Machining of covers for 155 mm artillery shells with EMAG VL 4

Manufacturing components for artillery shells requires precision, efficiency and a sound technical understanding of the entire production process. As a leading supplier of manufacturing systems for the defense industry, we offer tailor-made solutions for machining covers for 155 mm artillery shells with our high-precision VL 4 machines.

Specialized production solutions with VL 4 machines for the highest quality requirements

Process-optimized manufacturing solutions for the defence industry

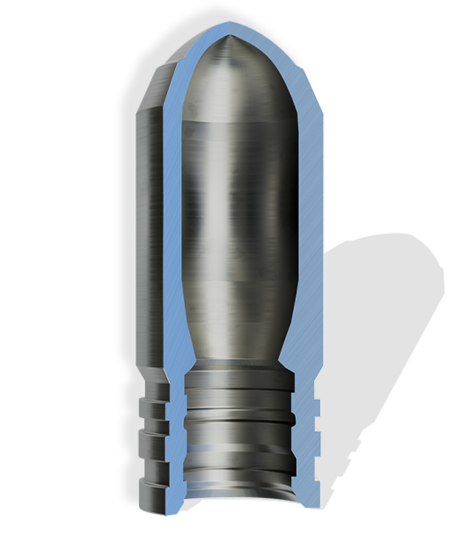

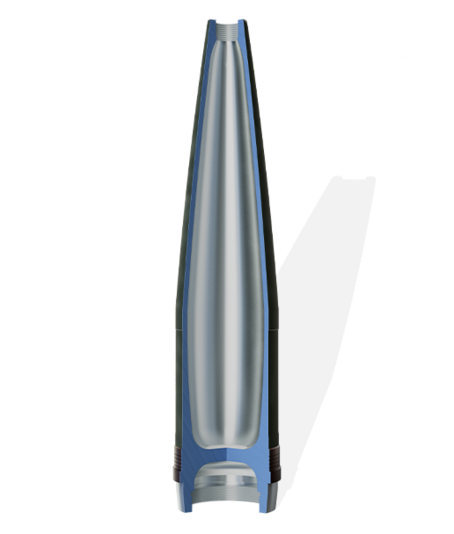

The cover is a critical component of the 155 mm artillery projectile and requires precision manufacturing to ensure the ballistic performance and reliability of the overall system. Our VL 4 vertical lathes have been specially designed for this demanding task, enabling highly efficient machining in four consecutive operations with minimal set-up times.

Technical specifications of the VL 4 machine for cover machiningThe VL 4 vertical turning machine offers the following advantages for machining cover components in the defense industry:

|

Process for cover machining on VL 4 machines

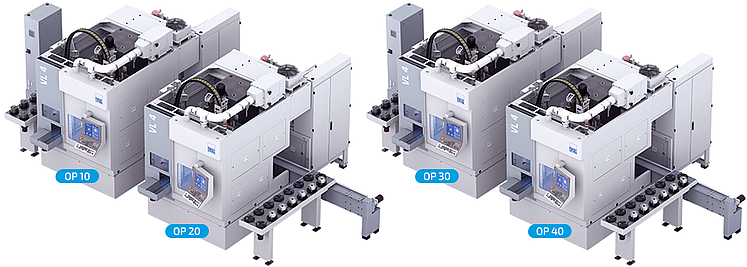

The production process for the 155 mm artillery shell cover is divided into four operations (OP10-OP40).

Automated production lines for maximum efficiency

EMAG offers individually tailored automation solutions such as TrackMotion systems, which have been specially optimized for the requirements of the defence industry. These enable continuous, highly automated machining of covers for 155 mm artillery shells, reduce production costs and significantly improve process quality.

Advantages of cover machining with EMAG VL 4 at a glance:

- Fully automated vertical pick-up machining

- High process reliability thanks to minimal manual intervention

- Flexible complete-machining in a single setup

- Optimized tool life and reduced non-productive times

- Customized automation solutions for variable batches

(1) macchine trovate

Tecnologie

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…