Admittedly, the future of the manual gearbox is uncertain given the success of e-mobility and many automatic models. However, millions of cars are still equipped with this solution. What distinguishes the technology in detail?

1. How does the basic principle work?

Interrupting the power flow of the drive with the clutch, then changing gear and releasing the clutch – we carry out this process in the car almost unconsciously. It is indispensable because the narrow speed ranges of combustion engines are not sufficient for normal driving. In other words, without a manual gearbox, the engine could only reach medium speeds even at maximum revs. The transmission therefore translates engine speed and torque “into slow” at low speeds and “into fast” at higher speeds.

Most cars have a so-called manual transmission for this purpose. Here, the power of the engine is first transmitted constantly via a gearwheel to a countershaft, which in turn transmits the energy to the output shaft. The decisive factor here is that all gears of the countershaft and output shaft are always (!) connected to each other. However, only one of the gears on the output shaft is firmly connected to the shaft; the others turn freely on the shaft. To make this possible, there are the eponymous shift sleeves, which are operated via the shift lever. With their help, it is possible to determine which of the gears establishes the frictional connection. For this purpose, the couplings have internal teeth that can be pushed over externally toothed couplings on the shafts. As soon as the couplings have taken up their position, the driver can release the clutch.

Simple manual gearbox (manual sleeve gearbox) in the animation.

Source: Jahobr, CC0, via Wikimedia Commons; https://commons.wikimedia.org/wiki/File:Gearbox_4gears.gif

2. Why a manual transmission at all?

In principle, different ratios can also be produced by shifting the gears on the output shaft. This is referred to as a sliding gear transmission. However, these have a system-related disadvantage: it is generally quite difficult to slide from one gears to another. The sliding gear mechanism is therefore only used in today’s cars when reverse gear is engaged – with greater effort due to the special mechanical engineers. Incidentally, many racing cars use sliding-wheel transmissions because they are very resilient and can transmit higher maximum torques.

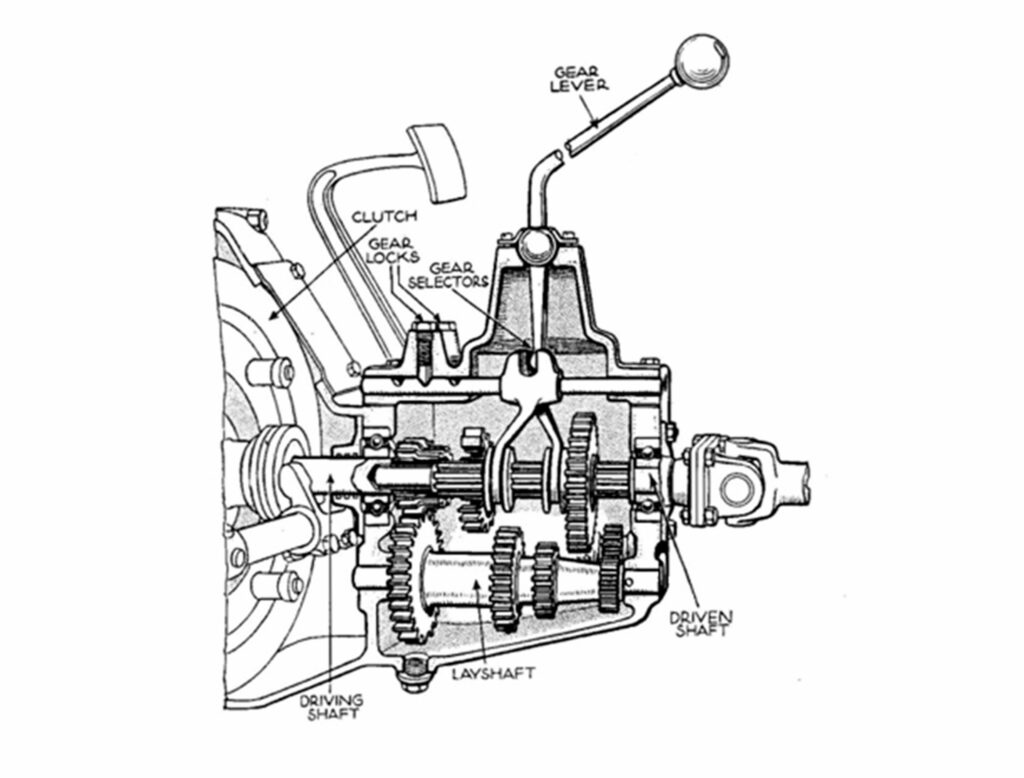

View of a manual gearbox including the various transmission shafts.

3. Who invented it?

The first manual gearbox was used as early as 1887 in Karl Benz’s invention. However, it was based on a leather belt that could be shifted to different pulleys using a gearshift to change the transmission ratio. The invention of Louis Renault, who developed the first three-speed gearbox near Paris at the turn of the century, is much closer to our idea of a gearbox. He completely dispensed with power transmission by chains (as was common at the time), instead relying on rigid shafts with gears. The invention was quickly copied by others and became the standard.

Illustration of a historic passenger car gearbox from the 1930s.

Source: Andy Dingley (scanner), Public domain, via Wikimedia Commons; https://upload.wikimedia.org/wikipedia/commons/0/04/Gearbox_%28Autocar_Handbook%2C_13th_ed%2C_1935%29.jpg

4. What does the future hold?

For many experts, the days of the manual gearbox are numbered. There are a number of indications of this. On the one hand, some major manufacturers are only launching the next generation of their models with automatic transmissions. On the other hand, the registration statistics speak for themselves. For example, the proportion of vehicles with manual transmissions among new registrations in Germany in 2000 was still around 80 percent. Today it is only 40 percent. The power of the engine plays a role here: the more horsepower, the more likely an automatic transmission is to be used. The trend towards electromobility is also a turning point: most e-cars now only have a single-speed gearbox, which reduces the engine speed. There is no longer a shifting process while driving.

5. What are the advantages and disadvantages?

Manual transmissions are more compact and lighter than automatic transmissions – and last but not least, they are also cheaper. A price difference of at least around 2,000 euros between the two variants is the rule. The disadvantages are obvious: manual shifting is less comfortable, there is a greater interruption in tractive force during shifting and we’ve probably all experienced a “gear shift” at some point…

1 comment

love the gear box illustration. fantastic!