Saldatrici laser

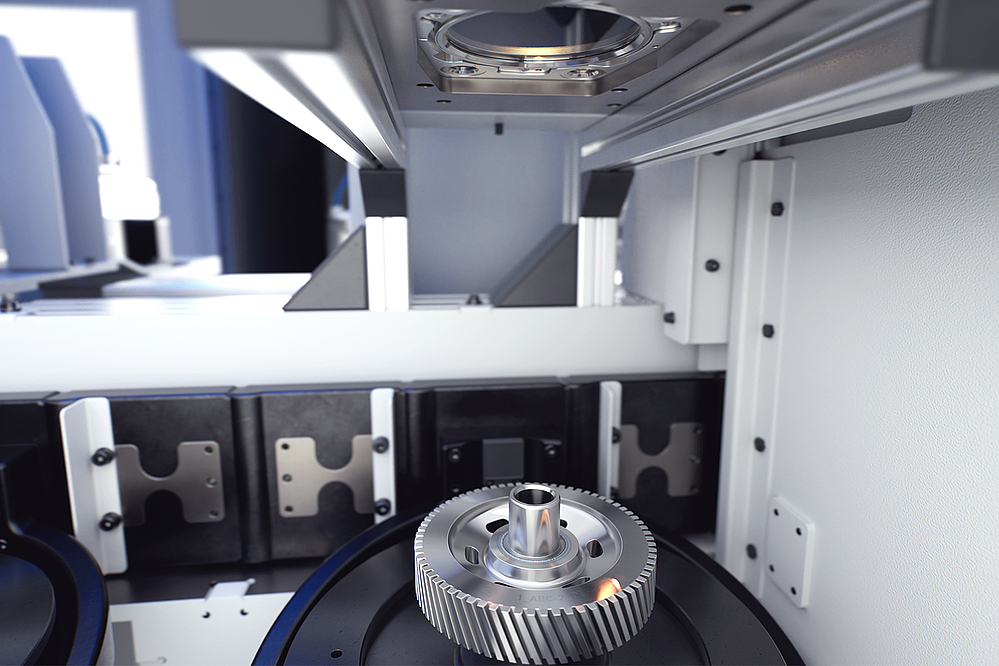

ELC 6i

- External diameter, max.: 300 mm | 12 in

- Altezza del pezzo, max.: 300 mm | 12 in

- Axial welding diameter: 75 / 200 mm | 3 / 8 in

ELC 6i - Compact standard solution for industrial laser welding

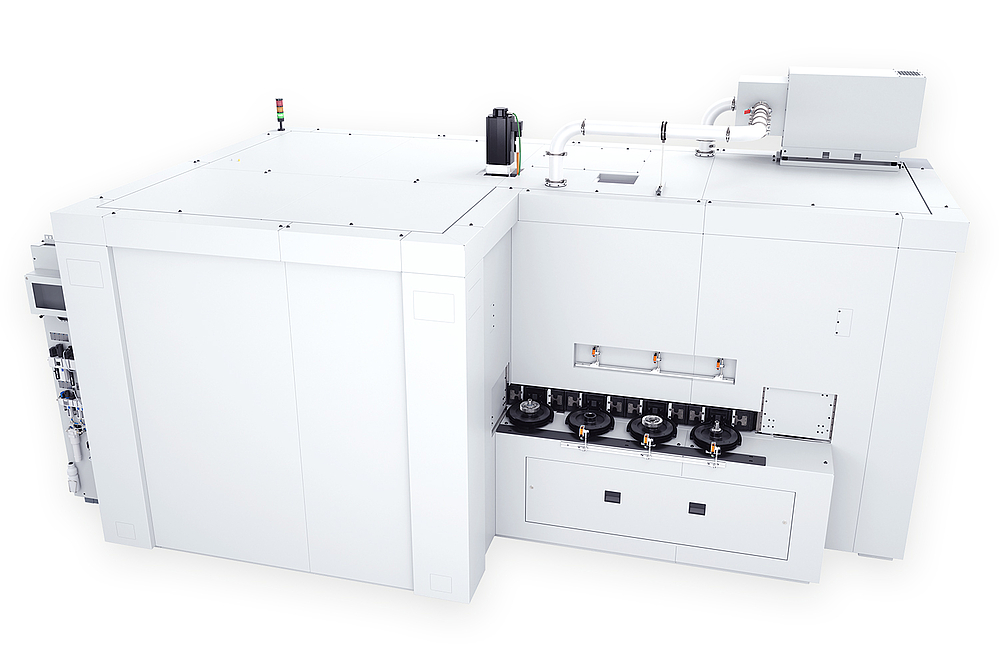

The EMAG ELC 6i is a fully automated laser welding system that integrates up to six process steps in a single