The future is “under power”: electric motors will be used in many places in the future – from cars to heating systems – in order to avoid the consumption of fossil fuels. The basic principle of a conventional electric motor is always the same: magnetic fields drive a shafts. How exactly does it work?1. What characterizes the drive?

The basic idea is amazingly simple and is based on the principle of electromagnetism: when current flows through a conductor, a circular magnetic field forms around it. The designers of electric motors make use of this effect. Inside them, there is a fixed component (stator) in which there is a moving magnetic component (rotor). The current now flows through the individual stator segments and the magnetic field mentioned is created, whereby its orientation depends on the direction of the current – and this means that the polarity of the fields can be reversed at a rapid rhythm so that the (equally magnetic) rotor remains in continuous motion. Of course, there are various versions of this approach – for example, with regard to the question of whether direct current, alternating current or three-phase current is used.

Animation of a simple DC motor.

Source: https://de.wikipedia.org/wiki/Gleichstrommaschine, MichaelFrey, CC BY-SA 3.0 , https://creativecommons.org/licenses/by-sa/3.0, via Wikimedia Commons

2. Who invented it?

This is not easy to answer, as the use of electricity in a fully functional motor is at the end of a whole chain of innovations. One milestone was the discovery of electromagnetic rotation by Michael Faraday in 1821. In an experiment, he succeeded in setting a conductor through which current was flowing in motion under the influence of a permanent magnet. Various scientists subsequently developed various electric motor precursors. The first practical model can be traced back to the German-Russian physicist Moritz Hermann von Jacobi. His motor propelled an electric boat on the Neva in St. Petersburg on September 13, 1838. It initially only travelled at a speed of 2.5 kilometers per hour, covering a distance of 7.5 kilometers. The physicist later increased his motor to an output of 4 kilometers per hour.

3. Are there any special features of the e-car?

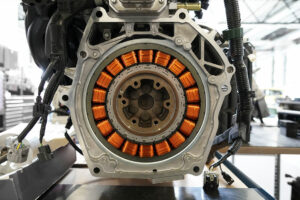

First of all, it is important to note that AC motors are primarily used in electric cars because the DC version is less efficient and has a lower power density. A distinction is also made in cars between asynchronous and synchronous motors. In the former, the rotor, which is magnetized by induction, is located in the magnetic field of the stator. The rotor magnetic field lags behind the stator magnetic field. The two are therefore not synchronous. Hence the name of this motor variant, which has two major advantages. Firstly, its design is relatively simple, and secondly, it can simply be de-energized and then moved without resistance.

In contrast, the magnetic fields of the rotor and stator always move in sync with each other in a synchronous motor. This principle is also used in electric cars, although it is more efficient than the asynchronous variant. However, some manufacturers use permanent magnets in the rotor, including rare earths, which increases costs. However, there are also synchronous motors without permanent magnets.

View of the stator in an open electric motor.

4. What does the future hold?

It is obvious that e-mobility is the future in many different areas – think of trains or ships, for example. The question of whether it will also be possible to power aircraft with electricity in the future is particularly interesting. Various universities are researching this issue. One thing is certain: aircraft engines are nothing more than very fast and powerful fans that could be powered electrically. However, the motors required for this are currently still very large. Researchers are therefore working on a new generation of e-drives that are much smaller.

5. What is important in automotive production?

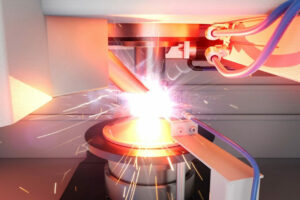

Of course, the central components such as the rotor, stator or motor housing require extreme precision – this is nothing new for the automotive sector. What’s more, quantities are increasing massively. Production planners are therefore looking for innovative solutions “from a single source” with which the components can be machined particularly efficiently and reliably. EMAG demonstrates what this means for so-called “assembled” rotor shafts with the ELC machine.

Assembled rotor shafts also undergo a welding process in which the two halves of the component are joined together.

In this integrated technology, joining, cleaning and welding processes are compactly combined on an assembled rotor shaft.