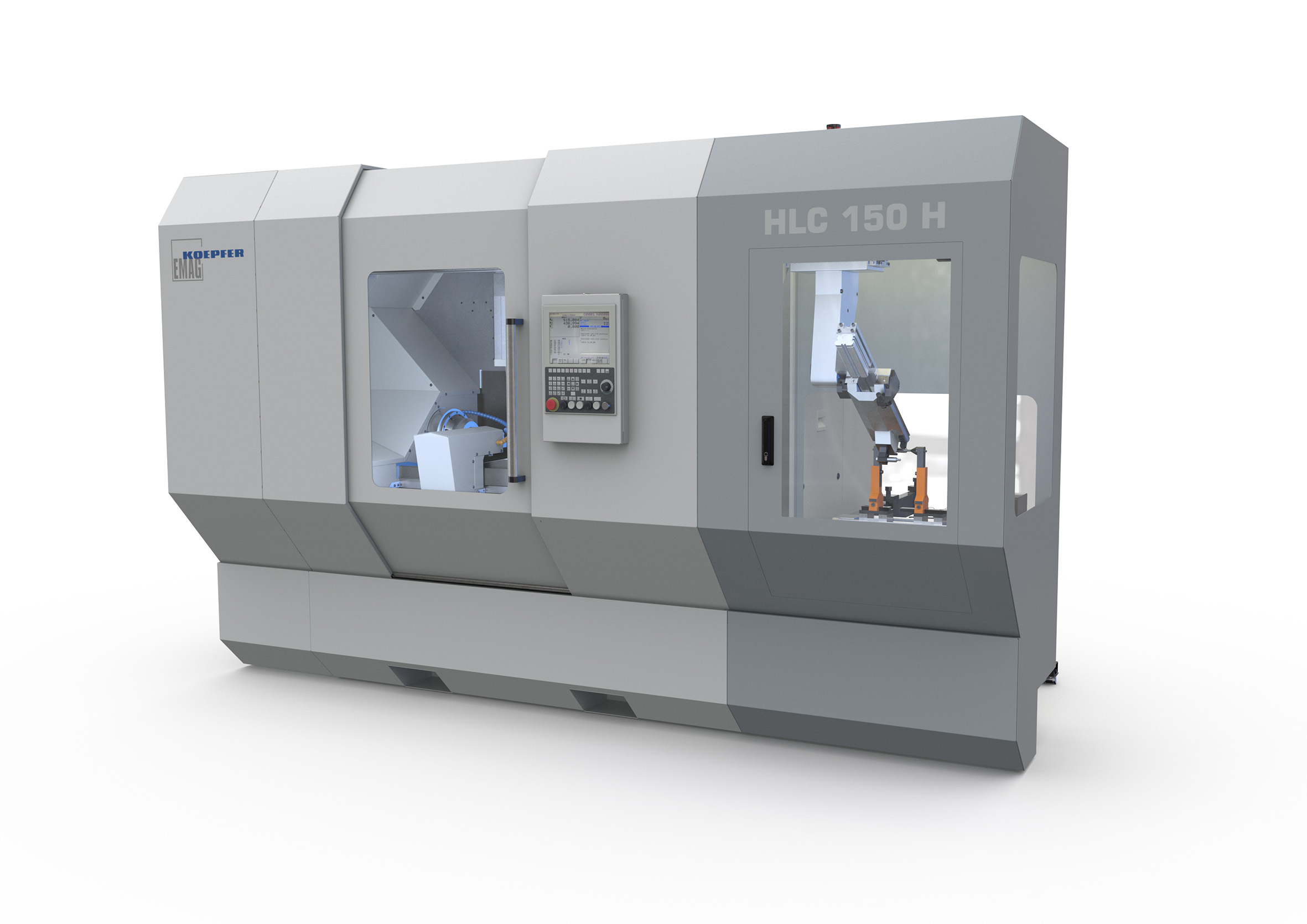

Maximum flexibility is required for gear production. EPS steering is a good example: Production planners for this application are looking for machines that can efficiently and completely cut an EPS steering gear including steering pinion, worm gears, and screws. The HLC 150 H horizontal gear cutting machine from EMAG KOEPFER is the perfect solution for this.

Gear cutting and deburring

The gear-cutting specialists have developed a complete solution that covers every aspect of the process: It features all relevant gear cutting technologies including chamfering. Components with toothing up to module 3 and up to 500 millimeters in length can be completely finished. For a transmission shaft, for example, gear hobbing for rough-machining is the first step, followed by press deburring, and a second hobbing step for finishing.

The HLC 150 H horizontal gear cutting machine from EMAG KOEPFER is the perfect solution for complete gear cutting.

High-quality gear cutting guaranteed

With this machine, customers also benefit from many upgraded technical details. For example, the large axis center distance of up to 130 millimeters, and the powerful 28 kW cutter head ensure flexibility and efficiency. During the milling operation, the cutter head, with its very rigid suspension, always moves completely. This guarantees that the hobbing process is always very smooth and precise. Decreasing unit costs are also ensured by energy-efficient hydraulic units. Furthermore, the quick-clamping system makes it possible to change tools very quickly, minimizing unproductive downtime’s.

For more information please click here…