machine. Its standardized concept minimizes engineering effort, reduces investment costs and shortens delivery times – all without compromising on precision and process quality.

Key features at a glance:

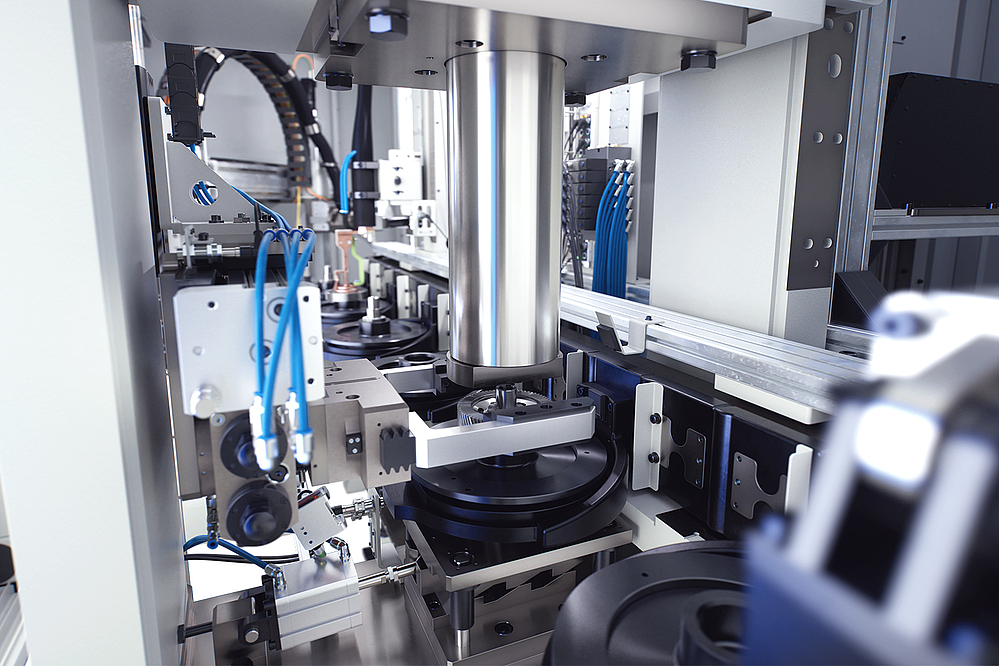

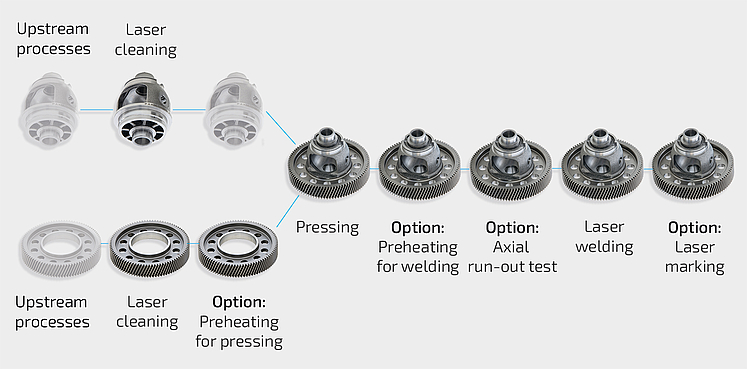

- Process integration: laser cleaning, preheating 1 (option), joining, preheating 2 (option), laser welding, marking (option)

