Máquinas ECM / PECM

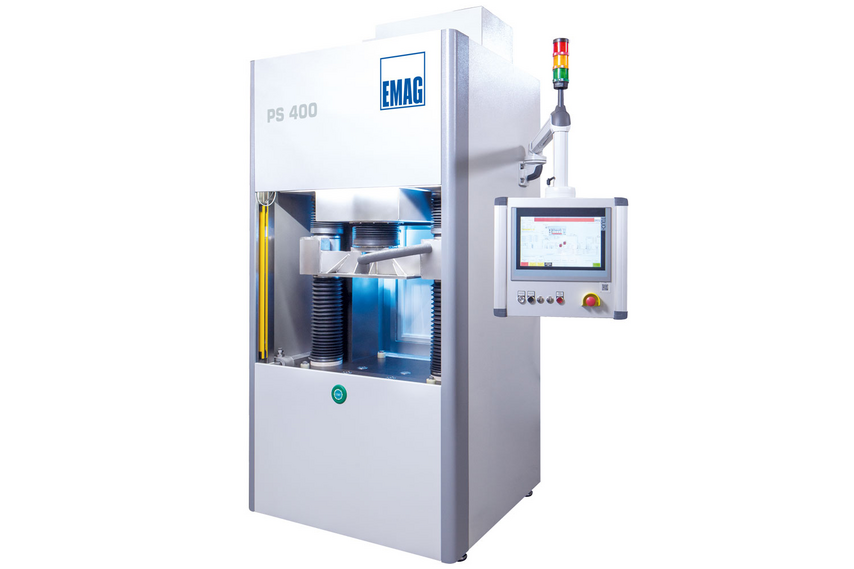

PS - Premium Standard

- Generator capacity: A (DC) 400 – 2.500

- Generator capacity: A (Pulse) 400 – 8.000

PS – PREMIUM STANDARD: Flexible Machine Platform for Electro-Chemical Machining

The PS machine with a deburring, sinking , or oscillation module is the flexible machine platform for the (P)ECM process:

- Modular machine concept

- Manual or semi-automatic starter systems

- Suitable for automation using robots or gantry loaders

- Smart software and hardware interfaces

PS - (P)ECM Precision Machining in Modular System

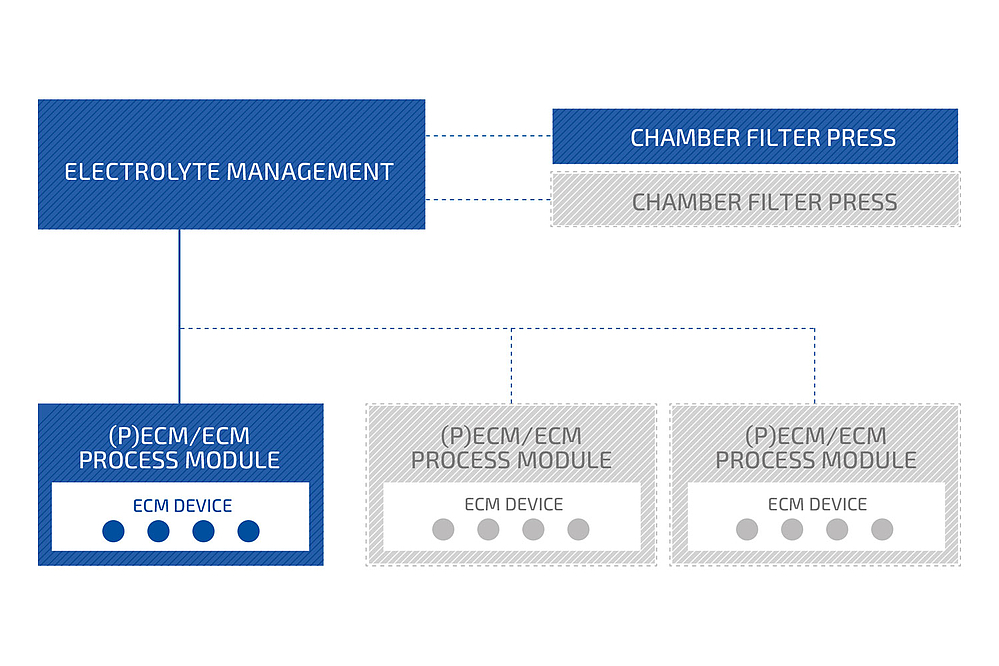

The PS single machine provides the basis for a modular system. This reduces investment costs because customers only have to invest in linking several processes (e.g., pre-washing, (P)ECM station, (P)ECM station 2, final treatment, and automation) once production increases.

