“Customized” is the key word when it comes to delivering a perfect production solution for building systems and machinery. Each technology is individually tailored to the customer’s environment, guaranteeing a highly efficient and optimally configured process. Induction heating in particular is one of the technologies that requires customization because the quality of the customer’s process depends on a whole range of very specific details. As the energy source, the generator plays an important role here. The experts at EMAG subsidiary eldec, based in Dornstetten, Germany, know this very well.

30 years of experience in generator construction

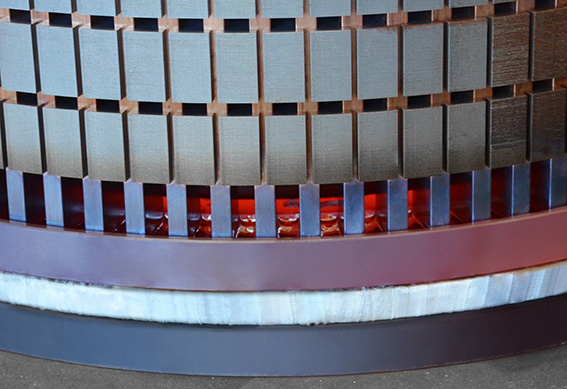

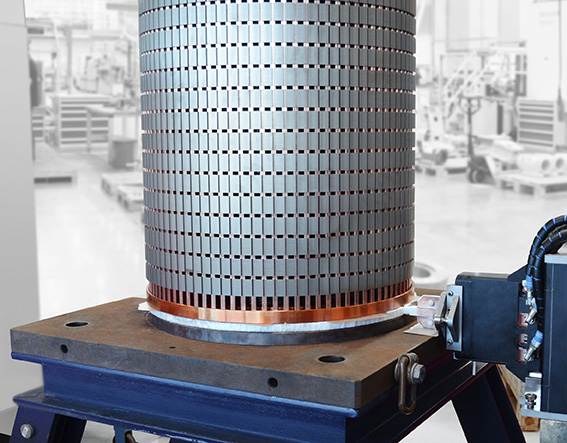

For more than 30 years, engineers at eldec have been developing a wide variety of generators, including many customized models in the CUSTOM LINE. The design goal — all the resonant circuit components in conjunction with the control architecture should form a precisely tailored product, which provides induction heating with high efficiency, controlled application of energy and stable processes. Close collaboration with customers, therefore, plays a key role over the entire development process of the generator.

Custom energy sources with eldec’s CUSTOM LINE generators

In addition to the standardized models in the PICO, MICO, and ECO ranges, eldec also offers CUSTOM LINE solutions.

The resonant circuit, the inverter and the inverter control are always adapted to match the inductor, the required frequency and the power output. This also applies to the more standardized series, which are able to cover about 80 percent of the current application spectrum.

With the CUSTOM LINE, however, virtually all the components can be configured in a fully variable way — from general device control to the outputs and interfaces.

Almost infinite number of possible variations

Just how far this approach goes can be seen by looking at the details of the configuration. Take the outputs, for example. eldec engineers are not only able to equip their technology with single or multiple outputs, but also to distribute the generator’s output power with complete flexibility. It can be made available in parallel for independent control or it can be supplied in an “either-or” arrangement, so that it is available only at one of the outputs at a time. What are the advantages of multiple outputs for the user?

Benefits of CUSTOM LINE generators

One benefit is that several areas of the part can be heated at the same time to speed up the cycle. In addition, a variety of inductors can be connected to just one generator and operated in sequence. This reduces purchasing costs for heating equipment if the cycle time is of secondary importance.

At the same time, eldec is always able to modify the power and frequency features of its devices in virtually unlimited ways to adapt the process to the customer’s needs. The scope ranges from medium-frequency generators with a power output of 20 to 1,500 kW and a frequency range of 8 to 40 kHz, up to high-frequency generators with 20 to 1,500 kW output and frequency ranges from 80 to 400 kHz. A multitude of combinations are possible. The decision ultimately depends on the workpiece or the geometry that needs to be heated. As a result, the actual values may be even higher or lower than those described above.

Perfectly positioned

With its highly customizable portfolio of generators, eldec considers itself in an ideal overall market position. eldec has an enormous amount of expertise at its disposal, continually develops its technology and delivers only optimally configured and robust components. In addition, eldec’s high level of vertical integration gives the company the advantages of high responsiveness and versatility.

Please see here for more information about CUSTOM LINE generators.