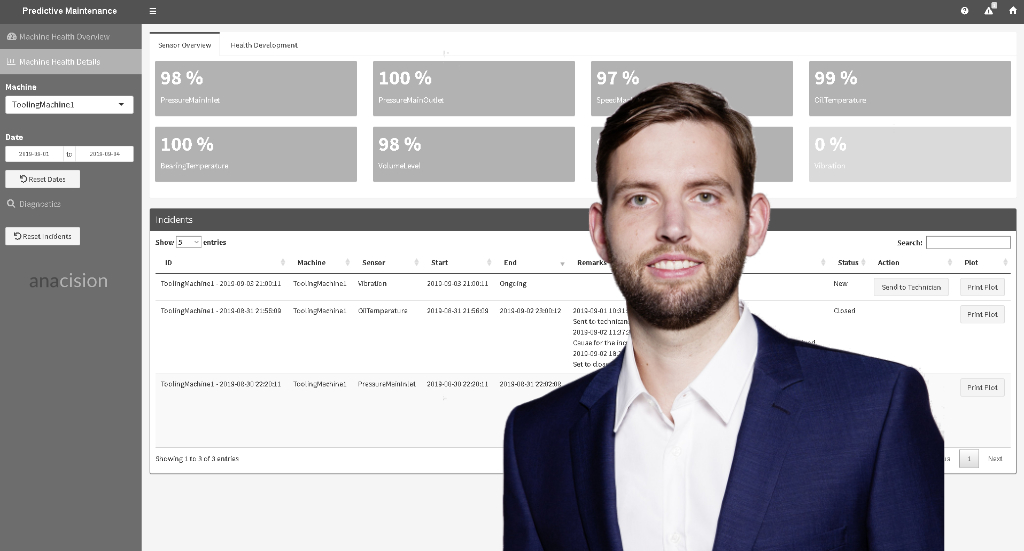

Data analysis and artificial intelligent are essential for the future of mechanical engineering. That is why the EMAG Group invested in anacision Gmbh from Karlsruhe, Germany last year – with the goal of developing AI products and solutions for the mechanical engineering industry. We spoke with Mr. Andreas Kühne, Senior Data Scientist at anacision, about its joint presence at the EMO with EMAG.

EMO 2019

“Smart technologies drive tomorrow’s production!” That is the motto for EMO 2019 in Hanover, Germany. But we believe that smart people, and not just smart technologies, are what matters—and we need to bring those people together to talk.

So, at the EMAG Group’s booth, we will be focusing not just on networked technologies, but also on networking with our visitors.

To give you a preview of who you really should talk to at the EMO, over the next few weeks we will be publishing regular interviews with the EMAG experts who will be there in person.

“Smart technologies drive tomorrow’s production!” That is the motto for EMO 2019 in Hanover, Germany. But we believe that smart people, and not just smart technologies, are what matters—and we need to bring those people together to talk.

So, at the EMAG Group’s booth, we will be focusing not just on networked technologies, but also on networking with our visitors.

To give you a preview of who you really should talk to at the EMO, over the next few weeks we will be publishing regular interviews with the EMAG experts who will be there in person.

“Smart technologies drive tomorrow’s production!” That is the motto for EMO 2019 in Hanover, Germany. But we believe that smart people, and not just smart technologies, are what matters—and we need to bring those people together to talk.

So, at the EMAG Group’s booth, we will be focusing not just on networked technologies, but also on networking with our visitors.

To give you a preview of who you really should talk to at the EMO, over the next few weeks we will be publishing regular interviews with the EMAG experts who will be there in person.

Networking @ EMO:

Series of interviews with the experts at the EMAG Group with whom you can exchange views at the EMO

“Smart technologies drive tomorrow’s production!” That is the motto for EMO 2019 in Hanover, Germany. Yet, we are convinced that not only smart technologies are important, but above all, so are smart people—and they must be brought together to talk to one another.

That is why we will not only focus on networked technologies at the EMAG Group’s booth, but also on networking with our visitors.

In order to let you look ahead and find out whom you absolutely should talk to at the EMO. In the coming weeks, we will regularly interview our experts who will also be attending the EMO in Hanover.

Networking @ EMO: A Series of Interviews with EMAG Group Experts

“Smart technologies drive tomorrow’s production!” That is the motto for EMO 2019 in Hannover, Germany. But, we are convinced that not only are smart technologies important, but smart people are also important! And it is essential that these people come together to talk to one another.

That is why we will not only focus on networked technologies at the EMAG Group’s booth, but also on networking with our visitors.

To allow you to plan ahead and figure out who you need to speak with at EMO, we will be releasing a series of interviews in the coming weeks with our industry experts that will be attending EMO.

In the past year, for the first time ever, more than 2 million electric vehicles were sold worldwide as reported by the Center of Automotive Management (CAM). With 60% of the worldwide demand, China is the main driver of this development.

Large components and complex geometries—in heavy machining, this combination is far from being rare and always synonymous with a high expenditure of time and rising costs. The reason is that the various machining processes from turning to gear cutting are frequently performed in different machines that are not entirely interlinked with one another.

With its vertical turning/milling center VMC 450-5 MT, EMAG Leipzig breaks the vicious circle in an impressive manner: All turning, milling, drilling and gear cutting processes take place in a single machining area. To achieve this, the machine is equipped with five axes. This results in shorter throughput times and a minimal tooling effort—with increasing component quality and diversity.

How can commonly mass-produced transmission components, such as planetary gears be produced even more efficiently? The EMAG Group provides a customized answer to this question with the development of the twin-spindle pick-up turning center, VL 1 TWIN. It machines two identical components simultaneously in the same machining area. This technology opens up a wide range of possibilities: When two machines are combined in a line, the planetary gear can be machined from two sides—and all that is completed with shorter cycle times. What exactly does the line solution for planetary gears look like?

The HLC 150 H horizontal gear cutting machine by EMAG KOEPFER is the perfect complete solution for machining workpieces up to module 3 with a maximum length of 500 mm (20 in). It not only features all relevant gear cutting technologies such as gear hobbing, skiving, screw milling and worm skiving, it also includes press deburring and chamfering integrated into the machining area. As a result, an extremely wide range of workpieces can be finished without burrs – including gear and anchor shafts, steering pinions, planetary gears and worm gears.