- Compact design: only approx. 21.5 m² footprint, up to 36% less space required than conventional lines

- High productivity: cycle times under 20 seconds with a fixed transfer system and up to 18 workpiece carriers

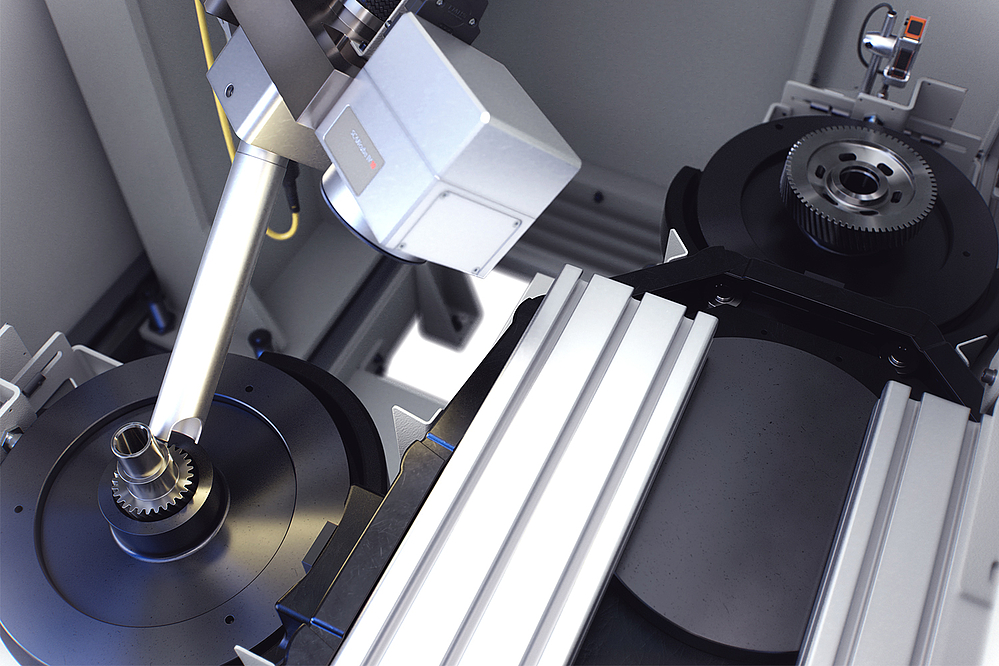

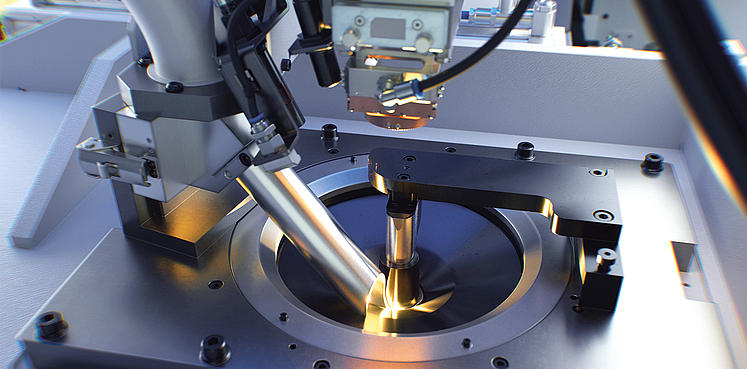

- Process reliability: proven multi-axis kinematics for high-precision welding processes

- Cost-efficiency: up to 15% lower investment costs and up to 10% shorter delivery times.

