Actually, the turret inside a machine tool bears little resemblance to the barrel of a firearm in purely visual terms. So where does this name come from? We explain this in the following “How it works” blog. The same applies to the questions of how the whole thing works in detail and who invented it. Incidentally, the latter has a lot to do with the history of EMAG.

Turning

How can particularly large and heavy components be produced using lean production solutions? This question is becoming increasingly important, especially in the commercial vehicle sector, because price pressure in the market demands the lowest possible unit production costs. In this context, the VSC 500 and VSC 500 DUO machines from EMAG are real “game changers” for manufacturers. They load themselves and then ensure fast and precision complete-machining in a single setup or two. A conversation with Peter Gröner from the Turning Business Unit at EMAG about the enormous possibilities of this technology.

Find out more about the design and development of the VLC 350 GT turning/grinding center in our interview with Manfred Winkler, Head of Technical Sales, Business Unit Grinding. The VLC GT series from EMAG is one of the most successful new developments in recent years. The combination of proven pick-up automation, vertical machining and the ability to use various hard machining technologies in the spacious work area has made some great manufacturing solutions possible. We spoke to Manfred Winkler about the machine and the ideas behind the new development.

Large components and complex geometries—in heavy machining, this combination is far from being rare and always synonymous with a high expenditure of time and rising costs. The reason is that the various machining processes from turning to gear cutting are frequently performed in different machines that are not entirely interlinked with one another.

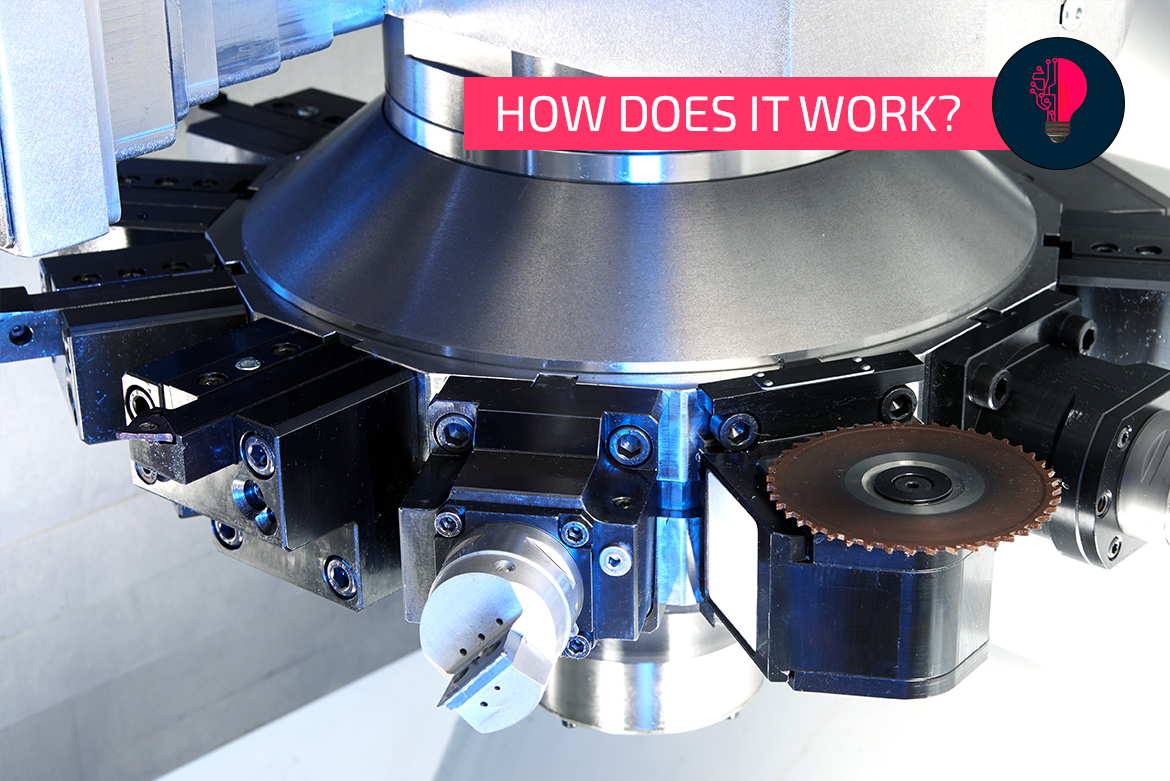

With its vertical turning/milling center VMC 450-5 MT, EMAG Leipzig breaks the vicious circle in an impressive manner: All turning, milling, drilling and gear cutting processes take place in a single machining area. To achieve this, the machine is equipped with five axes. This results in shorter throughput times and a minimal tooling effort—with increasing component quality and diversity.

