CNC-Technik Weiss GmbH joined the EMAG Group at the end of 2019. We’ll interview Bernd Weiß, the company’s Managing Director, to learn more about the company, as well as the plans for the development of new cylindrical grinders.

Mr. Weiß, how did you make the decision for your company to become part of the EMAG Group?

There were actually several reasons for that, but the main reason was that we had reached the limit of our capacity here in Neckartaifingen. Our order books are full and only a strong partner could help us continue to grow. EMAG made it possible.

What were the other motives?

I’m familiar with EMAG and of course I’ve also known many of the employees and managing directors in Salach for a number of years. We were always on friendly terms. And I know about the great expertise that EMAG has built up in the area of grinding technology. That is why I assumed that here at Weiss, and the colleagues in Salach would both benefit from an active partnership working toward the advancement of cylindrical grinding technology and grinder construction. Particularly with grinder construction, the partnership would provide a huge relief to our site because in the future we want to have our W11 CNC cylindrical grinder manufactured at the EMAG Zerbst production company. This will allow us at EMAG Weiss to focus on the retrofit for Karstens and the engineering of customized cylindrical grinders.

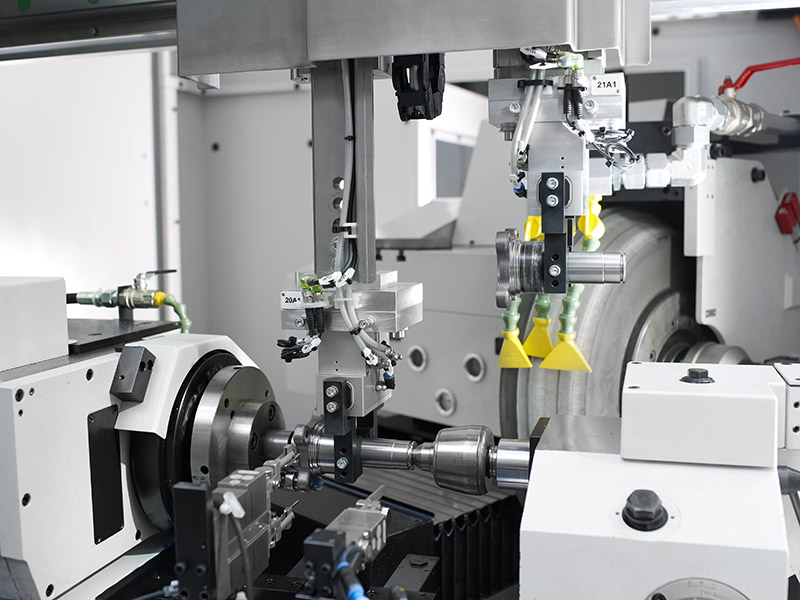

The EMAG Group is expanding its technology range in the field of grinding with cylindrical grinding technology from WEISS.

How will the division of business look? For example, in the case of Service and Sales?

Not much will change here at first. We will begin to transfer the standard W11 CNC cylindrical grinder machine range into the EMAG structure. Meaning that the machines will be built in Zerbst, and all sales and service relating to this machine will be handled by the EMAG Group’s network. Service and sales relating to the design, engineering and manufacturing of custom machinery as well as retrofitting will continue to be handled through our headquarters here at Weiss. Customers shouldn’t worry; they can call us or EMAG and will be forwarded to the appropriate person. That’s handled without red tape.

What can the customer expect from the new Weiss W11 CNC cylindrical grinder?

The best of both worlds! Even though we’ve only been engineering machines for about 10 years, the word has gotten out about the quality of our cylindrical grinders – both in regards to the machines and the parts they produce. With the help of the EMAG Group, we plan to convince even more customers around the world of the benefits for the W11 CNC cylindrical grinder. The machine is designed for workpieces with an outside diameter of up to 350 mm (14 in) and can be used for external, internal as well as face grinding. We will present the first machines built in Zerbst sometime this year. The long-term goal is to build more than 100 CNC cylindrical grinders per year.

Is there anything else you would like to tell our readers?

I would like to assure our customers that for now, everything will remain the same in terms of contacts and customary processes. As previously mentioned, the biggest changes will be centered on the W11 CNC cylindrical grinder standard machine line. Hopefully, this interview will have provided some insight into our company to all those who are not yet familiar with us. I am looking forward to making many new contacts this year.

Mr. Weiß, thank you very much for talking to us.