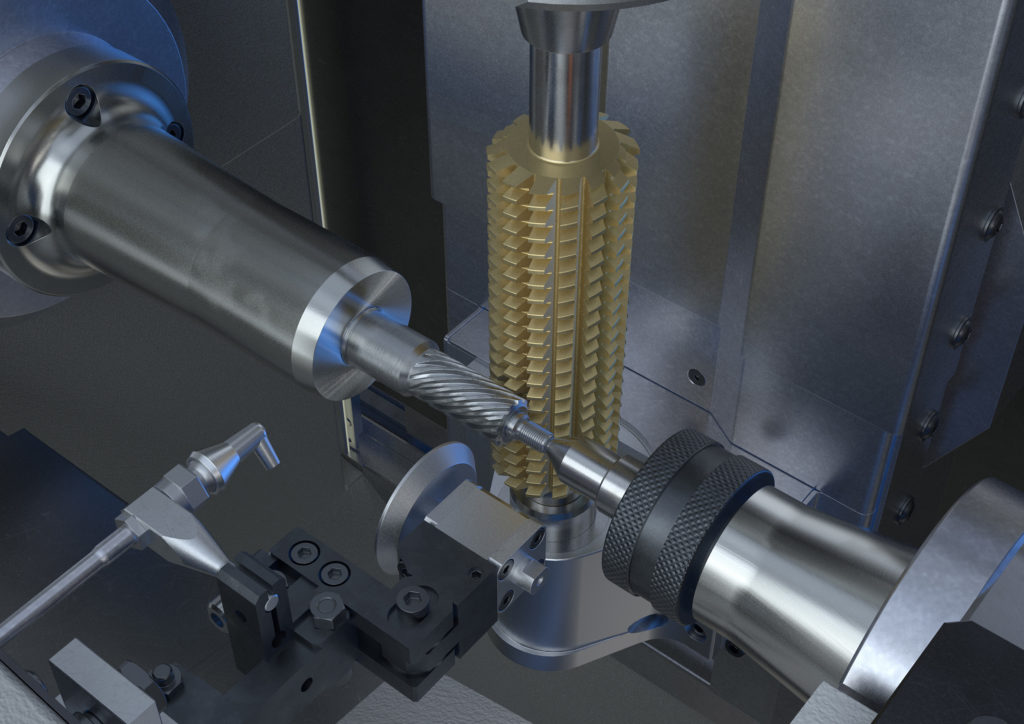

The HLC 150 H horizontal gear cutting machine by EMAG KOEPFER is the perfect complete solution for machining workpieces up to module 3 with a maximum length of 500 mm (20 in). It not only features all relevant gear cutting technologies such as gear hobbing, skiving, screw milling and worm skiving, it also includes press deburring and chamfering integrated into the machining area. As a result, an extremely wide range of workpieces can be finished without burrs – including gear and anchor shafts, steering pinions, planetary gears and worm gears.

High-Quality Gear Cutting

Component quality and process reliability are ensured, first by the cutter head. It has a very rigid suspension, and always completely moves during the machining operation. The shift axis is based on the interpolation of two axes. This results in a large swivel angle for the cutter head, and, at the same time, a large shift path. This process allows the gear hobbing to run very smoothly, and guarantees high gear cutting quality. Another important feature is the ability of the chips to fall downward freely, preventing chip build-up. For chip discharge, a variety of solutions are available including scraper-belt or permanent-magnetic conveyors – with the option of a deep-bed filter with magnetic pre-separator drum for ferromagnetic materials, non-ferrous metals, and plastic.

Complete gear hobbing machine HLC 150 H

Lower Cost Gear Cutting

The HLC 150 H also reduces costs in many ways: Its frequency-controlled hydraulic units are very energy-efficient and the media supply is only activated when required. Additionally, the quick-clamping system and accessibility of the machine allows tools to be changed very quickly and efficiently.

Range of Workpieces for the HLC 150 H

A complete solution in every respect – the high performance HLC 150 H gear cutter can machine a large range of workpieces, from armature shafts and pinions, gear wheels, planetary gears, worm gear wheels and worm gears to transmissions shafts with a maximum length of 500 mm (20 in).

The high performance gear cutter HLC 150 H can machine a large range of workpieces, from armature shafts and pinions, gear wheels, planetary gears, worm gear wheels and worm gears to transmissions shafts.

Integrating into Lines with Automation

The HLC 150 H also includes a largely modular automation system: Lighter components of up to 3 kg (7 lbs) are handled by an integrated high-speed gantry loader with rotating twin gripper. For heavier workpieces up to 10 kg (22 lbs) a V-shaped linear gripper is available. The machine can be integrated into a complete EMAG production line at any time.