Bin Picking Automation

Bin Picking Automation: The Reach Into The Box

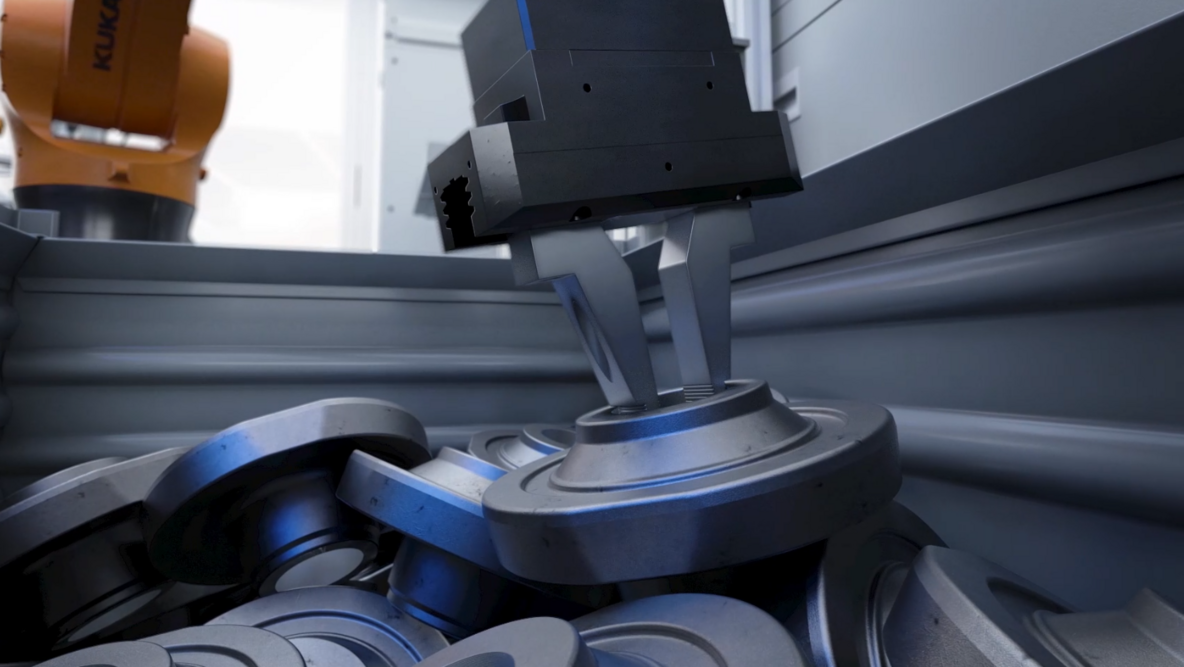

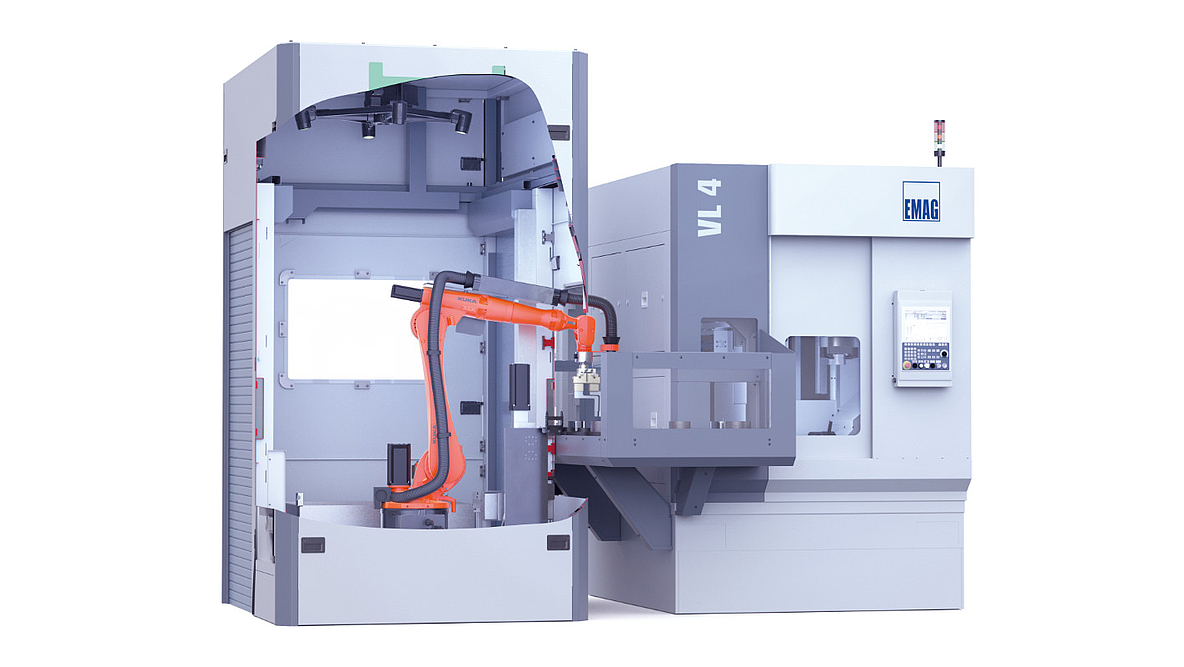

Bin picking, or "reaching into the box,” is a technology in which a robotic arm uses a 3D sensor system (3D camera, scanner, ...) to remove workpieces in a chaotic position from a mesh box or similar. The automation then correctly aligns the parts and feeds them to the next processing step. This can be, for example, the loading of an EMAG pick-up lathe. Bin picking is ideal for automated handling of workpieces such as saw cuttings or forged parts in chaotic feed or when high flexibility is required.

