The gear skiving process, also known as power skiving, is becoming increasingly popular with many users in the manufacture of gear components. This is no coincidence: compared to the shaping process, it is significantly faster and also offers more flexibility than hobbing and broaching. However, for a long time it was considered relatively complex. In this context, the VSC 400 PS represents a turning point – the application of power skiving is significantly simplified, as only minimal data is required from the operator, eliminating the need for extensive expertise in gear cutting. To take a closer look at the technology behind the VSC 400 PS and its impact on the industry, we interviewed Daniel Nille, Head of Technology Development for EMAG Power Skiving.

Oliver Hagenlocher

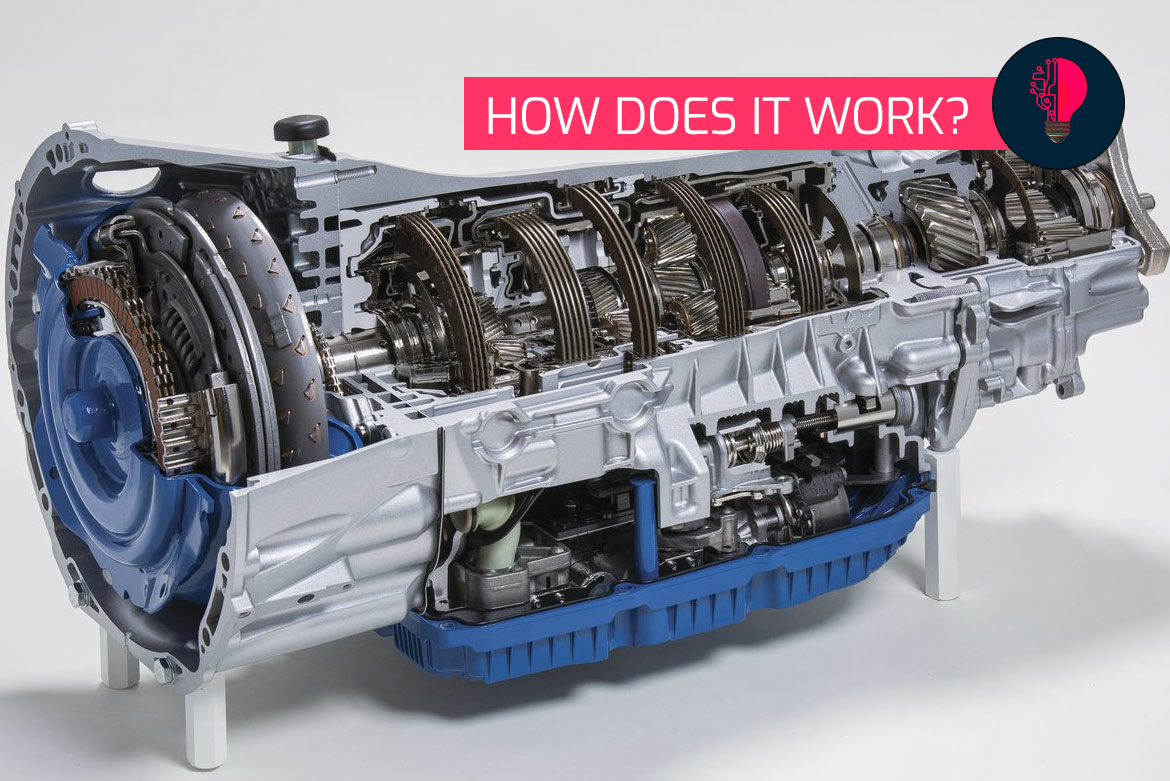

Planetary gears have been around for over 200 years – the first one was used in a steam engine at the beginning of the 19th century. The technology is still indispensable in cars, for example. What distinguishes the whole thing in detail and what are the differences in design?

For the past several years, EMAG has offered a turning machine for high-productivity turned parts production, the VL 3 DUO. We spoke to Björn Svatek, Director Global Sales, about the advantages and special features of this machine concept.

