How can particularly large and heavy components be produced using lean production solutions? This question is becoming increasingly important, especially in the commercial vehicle sector, because price pressure in the market demands the lowest possible unit production costs. In this context, the VSC 500 and VSC 500 DUO machines from EMAG are real “game changers” for manufacturers. They load themselves and then ensure fast and precision complete-machining in a single setup or two. A conversation with Peter Gröner from the Turning Business Unit at EMAG about the enormous possibilities of this technology.

Technologies

High precision, fast processes, small footprint – the VSC 500 and VSC 500 DUO vertical pick-up machines ensure efficiency in the machining of large components, such as those required in the commercial vehicle sector. They load themselves and then start complete-machining in a single setup or two setups (DUO).

In the world of machine tools, the optimal design of processes is crucial to achieving the highest precision and efficiency. In today’s blog article, we spoke to Jörg Lohmann, Head of Technology and Product Management and Member of the Management Board at EMAG KOEPFER, to find out more about how hobbing processes are designed, using planetary gears as an example. Jörg Lohmann brings almost 20 years of experience in the design and application of gear hobbing machines and gear cutting processes and gives us a deeper insight into the decision-making behind these processes.

Sabatti Spa is a renowned family business whose origins go back 350 years with the gunsmith Ludovico Sabatti, is deeply rooted in the tradition of gunmaking. The actual company was founded in the post-war period by Antonio Sabatti and has since built a reputation for precision and craftsmanship. Under the direction of Emanuele Sabatti, the grandson of the company founder, Sabatti Spa has expanded its product range from simple gun parts to high-quality over-and-under shotguns, double-barrel shotguns and carbines. Manuel Steinhauer had the opportunity to interview Emanuele Sabatti, a visionary and technology enthusiast, who has led the company into the modern world of firearms technology without losing sight of its rich tradition and centuries-old heritage. Today, Sabatti Spa is at the forefront of innovation in firearms manufacturing, balancing time-honored craftsmanship with modern technology, making the company one of the leading names in the industry.

