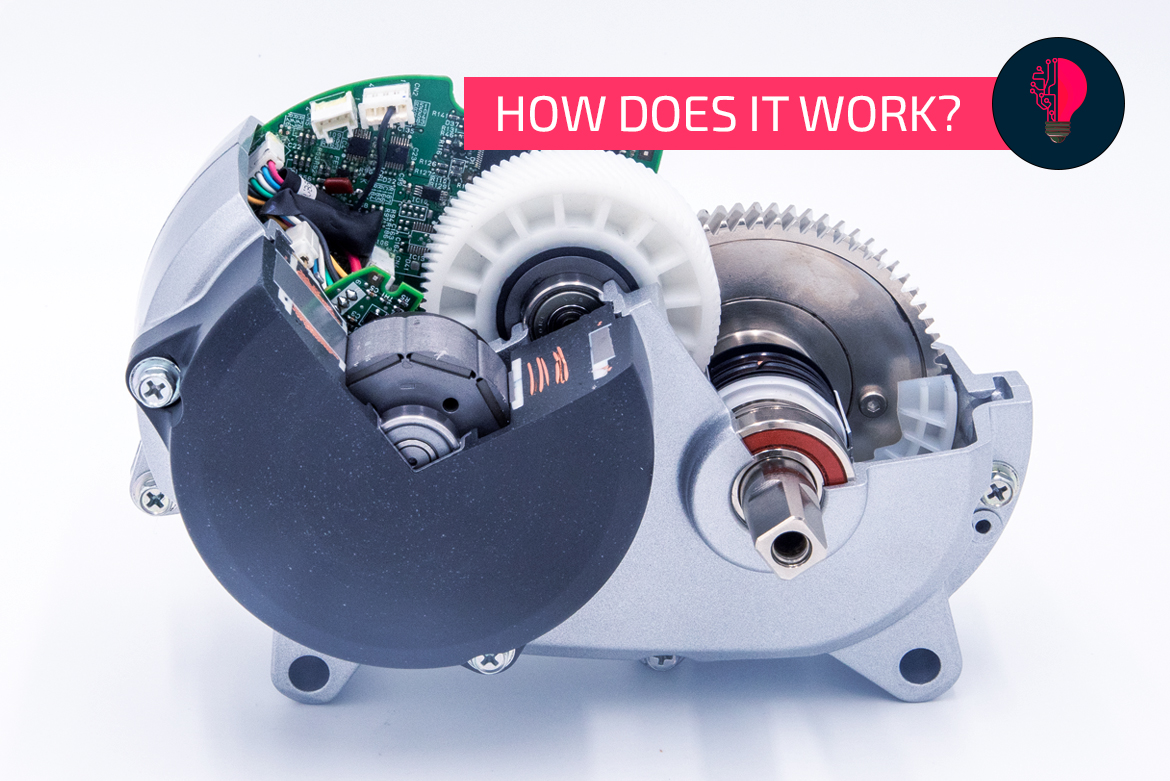

The e-bike market continues to boom – even if manufacturers have recently been unable to match the record figures from the pandemic. Nevertheless, around 1.6 million e-bikes were produced in Germany in 2023. In light of these large figures, it is particularly interesting to take a look at the central component: how exactly does the e-bike motor work, what characterizes its production and what changes are in store for the future?

Tag: