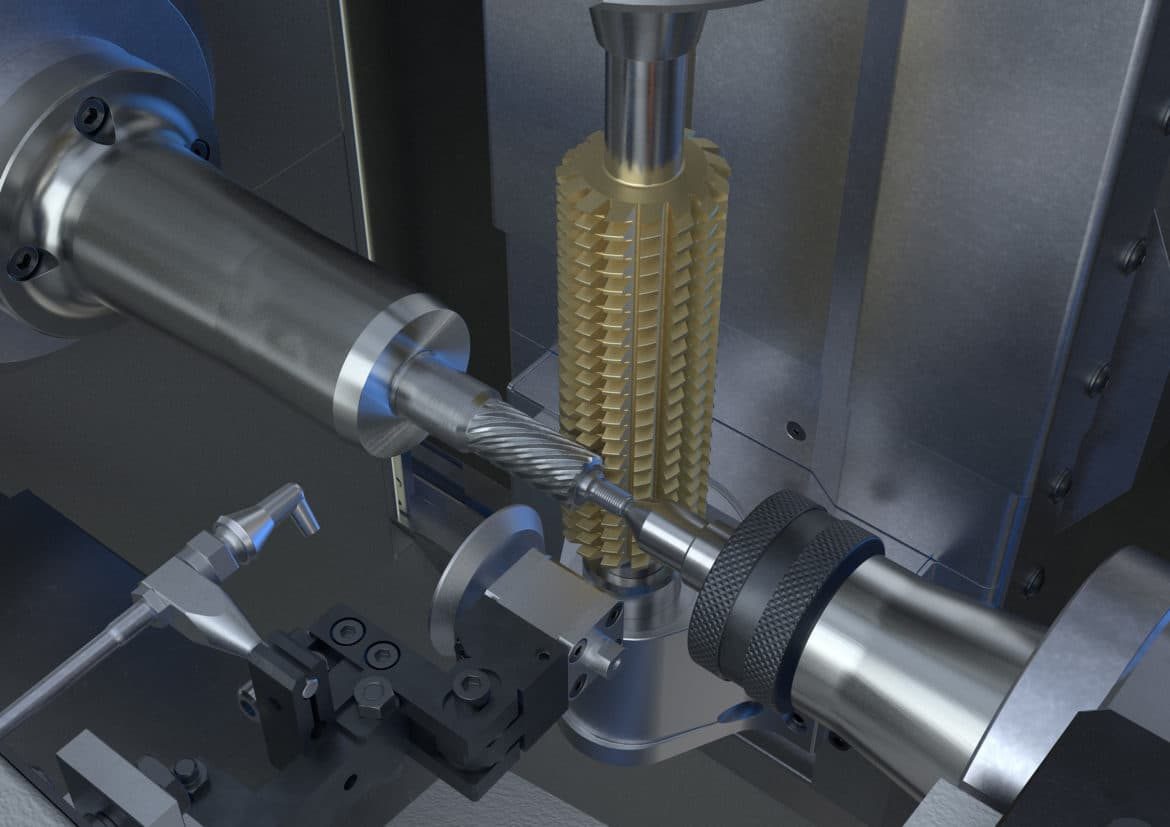

The HLC 150 H horizontal gear cutting machine by EMAG KOEPFER is the perfect complete solution for machining workpieces up to module 3 with a maximum length of 500 mm (20 in). It not only features all relevant gear cutting technologies such as gear hobbing, skiving, screw milling and worm skiving, it also includes press deburring and chamfering integrated into the machining area. As a result, an extremely wide range of workpieces can be finished without burrs – including gear and anchor shafts, steering pinions, planetary gears and worm gears.

steering pinion

Electric power steering has become standard in the manufacturing of automobiles. The technology guarantees very precise steering support for every type of vehicle, high-end driving comfort, and lower energy consumption in the steering system, which has a positive effect on the car’s CO2 consumption.

The revolution in car manufacture is happening subtly: Our cars are mastering an increasing number of situations without driver intervention. There is a large number of assistance systems which keep the vehicle on track or avoid obstacles. Recent models even park independently or drive into the garage. This requires the driver to take their hands off the steering wheel entirely. Experts divide the current development into phases: The assistance systems described above have already become a reality. As a partially automated system, parking assistance belongs to phase two. In a few years, fully automatic, driverless operation will follow as the last phase.

Maximum flexibility is required for gear production. EPS steering is a good example: Production planners for this application are looking for machines that can efficiently and completely cut an EPS steering gear including steering pinion, worm gears, and screws. The HLC 150 H horizontal gear cutting machine from EMAG KOEPFER is the perfect solution for this.