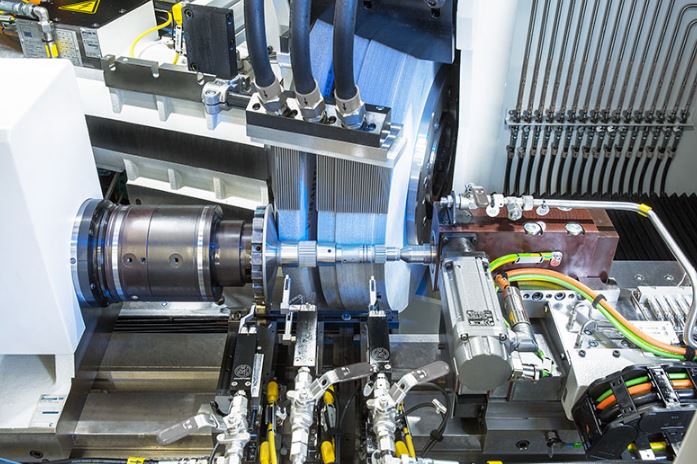

Precise, compact and cost-effective – these are the criteria that have made the WPG 7 external cylindrical grinding machine from EMAG WEISS a great success on the market. It requires minimal floor space and can also be installed quickly, but at the same time features a whole range of high-tech components for flexibility and productivity. What characterizes the machine in detail? Our grinding expert Andreas Holstein provides the answers in this interview.

Grinding

Find out more about the design and development of the VLC 350 GT turning/grinding center in our interview with Manfred Winkler, Head of Technical Sales, Business Unit Grinding. The VLC GT series from EMAG is one of the most successful new developments in recent years. The combination of proven pick-up automation, vertical machining and the ability to use various hard machining technologies in the spacious work area has made some great manufacturing solutions possible. We spoke to Manfred Winkler about the machine and the ideas behind the new development.

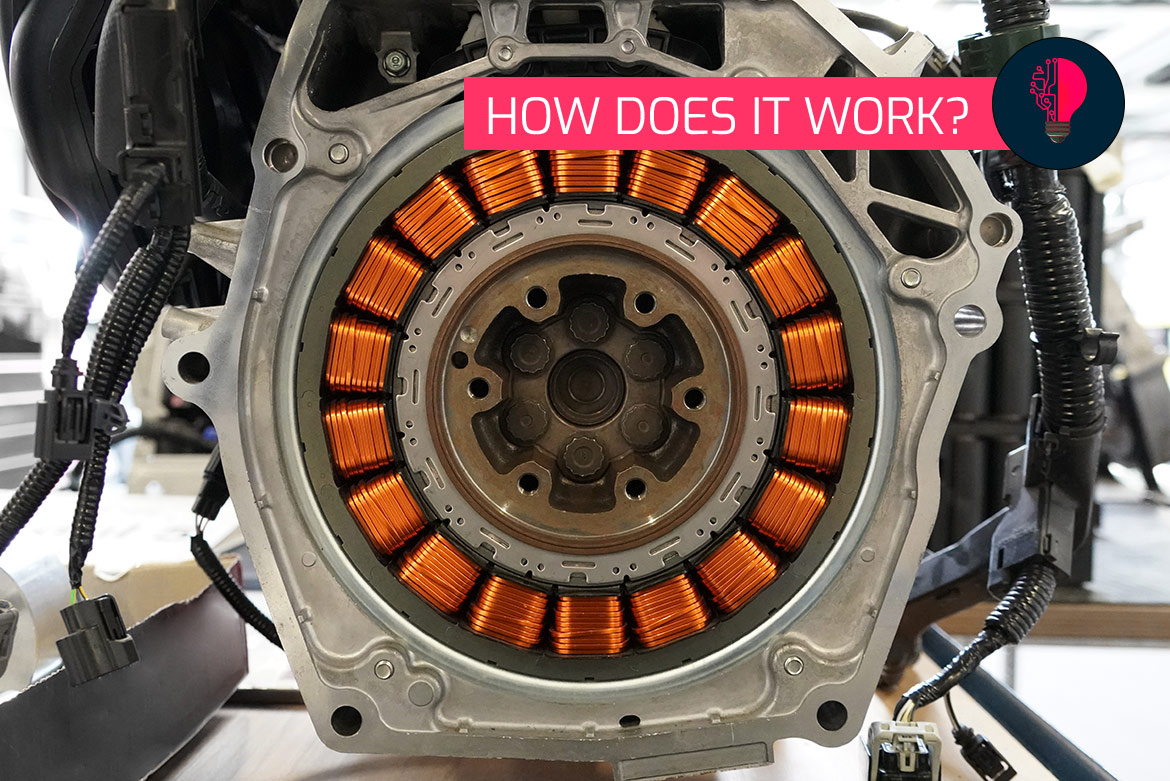

The future is “under power”: electric motors will be used in many places in the future – from cars to heating systems – in order to avoid the consumption of fossil fuels. The basic principle of a conventional electric motor is always the same: magnetic fields drive a shafts. How exactly does it work?

The integration of robot technology into manufacturing processes is playing an increasingly important role in the modern industrial landscape. Jan Gotthold, Product Manager at EMAG Maschinenfabrik, provides an exciting insight into this area. Using EMAG’s drive shaft production line as an example, he demonstrates the key benefits of this technology.

Development of the new VLC 350 GT Turning/Grinding Center – Interview with Marina Manger

The VLC GT series is one of the most successful new product developments for EMAG in recent years. The combination of the proven pick-up automation system, vertical machining operation and the option of using different technologies for hard machining in the spacious machining area, has made some fantastic production solutions possible.

With the VLC 350 GT, the next biggest expansion stage is being launched. We spoke to Marina Manger, assistant team leader of the TPM-1 application team, about the new machine and the ideas its development was based on.

CNC-Technik Weiss GmbH joined the EMAG Group at the end of 2019. We’ll interview Bernd Weiß, the company’s Managing Director, to learn more about the company, as well as the plans for the development of new cylindrical grinders.

Cylindrical grinding on driveshafts and transmission shafts has always been particularly demanding, as the parts feature a wide range of geometric details that are machined with high precision in the grinding machine. With the rapid pace of technological development in the automotive industry, which keeps increasing the functional density of many components, there are more demands than ever on the design of grinding machines today. Users require highly customized machines that can perform multiple grinding operations, including combined internal and external grinding.

The automotive world is constantly changing and improving. The industry strives to create vehicles with better fuel economy, while also increasing safety and reliability.

The introduction of hybrid and electric alternatives are becoming more popular, and in the years to come we will see these options continue to grow. With this change, certain components of today’s gas driven engines will be replaced with new components and technologies.

Transmission manufacturing is among the most innovative areas of passenger vehicle production: This central component has to ensure a high level of driving dynamics, while keeping fuel consumption low at the same time. Transmissions are therefore becoming smaller and lighter, and provide a higher number of speeds. The individual gearwheels are a main focus of the developers. Their production in extremely high volumes requires a high level of efficiency—at high precision, high speed, and highly controlled.