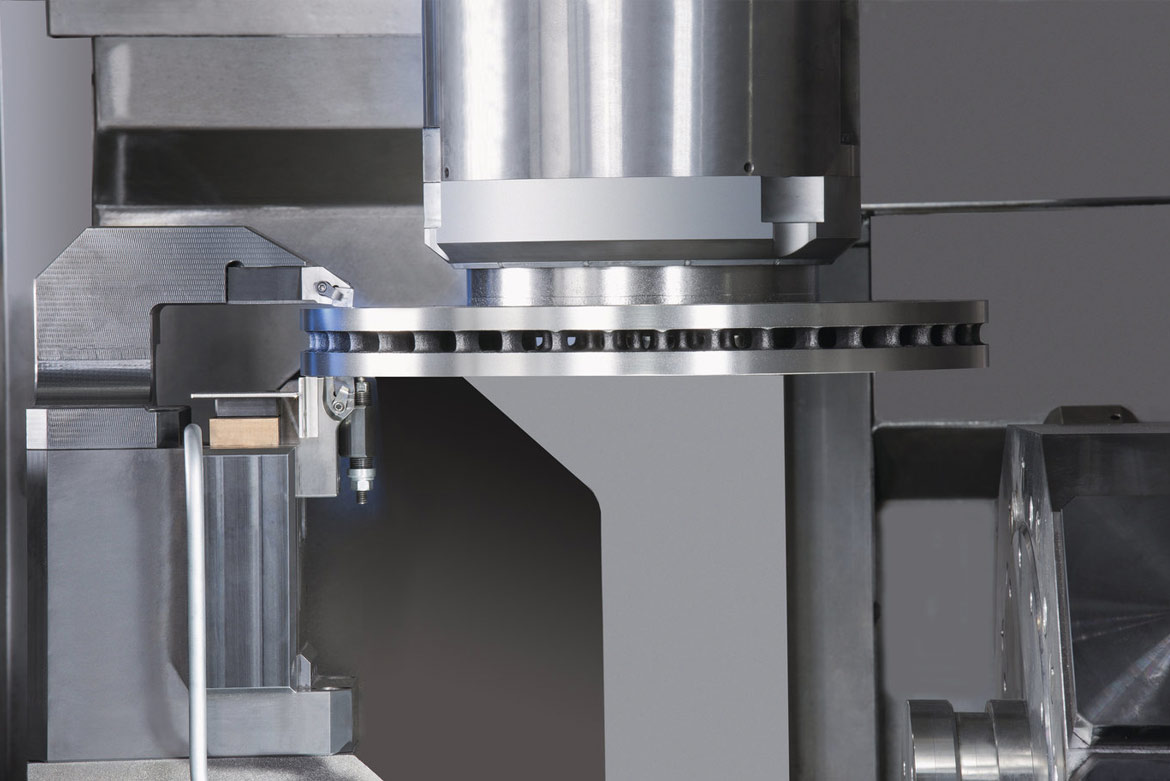

The brake disc is one of the most important safety-relevant components in passenger and commercial vehicles. The production of brake discs is, therefore, a demanding field of application that requires the highest precision. At the same time, cost pressures are very high and changing production batches must pass through the production lines with high productivity and short set-up times. As a specialist in the machining of brake discs, EMAG has already implemented numerous customized turnkey solutions in close cooperation with customers operating worldwide. In the following interview with Dominic Grimminger, expert for brake disc production systems at EMAG, we learn more about the challenges and solutions in this field of application.

The integration of robot technology into manufacturing processes is playing an increasingly important role in the modern industrial landscape. Jan Gotthold, Product Manager at EMAG Maschinenfabrik, provides an exciting insight into this area. Using EMAG’s drive shaft production line as an example, he demonstrates the key benefits of this technology.

There is no “one” big lever that can be used to improve the energy efficiency of machine tools. Instead, it is important to take a holistic view of all energy flows and that is EMAG’s approach, which the specialists apply to every new development as well as to the retrofitting of older machines. In conversation with Konrad Heimbach, Lead Engineer Energy Efficiency, it becomes clear that even relatively simple measures can massively reduce energy consumption.

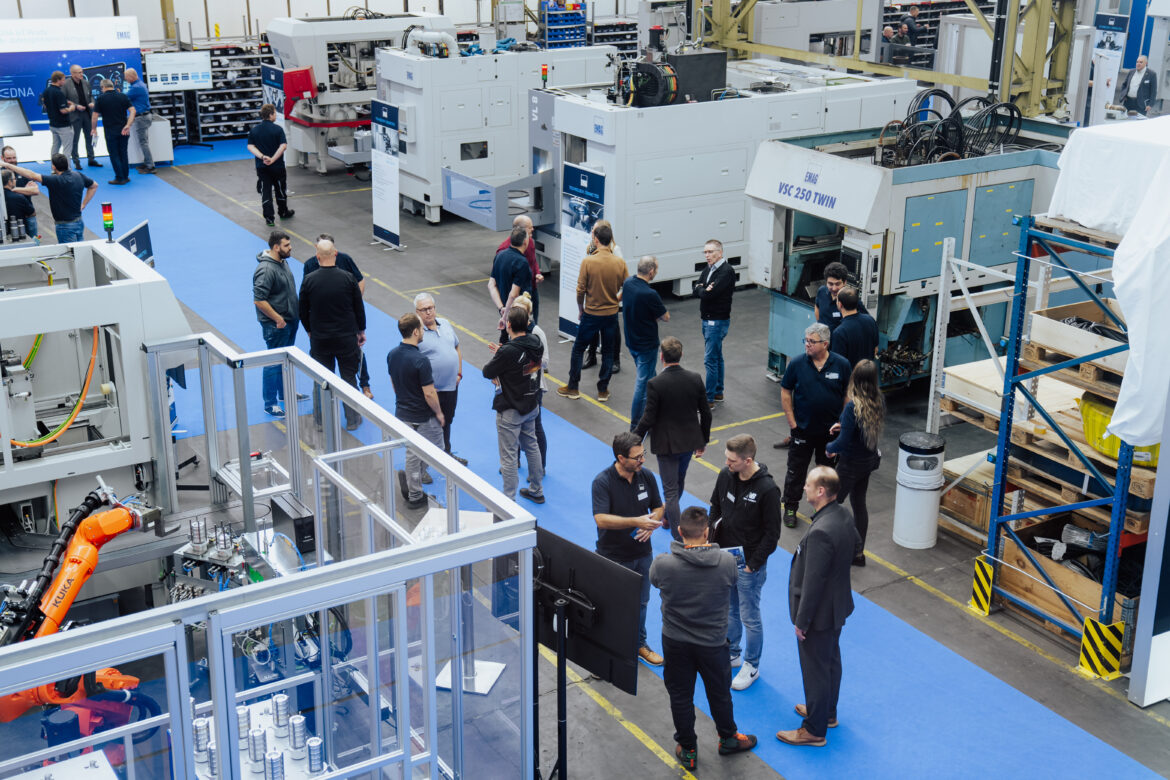

During the Open House Retrofit at the Eislingen plant, EMAG presented the future of industrial machine modernization. Visitors had the opportunity to experience the latest technologies and retrofit solutions at first hand.

