“Smart technologies drive tomorrow’s production!” That is the motto for EMO 2019 in Hanover, Germany. But we believe that smart people, and not just smart technologies, are what matters—and we need to bring those people together to talk.

So, at the EMAG Group’s booth, we will be focusing not just on networked technologies, but also on networking with our visitors.

To give you a preview of who you really should talk to at the EMO, over the next few weeks we will be publishing regular interviews with the EMAG experts who will be there in person.

Interview with Sebastian Sieland, EMAG Leipzig

Mr. Sieland, can you tell us a little bit about what you do?

I am in charge of worldwide sales at EMAG Leipzig. I centrally manage all sales activities, from America to Asia, for our VMC series and oilfield machines.

What does EMAG Leipzig do within the EMAG Group?

EMAG Leipzig Maschinenfabrik GmbH has been part of the EMAG Group for exactly 20 years. We develop coupling and pipe machining systems for the oilfield industry as well as automated vertical multi-technology machines.

What will you be presenting at the EMO?

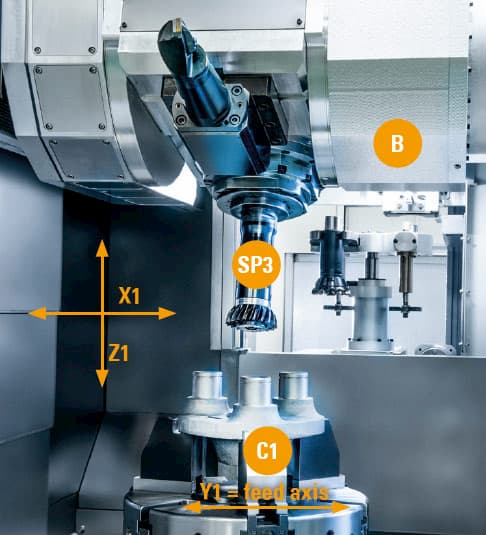

At the EMO, we will be presenting the VMC 450-5 MT, our multi-technology turning/milling machine. This high-precision 5-axis turning/milling machine is an impressive solution for machining large and complex workpieces in a single clamping operation. But we also want to show our visitors the VMC 450-4, which even further increases productivity with its 4-axis machining capability.

Another highlight we will be presenting at the EMO is the combination of 3D component printing with our partner Gefertec and the finishing of those components on our VMC machines.

Who specifically is your machine aimed at?

Our customers come from the commercial vehicle and supplier industry as well as the railway industry. Possible applications for the VMC 450-5 MT are numerous, as many large components in utility vehicles and industrial transmissions, in shipbuilding and railway construction, as well as in the agricultural and mining sectors are unusually complex. With the VMC 450-5 MT, all turning, milling, drilling and gear cutting processes can be carried out in a single machining area. To achieve this, the machine is equipped with five axes. The VMC series brings new flexibility to the machining of large commercial vehicle components such as truck wheel hubs and planetary carriers, clutches, and brake components.

Tell us in a nutshell why we should visit the EMAG Group’s booth at the EMO?

With its broad technological basis and extensive machine portfolio, EMAG offers the perfect palette of tools for development of tailored production solutions. We will be focusing in particular on subjects such as electromobility, intelligent automation solutions, industry 4.0 and digitalization of production, and have plenty of information to share with our visitors.

Thank you for this interview!