14/11/2025 - Oliver Hagenlocher - Press

VSC 500 and VSC 500 DUO: Perfecting turning processes on large and heavy truck components

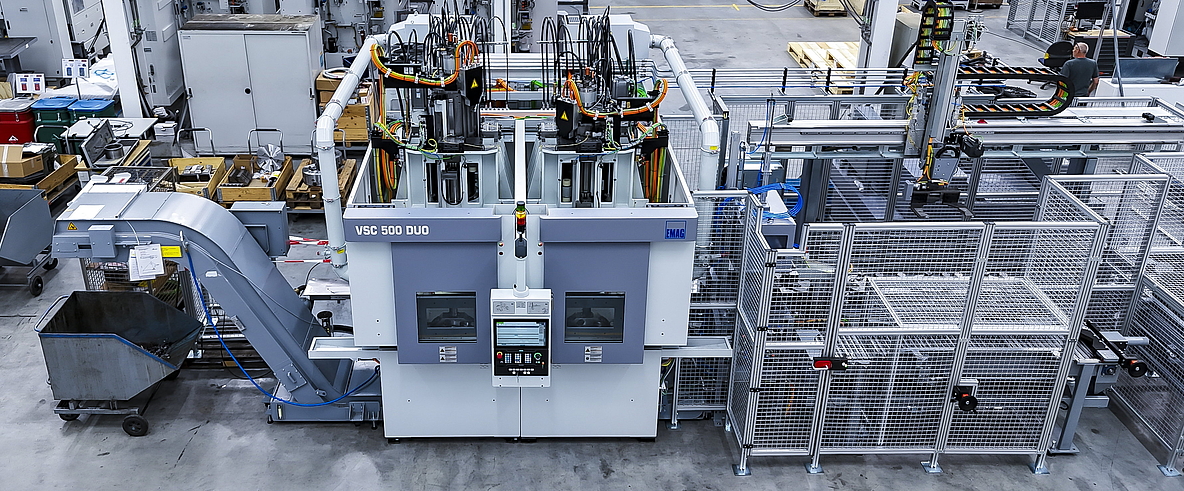

The commercial vehicle market is facing major changes: Battery electric and hydrogen drives are set to take over in a few years and partially replace the classic combustion engine, according to politicians. However, the necessary models first have to be produced in large numbers. In view of this, planners are focusing on commercial vehicle production. They are looking for efficient and lean production solutions for relatively heavy components. The EMAG Group is demonstrating what these can look like with a new edition of the successful VSC 500 and VSC 500 DUO pick-up machines: They load themselves and then ensure complete-machining in a single setup or two. Their design also ensures speed, precision and process reliability. What is important in detail and what are the innovations?

Immagini

Whether wheel hubs, couplings, bevel gears or brake discs - the large and heavy components used in commercial vehicle production pose a particular challenge. Manual loading of horizontal lathes, for example, is very time-consuming, the solutions take up a lot of space and the establishment of gantry loaders generates high capital investments. In this context, the VSC series from EMAG has scored particularly well for years, as the work area is loaded and unloaded simply by means of an integrated pick-up spindle. Many different processes can then be carried out in a single setup, while integrated measurements ensure process reliability. For workpieces with a maximum diameter of 440 millimetres and a maximum length of 250 millimetres, the VSC 500 is the measure of all things, although the machine is also used outside the commercial vehicle market. Its enormous spindle power of 80 kilowatts (at 40 % ED) and 1,100 Newton meters is a decisive technological quality. A spindle with 92 kilowatts (at 40 % ED) and 2,530 Newton meters is also available for even higher chip capacities.

Mechanical engineering quality for greater precision

The actual quality of this technology is revealed when looking at the typical elements of EMAG machine construction: For example, the basic body is made of Mineralit®, which has 8 times better damping compared to cast iron, which in turn leads directly to longer tool life. "In addition, there is a hydrostatic guide principle in the Z-axis," explains Peter Gröner from the Turning Business Unit at EMAG. "The guide cylinder moves in an oil film, which provides more stability during hard machining, for example." The symmetrical design of the machine is similarly effective. This ensures a closed flow of force and reduces thermal influences. "Ultimately, users benefit from a process with high continuous accuracy because the cutting forces flow in symmetrically," summarizes Gröner. The turret also ensures maximum flexibility, as it can hold up to twelve tools, whereby each position can also be equipped with a driven tool holder. As a result, it is no problem to combine different turning processes with drilling processes, for example. This is a decisive advantage, especially for large-volume production, as Peter Gröner explains. "The component can be produced in a much shorter time with reduced handling effort. The individual steps run directly one after the other in a matter of seconds."

Anyone asking about components that have to undergo various machining operations will be presented with a whole range of options by EMAG. One of these is the VSC 500 DUO machine already mentioned at . It has two work areas with separate machining areas, which prevents the transmission of vibrations during the process. As a result, it is possible, for example, to machine a component in two separate setups from two sides (OP 10 and OP 20). Between the setups, the component is turned with a turning device during idle time. It is also possible to finish two identical components in parallel in one setup, for example to increase the output quantity. Furthermore, all VSC machines can be combined very easily to form complex production lines, as the pick-up technology provides an ideal basis for this: It takes over the "internal" loading of the work area in each case, which is why the line automation (for example via gantry loader or robot) only has to ensure the connection between these machines.

New generation scores with high accessibility

Finally, there is still the question of the new features of all VSC machines, as EMAG redesigned the entire series some time ago. "Overall, our main aim was to further increase accessibility to the machine and at the same time improve workplace safety," summarizes Peter Gröner. For example, the machine is open at the top when the front door is open, which makes access much easier. A maintenance platform, which can be easily mounted, makes it easy for service personnel to access the overhead slide. A bellows is similarly helpful as a supplementary cover for the headstock: it seals off the work area, especially during loading and unloading. "In this way, the machine is better sealed from the outside, which is of course noticeable in daily use," says Gröner. "Overall, customers benefit from productive and highly precise processes - and not just in commercial vehicle production. The machine is used wherever large and heavy components need to be machined with efficient production solutions."

Referenti

Oliver Hagenlocher

Zona

Press and Communication