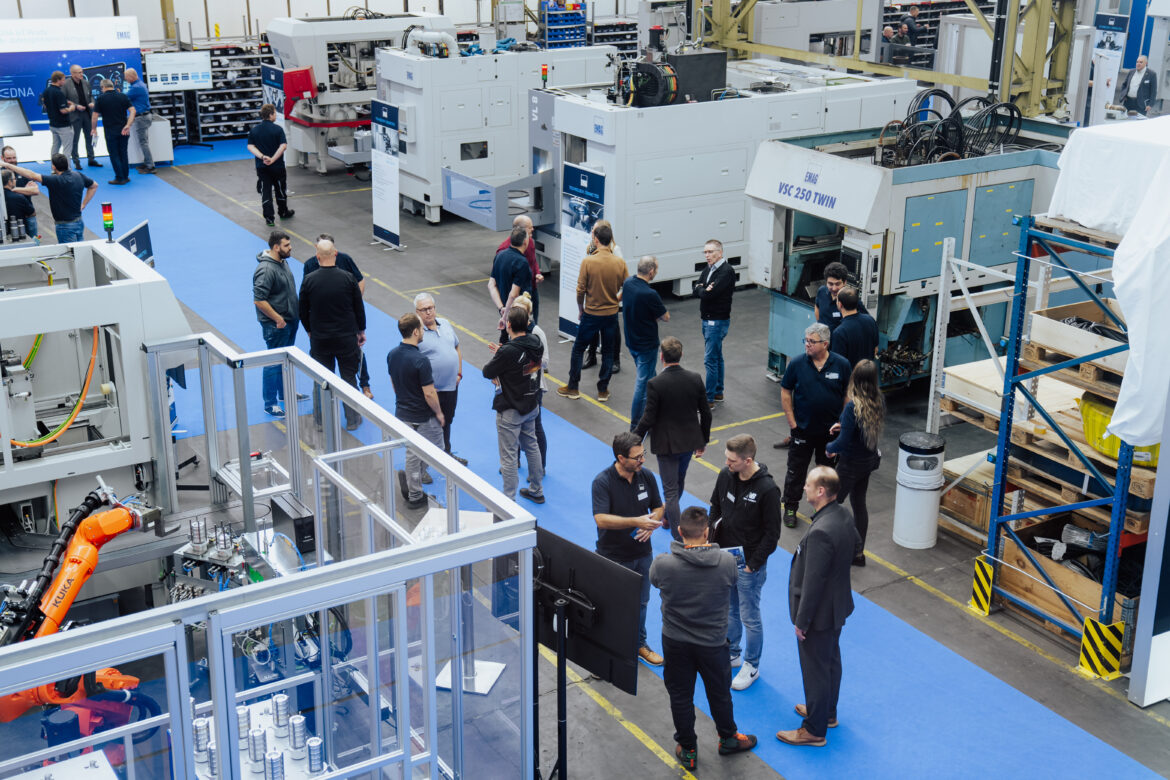

During the Open House Retrofit at the Eislingen plant, EMAG presented the future of industrial machine modernization. Visitors had the opportunity to experience the latest technologies and retrofit solutions at first hand.

Presentation of a fully automated retrofit manufacturing system

One highlight was the demonstration of the VSC production system, which is equipped with the Sinumeric One control system, an integrated robot cell and a DMC read/write system. The participants were able to experience this production system live in action and see for themselves the possibilities of retrofitting far beyond machine modernization.

Innovative VSC production systems in use

Live demonstrations and individual guided tours

During the event, experts from EMAG gave live demonstrations of the various retrofit options. In addition, personal tours were offered, giving visitors an insight into the practical implementation of retrofit processes at the plant.

Flexibility and diversity in the retrofit approach

EMAG’s retrofit concept is extremely flexible. It ranges from minor adjustments to the complete mechanical and electrical rebuild of the machines. It is interesting to note that the process does not always begin with the overhaul of an old machine. Customers often come to EMAG with specific components and place new production requirements on the machines. EMAG’s experts then develop a customized retrofit solution based on the customer’s machinery and adapt the production processes.

Sustainability & digitalization

Two key topics at the event were sustainability and digitalization. EMAG emphasized the importance of future-proofing when modernizing production solutions. With IoT expertise, the company equips machines with industrial PCs and sensors to increase machine productivity with intelligent software solutions.

Digitalization meets mechanics: EMAG integrates state-of-the-art industrial PCs and sensor technology into retrofit machines.

In the area of sustainability, EMAG offers to analyze existing production solutions in order to identify energy wasters and implement more efficient processes. For example, after a retrofit, the machine’s media and drives can be switched off automatically if no machining program is running.

Sustainability in practice: EMAG shows how retrofitting increases energy efficiency and environmental awareness.

The Open House Retrofit at EMAG was not only a demonstration of the latest machine technology, but also an insight into the company’s forward-looking approaches to sustainability and digitalization. The event showed that the costs for retrofit solutions quickly pay for themselves, especially with the current high energy and material costs.