Bin Picking Systems from EMAG

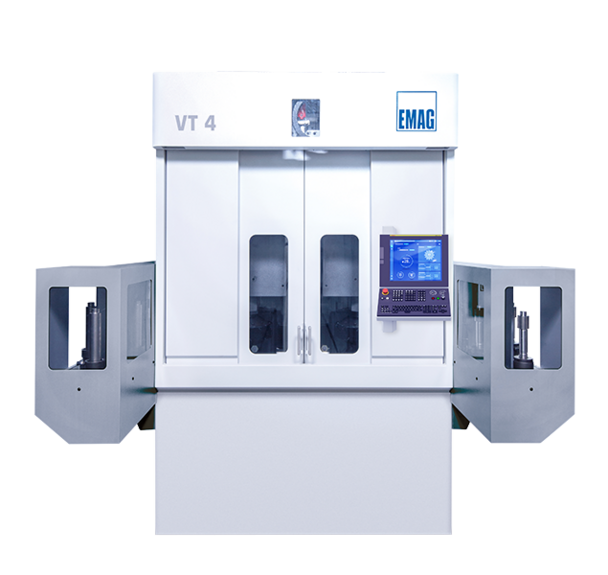

EMAG machines are already highly automated production systems in themselves. Both the machining of workpieces and the loading and unloading via pick-up spindle from the integrated workpiece conveyor are fully automated. With this pick-up interface, EMAG machines can be easily expanded into fully automated production systems.

An essential factor for the fully automated production system is the continuous feeding of the raw parts as well as the removal of the finished parts into and out of the machining process. All that is required is a constant flow of parts to the workpiece conveyor integrated in the machine.

With chaotic delivery of the unmachined parts in a bundle, continuous feeding of the workpieces was originally only possible by manual loading - until now!

The high-performance optics for 3D storage recognition enables fully automatic loading of the machines directly from the crate. The system can be used flexibly and configured for many applications. Find out more about the possible applications of the Bin Picking System from EMAG for your production projects without obligation.

Ventajas Bin Picking Automation

- Collision-free movement of robotics through real-time 3D position detection and dynamic path planning.

- High-precision part recognition (repeatability +/- 0.4 mm for a size of 1.260 x 1.260 x 1.000 of the removal area).

- Work cycle approx. 10 seconds; depending on the workpiece.

- Robotics and gripper system adaptable to a wide range of applications

- Combination with other automation solutions possible (e.g. conveyor belts)

- Application-specific camera modules for a wide range of applications

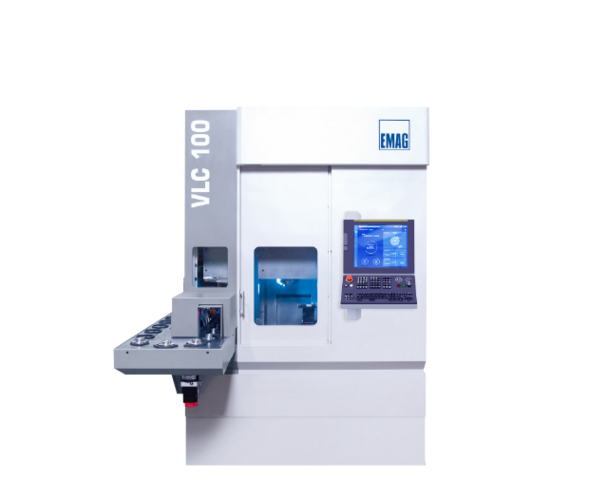

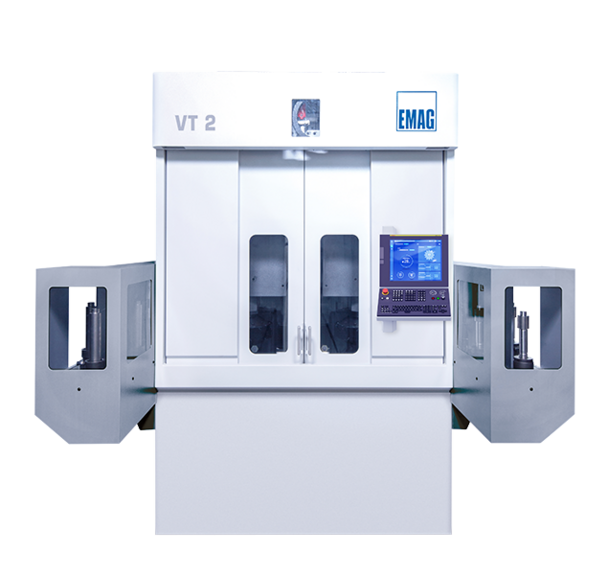

Máquinas para sus necesidades

(15) máquinas encontradas