The Swiss company Humbel has been involved in gear production since 1928—specializing in particularly sophisticated types of gears and transmission components, eventually evolving into a full-service supplier. At their facility in Kradorf, approx. 20 kilometers (12 miles) from St. Gallen, they produce both individual parts as well as complete assemblies. The company recently expanded their machine inventory to include a VL 4 vertical turning center by EMAG. — We spoke with Alex Humbel, Managing Director of Humbel Zahnräder AG in Kradolf, on the challenges facing gear producers, the importance of E-mobility, as well as their company strategy.

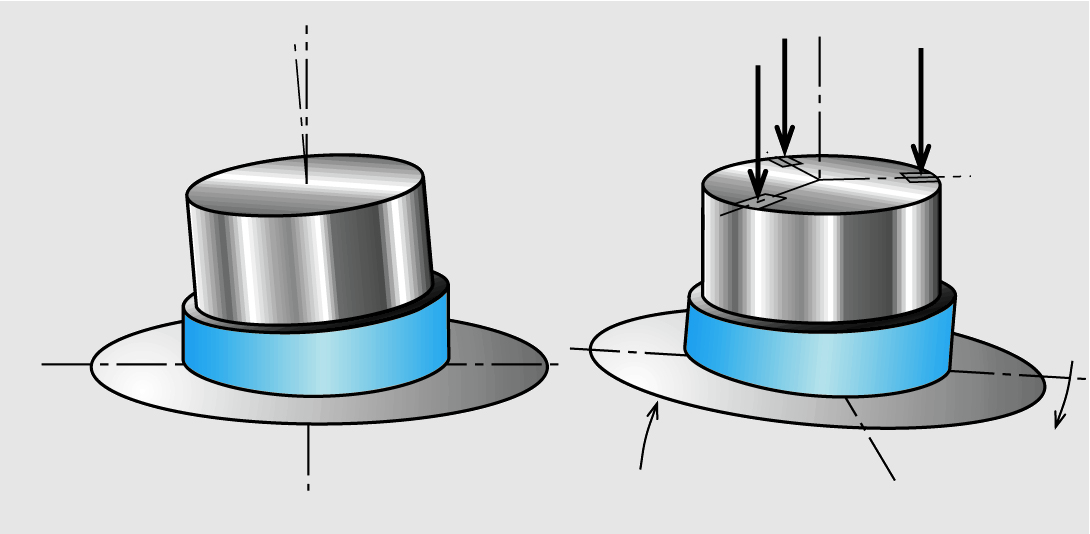

The EMAG Inverted Spindle Pick-Up Lathe process provides for a significant improvement in accuracy versus that of a sub-spindle lathe.

Lathes with sub-spindles pass a part from one rigid work holding system to another. This does not allow for any misalignment of the two spindles. The first spindle cannot release a part until the second spindle has a secure grip on it. Allowing for mismatches on a split turned dimension such as a bore. The accuracy and quality of the workpieces that are produced from this system are compromised because of this process.

The automotive world is constantly changing and improving. The industry strives to create vehicles with better fuel economy, while also increasing safety and reliability.

The introduction of hybrid and electric alternatives are becoming more popular, and in the years to come we will see these options continue to grow. With this change, certain components of today’s gas driven engines will be replaced with new components and technologies.

Today’s competitive talent marketplace requires small and medium contract manufacturers and OEM’s to make the most of the talent they have. Skilled, experienced machinists are hard to find and having them tied up hand-loading parts into a lathe is seldom the best use of talent. So – how does a successful small to mid-sized shop meet their customers’ production requirements with the existing talent pool?

EMAG’s Standard Modular Vertical Turning Solutions for chucked and shaft like components continue to gain market share within North America.

For years EMAG has continued to develop and invest in new technologies that make them the leading OEM of Manufacturing Systems for Precision Metal Components. We’ve become known world-wide for our Vertical Turning technology along with our ability to provide complete process chains to the world’s leading Automotive OEM. We’ve become the prominent leader in gear box, engines, and chassis solutions within the automotive industry but can also provide solutions within Energy, Aerospace, Agriculture, Construction and Oil Field.

Increasing cost pressure, high demands on part quality and frequent change of batches – the manufacturing of car brake discs is a difficult field. Particularly in the spare parts market, where users must request individual machining solutions that can be retooled for new workpieces without long downtimes.

- 1

- 2