Machines de grattage

RASO 200

- Module range: mm 0.5 - 5.0

- Ø max. de la pièce: 200 mm | 8 in

- Longueur maxi. de la pièce: 100 mm | 4 in

Shaving Machine RASO 200

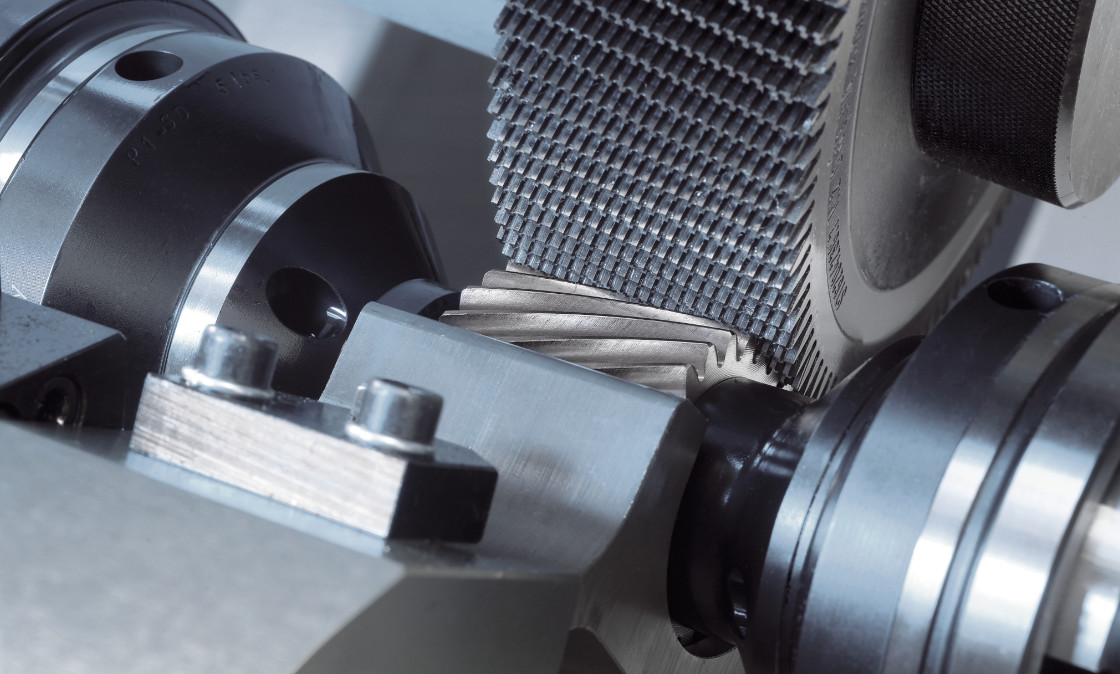

The RASO 200 shaving machine is the ideal match for automatic transmission gears, motorcycle gears, pump gears.

RASO 200 Shaving Machine for Automatic Transmission Gears, Motorcycle Gears & Pump Gears

Thanks to its “lathe-like” structure and its compact design, RASO 200 shaving machine has the same stiffness of larger machines.

Cycle speed and flexibility are at the top. The RASO 200 shaving machine is the ideal match for automatic transmission gears, motorcycle gears, pump gears. It is available in 3, 5 and 7 controlled axes configuration (modular concept).

RASO 200 is able to perform five different cycles:

- Plunge

- Parallel

- Underpass

- Diagonal

- Mixed Cycles

Avantages RASO 200

- All shaving processes are possible depending on the axes configuration

- Very fast internal automation with a rotation drum

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Gear shaving takes place before the hardening process and is a cost-effective process. It results in low-noise gear surfaces - a major benefit that…

Informations techniques

Module range

0.5 - 5.0 mm

Ø max. de la pièce

200 mm

8 in

Longueur maxi. de la pièce

100 mm

4 in

| Module range | mm | 0.5 - 5.0 |

| Ø max. de la pièce |

mm

in |

200

8 |

| Longueur maxi. de la pièce |

mm

in |

100

4 |

| Outside diameter, max. |

mm

in |

200

8 |

| Max. face width (Plonge) | mm | 100 (42) |