Integrated process sequence - laser welding in a continuous line

The ELC 6i delivers a fully integrated process chain, with each step automated and seamlessly connected within the system:

- Loading and unloading - two stations for raw-part placement and two stations for removing the finished assemblies.

- Laser cleaning - precise removal of impurities and coatings on the joining surfaces.

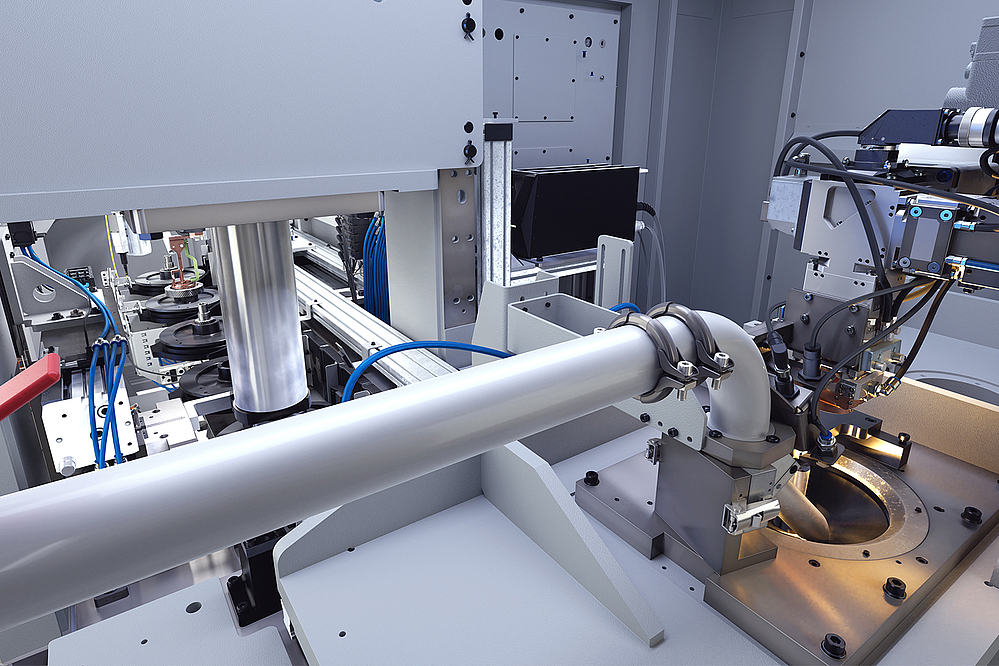

- Inductive preheating 1 (optional) - reduces pressing forces and improves weld seam quality.

- Joining (pressing) - force-displacement-monitored pressing process using a servomechanical unit.

- Inductive preheating 2 (optional) - improves weld seam quality with challenging materials and / or component geometries