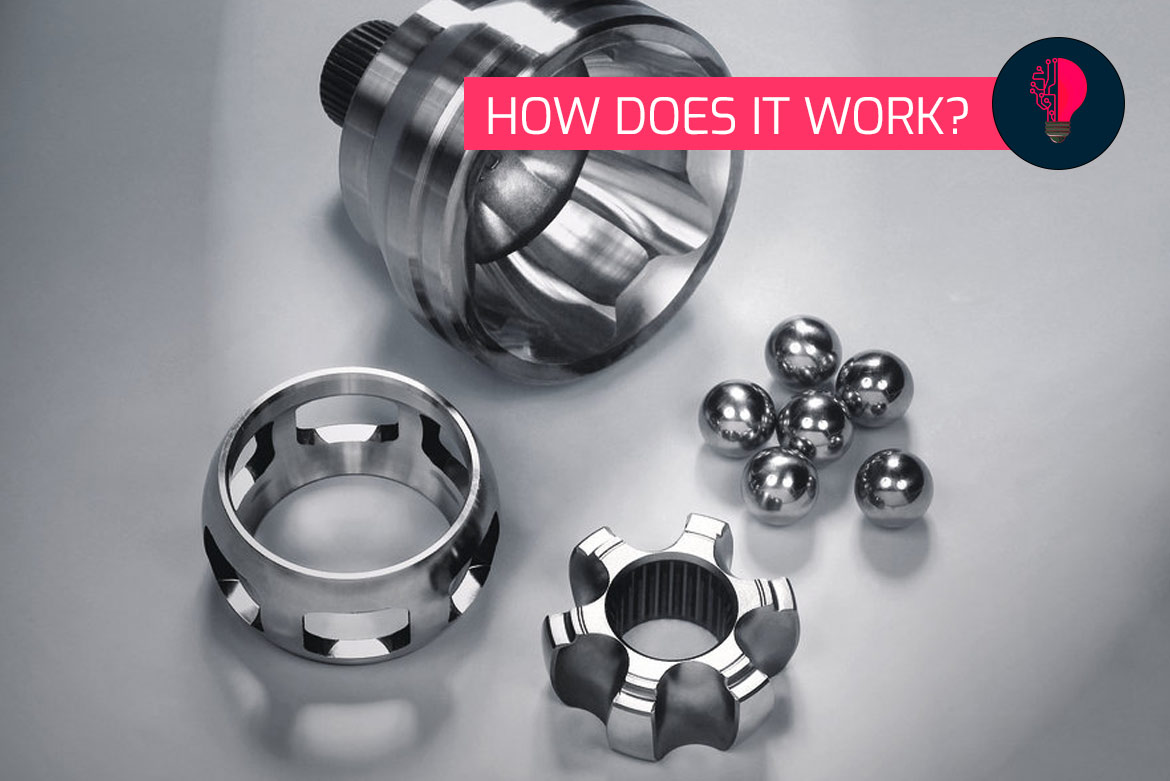

CV joints are indispensable, especially in vehicle construction. Their greatest strength: they transmit the rotational movement between two shafts completely uniformly. As a result, there is no “jerking” or similar, which would put unnecessary strain on all the components involved. We have compiled some fascinating information about this invention here.

The EMAG ELC 6 laser welding machine plays a key role in the production of drive components for electric motors. In our interview with Konrad Eibl, you will gain a deeper insight into how the ELC 6 works, the technical aspects and the wide range of possible applications. You will learn how this innovative machine contributes to increasing efficiency in production and what role it will play in the future of manufacturing technology. Particular attention will be paid to the production of rotor shafts, a critical element in the rapidly growing electromobility industry, where precision and process reliability are highly important.

Find out more about the design and development of the VLC 350 GT turning/grinding center in our interview with Manfred Winkler, Head of Technical Sales, Business Unit Grinding. The VLC GT series from EMAG is one of the most successful new developments in recent years. The combination of proven pick-up automation, vertical machining and the ability to use various hard machining technologies in the spacious work area has made some great manufacturing solutions possible. We spoke to Manfred Winkler about the machine and the ideas behind the new development.

