The forces in a transmission are not always transmitted with the help of gears. There are exceptions, such as the CVT transmission, in which a steel belt or a multi-plate chain moves on conical pulleys. We explain exactly how this works here. There is also some interesting information about this invention, which dates back to the 19th century.

1. How is power transmitted here?

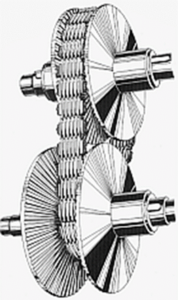

The name already hints at the decisive quality of this technology: CVT stands for “Continously Variable Transmission.” That means that this transmission solution always keeps the engine in the ideal speed range. This is made possible by an amazing idea: the drive and output axles are connected by a steel band (or chain) that is guided over opposing conical pulleys on both axles. Because these pulleys can be moved, the rotation radius for the belt and the transmission ratio between the axles varies.

If the disks move apart, the belt moves inwards. In this case, the radius of the taper is smaller. If the discs are pushed together in the axial direction, the belt is located on the outer edge of the cone shape and, therefore, covers a larger radius.

This gearbox solution always keeps the engine in the ideal speed range.

Source: https://de.wikipedia.org/wiki/Variomatic, W.Rebel, CC BY 3.0, https://creativecommons.org/licenses/by/3.0, via Wikimedia Commons

2. Who invented it?

The story of the CVT transmission begins in a sawmill in the USA at the end of the 19th century. This is where the future engineering genius Milton Reeves worked as a teenager and recognized a problem: the cutting speed of the saw blades could not be controlled because the drive only allowed one speed. As a result, he developed the first CVT gearbox, which was soon used in various machines.

Many years later, the car manufacturer DAF in Eindhoven achieved a significant innovation. In 1958, the DAF 44 appeared with a continuously variable CVT automatic transmission under the name “Variomatic.” It changes its transmission ratio automatically, using a V-belt. Interesting fact: the car can drive backwards as fast as forwards and was used in reverse races in Holland…

The system requires little space and works efficiently.

Source: https://de.wikipedia.org/wiki/Variomatic, Büdeler Naumann, CC BY-SA 3.0, http://creativecommons.org/licenses/by-sa/3.0/, via Wikimedia Commons

3. Where is the CVT transmission being used successfully today?

Overall, continuously variable transmissions have become less common because dual-clutch transmissions and torque converters work just as efficiently without interrupting traction. However, some manufacturers are still sticking with the technology, and interestingly enough, this also applies to hybrid engines, because on the one hand CVT transmissions require relatively little installation space and on the other hand they ensure an optimized drive under all driving conditions. In other words, even if the battery is empty, you can still start off with the usual high-performance. Incidentally, many CVT hybrids score with low energy losses, which in turn increases the purely electric range of the hybrids.

4. Are there any disadvantages?

A chain that runs over moving pulleys – with this in mind, it is obvious that the central components of a CVT transmission are subject to heavy loads. Over the years, the chain can wear out or the conical pulleys are no longer in the correct position. One consequence of these weaknesses is that more frequent oil changes are necessary in CVT transmissions than in other designs. Apart from these technical disadvantages, many drivers are “alienated” by the technology because the background noise is unfamiliar as the engine speed remains constant even when accelerating.

5. What are the challenges in production?

The pulleys in particular must be manufactured with high precision and without any deviations, as their surface quality influences the functionality of the entire gearbox. In addition, production planners do not accept any machining errors, especially in hard machining, because the costs for each hardened blank are quite high. Consequently, several turning and grinding machines are usually used for this purpose, which are perfectly automated and also connected to a central master computer. Multi-stage measuring systems are just as much a part of this as a laser system at the beginning, which provides each component with a DataMatrix code and thus guarantees 100% traceability in the production process.

The pulleys in CVT transmissions must be manufactured with high precision.