When the conversation turns to the topic of sustainability, most would assume green manufacturing and environmental protection will be the focus of the discussion. It’s part of the chat, Michael Tamasi, President and CEO of AccuRounds, argues, but to him and his company the term means much, much more. Yes, they’ve added solar panels to lower the plant’s carbon footprint; however, Michael knew building a company that will last involves attracting, developing and keeping talented staff. Retaining good employees also requires nurturing a creative and caring culture, and of course, operating a profitable business that provides long-term financial security as well as a good wage.

Tag:

automation

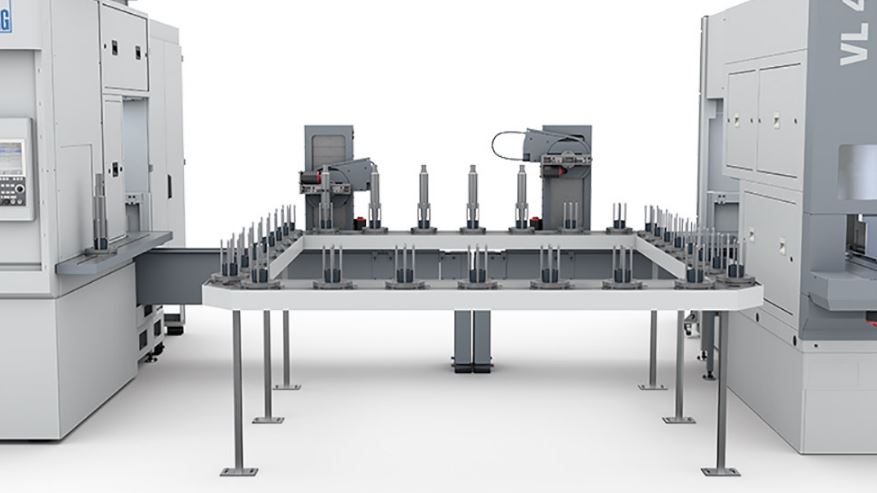

A continued rise in the demand for customized systems and integrated solutions was predicted back in 2014 by a survey of German manufacturers of plant and machinery, in a study on the future perspectives for the industry in Germany. This is not surprising given the huge “Industry 4.0” trend, as extensive automation in the form of customer-specific system solutions is a fundamental prerequisite for the digitalization of production facilities. The machines used then form an integrated system that production planners can control from a central point. Moreover, many companies need to respond ever more quickly and flexibly to technological developments. Numerous different versions of parts and fluctuating unit volumes are typical for small and medium-sized production companies in the automotive industry.

Today’s competitive talent marketplace requires small and medium contract manufacturers and OEM’s to make the most of the talent they have. Skilled, experienced machinists are hard to find and having them tied up hand-loading parts into a lathe is seldom the best use of talent. So – how does a successful small to mid-sized shop meet their customers’ production requirements with the existing talent pool?