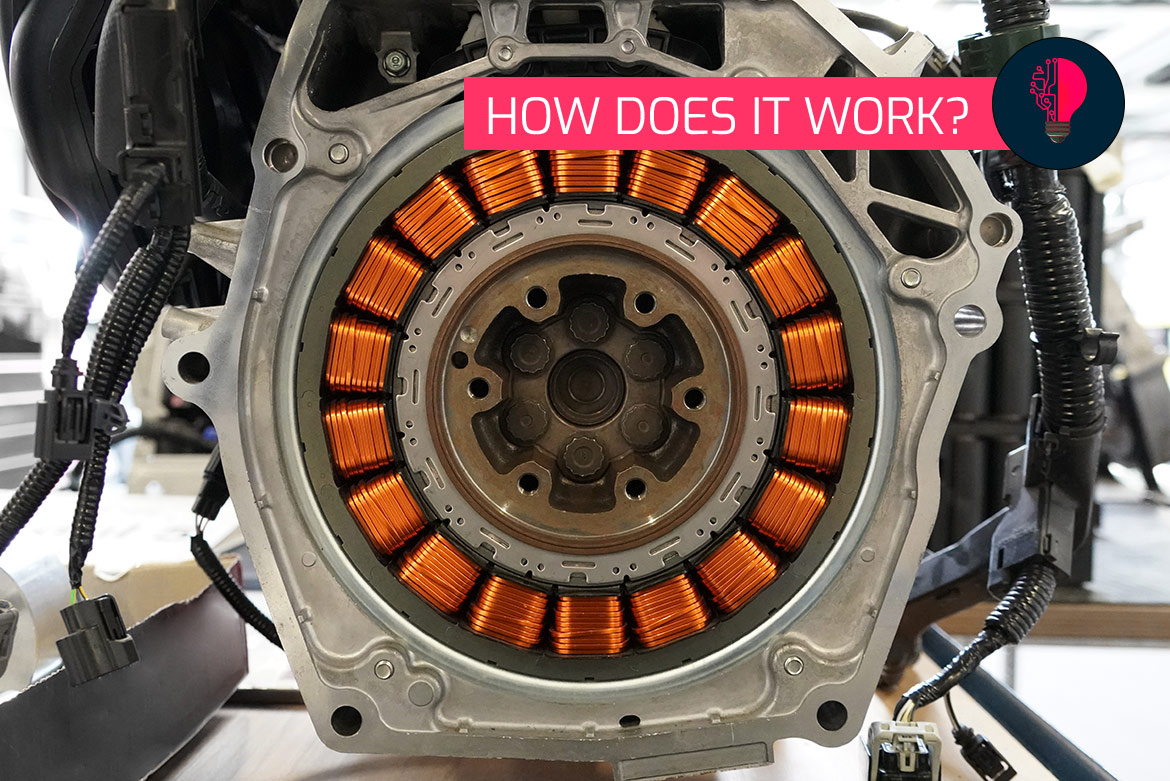

The future is “under power”: electric motors will be used in many places in the future – from cars to heating systems – in order to avoid the consumption of fossil fuels. The basic principle of a conventional electric motor is always the same: magnetic fields drive a shafts. How exactly does it work?

In the heart of the Eifel region, around 50 kilometers from Koblenz, Bharat Forge Daun mechanical production works at the highest level, producing extremely precise, rotationally symmetrical series components, among other things. This means that challenges like difficult surfaces and positional arrangements are common. Several EMAG machines are currently being used in the production of a stator housing for electromobility – with a focus on process reliability. In the following interview, Christoph Steffens, Head of Mechanical Production at Bharat Forge Daun, explains the reasons for using EMAG machines and why EMAG service is so important.

In the rapidly developing world of electromobility, precision and efficiency play a decisive role in production technology. The HLC 150 H high-performance gear cutting machine from EMAG KOEPFER represents a revolutionary solution in this context. This machine, which is characterized by its universality, precision and performance, was specially designed for the demanding task of machining tooth profiles in electric car components. With the increasing demand for quiet and efficient electric vehicles, the requirements for the machining quality of the components are also increasing. The HLC 150 H meets these challenges with advanced technology and an impressive range of machining options. In this blog post, we take a look at the special features and technical innovations of this machine and shed light on how it is driving production in the e-car sector.

The integration of robot technology into manufacturing processes is playing an increasingly important role in the modern industrial landscape. Jan Gotthold, Product Manager at EMAG Maschinenfabrik, provides an exciting insight into this area. Using EMAG’s drive shaft production line as an example, he demonstrates the key benefits of this technology.