With the Health Check, EMAG offers its customers an IoT tool for the health assessment of feed axes and spindles in order to better plan their maintenance periods. In addition, EMAG is constantly developing this solution further, as Patrick Kaiser, data scientist at EMAG, emphasizes in the interview: “The experience and our service flow into this in a targeted manner.”

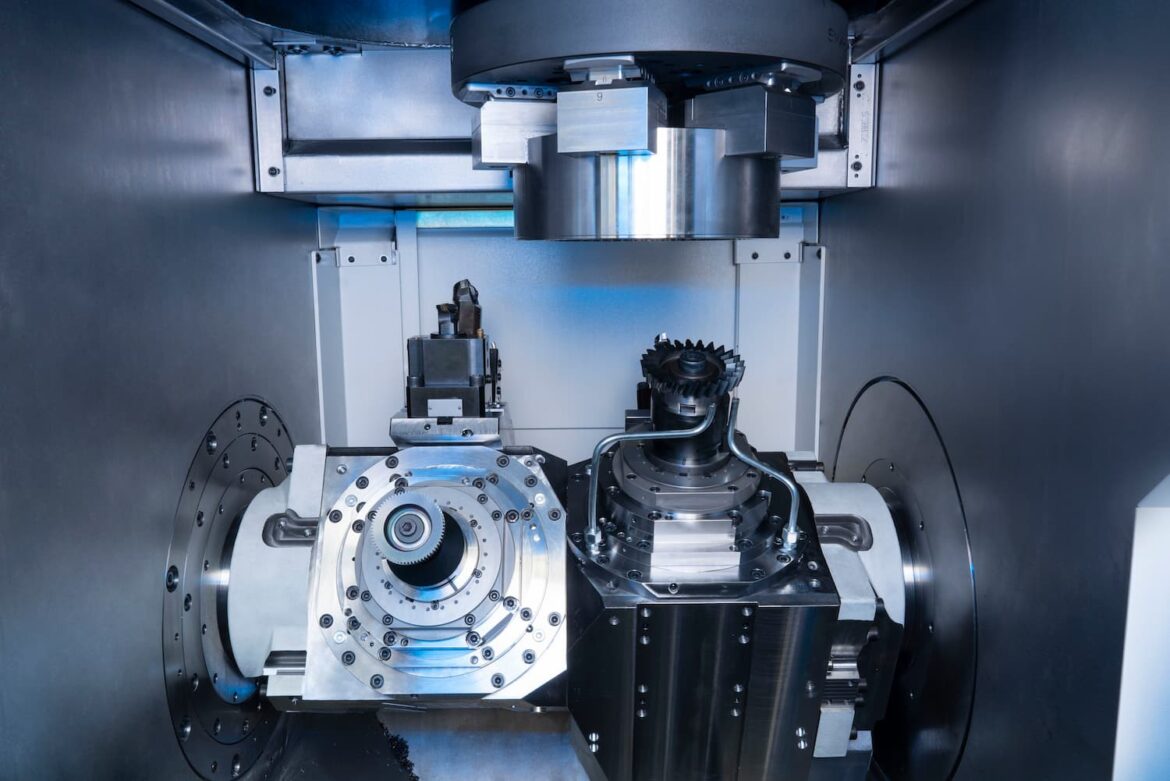

Faster than shaping, more flexible than hobbing and broaching – in this context, power skiving is a highly effective alternative for gear production. With the new VSC 400 PS machine, EMAG puts the crown on this approach by providing up to four power skiving tools and six turning tools, ensuring highly effective combination machining. And, its operation is simple. A conversation with Daniel Nille, Head of Technology Development at EMAG Maschinenfabrik, discusses the possibilities of this approach and the potential returns of investment.