Ready-to-Ship EMAG Stock Machines

Get immediate access to high-performance vertical turning, hobbing and grinding systems – fully capable, field-ready and optimized for U.S. production.

Ready-to-Ship EMAG Stock Machines – Ready to Deliver. Ready to Perform.

When production deadlines can’t wait and capacity must scale yesterday, EMAG’s Stock Machines are your strategic advantage. We’ve stocked select, high-demand machines – already configured, inspected and ready for immediate U.S. deployment. No extended lead times. No guesswork. Just performance you can rely on from day one.

Why “In Stock” Matters

- Instant availability. With machines already in inventory, you avoid long wait cycles and start machining faster.

- Predictable delivery. Reduce downtime, shorten ramp-up and keep you supply-chain on track.

- High-performance equipment. These are the same high-precision platforms that power automotive, aerospace, defense and medical manufacturing.

- Configured for automation. Every model can be paired with EMAG automation systems: gantry loaders, basket stacking, TrackMotion cells – enabling labor reduction, improved consistency and scalable output.

- Purchased EMAG equipment may qualify for accelerated depreciation under section 179 (consult your accountant for details)

U.S. Stock Machine Line-Up

Here are the machines we currently have in stock and ready for U.S. deployment:

WPG 7 – Compact OD Cylindrical Grinder

In Stock in Four Configurations:

0° and 30° wheelhead versions | With or without automation

The WPG 7 combines precision, flexibility and a compact footprint – making it the ideal solution for smaller components up to 250 mm in grinding length. Built for manufacturers who demand consistent performance with minimal setup and floor space, the WPG 7 includes features that competitors list as options – all standard.

- Compact footprint: 1.8 x 2.4 m

- FANUC Oi-D control system

- Max part length between centers: 380 mm / 15 in.

- Grinding wheel Ø500 × 80 mm (CBN or aluminum oxide)

- Optional integrated gantry automation for unattended production

- Standard in-process gauging, crash detection, mist extraction, filtration

Flexible Configuration:

The WPG 7 is available in 0° (straight) and 30° (angular) grinding versions, giving you the flexibility to match your process requirements and floor space – whether manual loading or full gantry automation.

G 375 H – High-Performance Gear Profile Grinder

The G 375 H delivers maximum gear-grinding precision for automotive, aerospace and defense applications. This machine ensures short setup times and high repeatability for medium-to-large batch production.

- Grinding range up to Ø375 mm

- CNC dressing and profiling of grinding worms

- Ideal for cylindrical and bevel gears, shafts and e-drive components

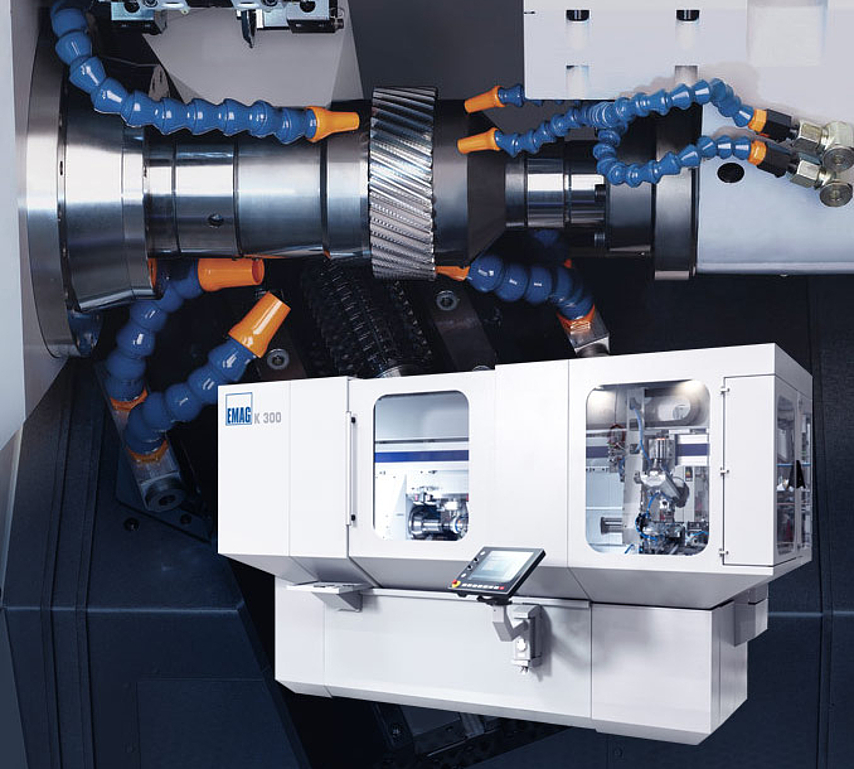

- Perfect complement to the K 300 hobbing machine for a complete gear-manufacturing cell

K 300 – Gear Hobbing Machine

A compact powerhouse for fast, precise gear production. Designed for productivity, accuracy and reliability in gear machining.

- Workpiece Ø up to 200 mm / 8 in.

- Hob spindle max speed 4,000 rpm

- Designed for high-speed dry or wet hobbing

- Suitable for powertrain and EV gear manufacturing

VL 1 Twin – Twin-Spindle Vertical Turning

Twin-spindle vertical turning with integrated part handling. Two spindles mean twice the productivity for small-to-medium part machining.

Ideal for: High-volume production in automotive and industrial applications.

VT 2 – Vertical Turning Center for Shaft Components

Purpose-built for shaft machining, the VT 2 delivers high precision and repeatability for medium-batch production with quick setup.

Max Workpiece Ø: 100 mm x 400mm length |

Spindle Speed: 5,000 rpm

VL 6 – Large-Capacity Vertical Turning

Handles larger components up to 300 mm Ø with power and precision. Built for versatility and reliability in demanding production environments.

Spindle Power: 39kW / 52hp

Automation Options

Reduce labor | Improve Consistency | Scale Output

Every stock machine can be paired with EMAG’s smart automation systems:

- TrackMotion – Linear automation for part transfer and cell linking

- Basket Stacking Systems – Compact, efficient loading for small parts

- Gantry Automation – Ideal for grinders and turning centers

- Robot Interface – Seamless integration for flexible automation cells

Industries Served

Automotive | Aerospace | Defense & Munitions | Medical | Agriculture | Energy

Start producing sooner.

Your next machine is already here – inspected, tested and ready to ship.