Find out more about the design and development of the VLC 350 GT turning/grinding center in our interview with Manfred Winkler, Head of Technical Sales, Business Unit Grinding. The VLC GT series from EMAG is one of the most successful new developments in recent years. The combination of proven pick-up automation, vertical machining and the ability to use various hard machining technologies in the spacious work area has made some great manufacturing solutions possible. We spoke to Manfred Winkler about the machine and the ideas behind the new development.

Manfred Winkler, Head of Technical Sales, Business Unit Grinding

Mr. Winkler, what are the most important features of the VLC 350 GT?

The VLC 350 GT from EMAG is a versatile machine tool for workpieces up to a diameter of 350 mm. Its main features are the combined machining of hard turning and grinding, a large work area, fast pick-up automation, a 12-station turret and grinding spindles for internal and external grinding.

The VLC 350 GT from EMAG: A machine tool for combination machining, turning and grinding

Which applications suit this machine?

A typical application for the combined turning and grinding technology on the VLC 350 GT is the hard machining of chucked components, gear wheels of various designs, sprockets, pump rings and bearings. It offers high flexibility, productivity and quality – especially when machining pump rings. Pump rings play an important role in the manufacture of pumps, as they contribute significantly to the precision and efficiency of hydraulic systems. One specific application example is the radial piston pump, which is widely used for pumping lubricants in systems, machines and automatic transmissions.

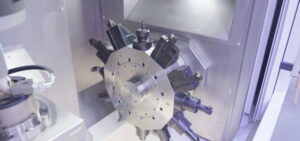

Turret of the VLC GT, a key element for the high flexibility and efficiency of the machine for different machining requirements

What advantages does the machine offer in terms of flexibility and productivity?

The large work area, the ease of set-up with large doors and easily accessible tools as well as the large number of selectable machining units make the VLC 350 GT very flexible. These features enable quick adaptation to different production requirements for both small and large series.

Interior view of the VLC GT: Example of the integration of turning and grinding technology in one machine

Where do you see the greatest advantages of combination technology?

The technology combination of turning and grinding on the VLC GT offers several advantages. By combining several processes on one machine, such as hard turning and grinding, considerable rationalization potential can be tapped. The advantages of complete-machining, quality and flexibility gains speak in favor of the process combination. The technology has proven itself in practice and is used very effectively to reduce cycle times. If the complete hard finishing process is carried out on one machine, lead times as well as transport and idle times can be drastically reduced. There are also advantages in the reduction of set-up processes and set-up times.

The VLC 350 GT with grinding spindles for internal and external grinding

What makes the VLC 350 GT unique in terms of its technological diversity?

The unique technological diversity of the VLC 350 GT lies in its ability to integrate a wide range of machining technologies such as hard and soft turning, out-of-round grinding, drilling, reaming, milling and honing. This diversity enables the efficient machining of a wide range of workpieces of different sizes and complexity.