CO2 emissions, this view is changing and the industry is looking for a way to keep the vehicles stability, but while also incorporating a lightweight design.

“Smart technologies drive tomorrow’s production!” That is the motto for EMO 2019 in Hanover, Germany. But we believe that smart people, and not just smart technologies, are what matters—and we need to bring those people together to talk.

So, at the EMAG Group’s booth, we will be focusing not just on networked technologies, but also on networking with our visitors.

To give you a preview of who you really should talk to at the EMO, over the next few weeks we will be publishing regular interviews with the EMAG experts who will be there in person.

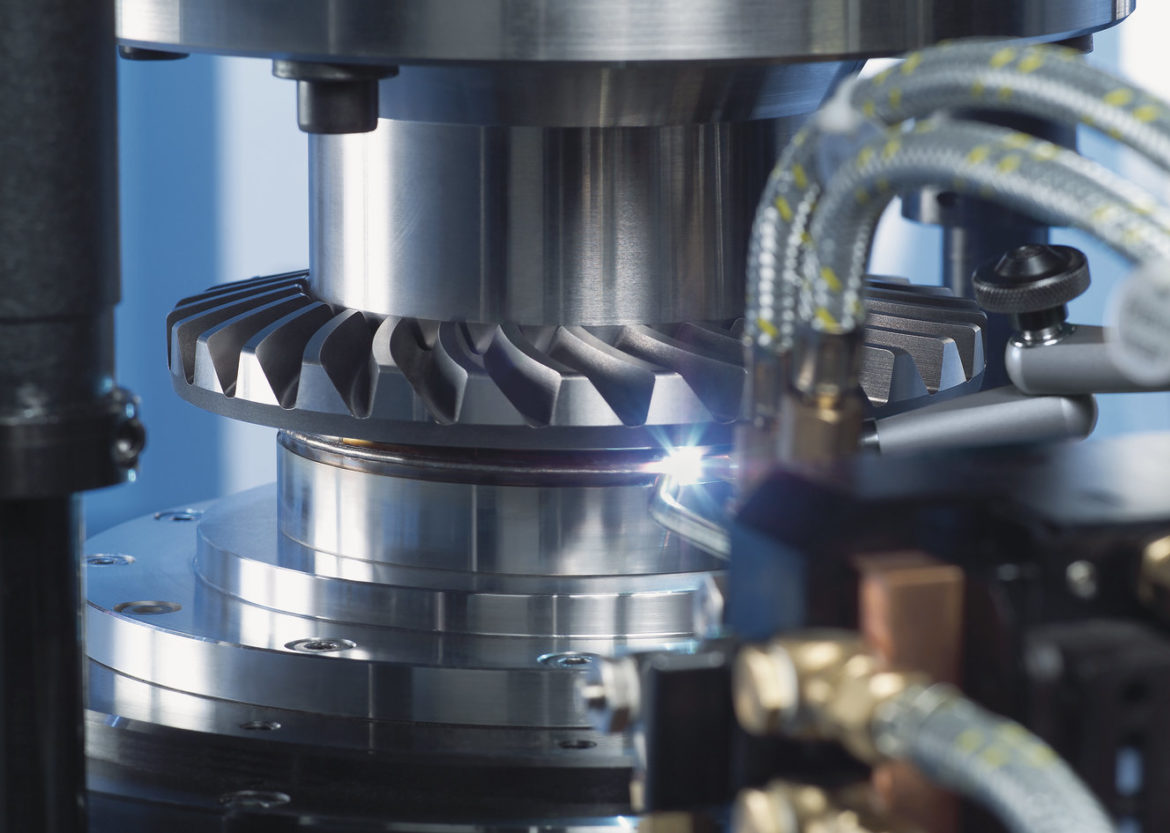

EMAG laser technology has become essential in the production of modern transmission components – the ELC machines (EMAG Laser Cell) enables effective lightweight car construction with lower component costs. The laser specialists from EMAG based in Heubach, near Stuttgart, have changed their name to “EMAG LaserTec”. What’s the reason for the change? – An interview with EMAG LaserTec Managing Director Andreas Mootz about growing success, new technologies and promising applications explains.

Lightweight construction in the automotive industry is a fight for every pound. Every single part is investigated for whether it could be made even lighter. This is typically accomplished by using new materials of changing part geometries. Laser welding offers a surprisingly simple strategy, e.g. by enabling a stable connection between differential gear and ring gear. This saves screw connections and reduces weight by 1.2 kg – quite an accomplishment by the standards of the field.

EMAG ELC 250 helps with mass reduction with the laser welding of differential parts.

EMAG had seen that the world automobile market was pushing suppliers to decrease mass and reduce the overall size of driveline systems, specifically differentials. More of todays automobiles are offering an all-wheel drive or on demand four wheel drive system that require an added differential.

New EMAG Press Release: Complete laser welding solutions for transmission manufacturing

In the automotive industry, one trend has been consistent for years: Passenger vehicle transmissions are becoming smaller and lighter, although the number of speeds—and of toothed gear components—continue to increase. How does the entire assembly not become heavier?