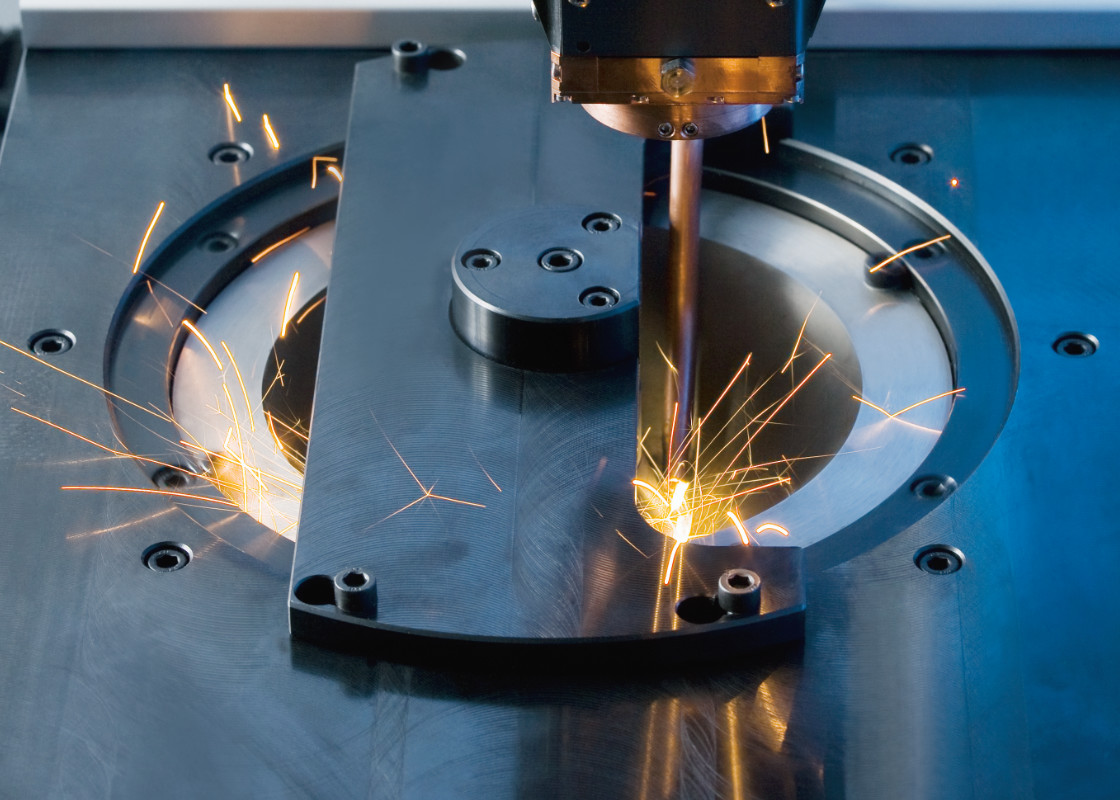

- Laser welding - high-precision circumferential welding with optional wire feed and seam position control.

- Marking (optional) - component marking by laser or needle marking for traceability

Application areas of the ELC 6i

The standardized design of the ELC 6i delivers measurable economic benefits for users.

Ideal applications include:

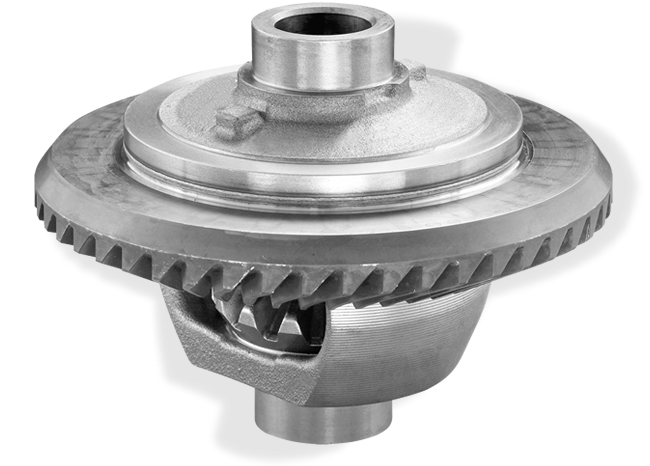

- Differentials and transmission components

- Rotor and intermediate shafts

- Components with circumferential weld seams

The system is especially well-suited for high-volume, price-sensitive production projects.

Vantaggi ELC 6i

- Reduced footprint: up to 36% smaller than comparable systems.

- Faster delivery: up to 10 % shorter lead times with predefined modules.

- Lower investment costs: up to 15 % cost savings through standardized assemblies.

- High availability: simplified spare parts management and service-friendly design

- Short changeover times of less than 20 minutes for component-specific adaptations.

Pezzi

The Right Manufacturing Solution for Every Workpiece

Tecnologie

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Laser welding is a precondition for compact, weight-optimised components and thus for energy- efficient vehicles. Adjustable doses of concentrated…