The PS is ideal for ...

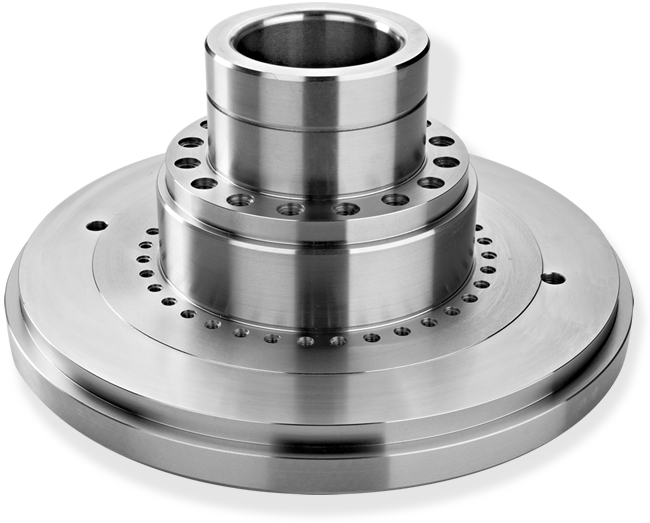

- ECM deburring

- (P)ECM internal profiling

- (P)ECM machining

- (P)ECM sinking

on a wide range of components.

The PS modules have a base made of MINERALIT®, a polymer concrete which is 8 times more resistant to vibration than gray cast iron. The machine and the tools suffer from less vibration as a result of this outstanding feature.

Highlights of the PS - Premium Standard:

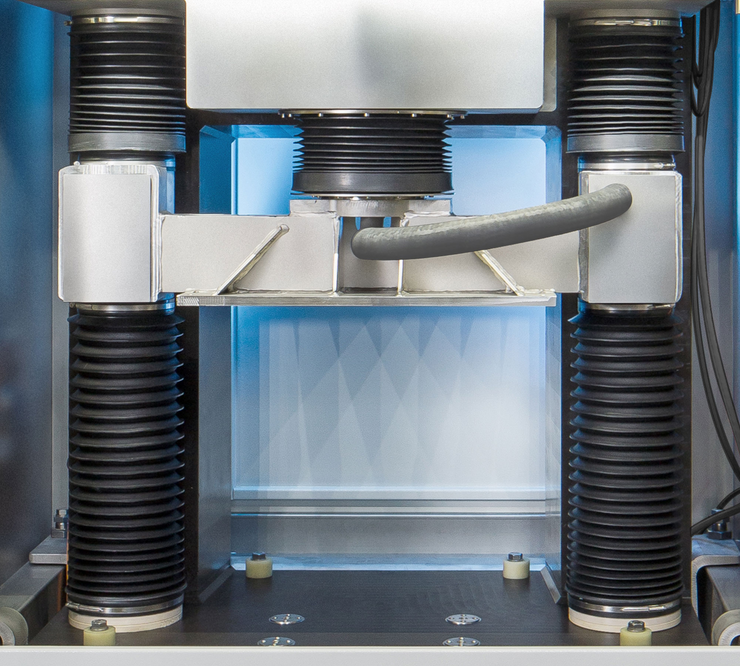

- Machining area: sinking module, oscillation module or deburring module

- Scalable generator technology up to 2,500 A

- DC, Pulse and PECM technology

- Flexibly configurable pulse technology

- Individual cathodes can be selected/deselected

- Single cathode monitoring

- Process control using time, distance, and ldt

- In the form of a sinking module: 400 mm Z stroke

- In the form of an oscillation module: 200 mm Z stroke

- Touch panel and S7-1500 controller from Siemens

- Conductivity monitoring

- Temperature control

- pH value control with metering

Options:

- Fast short-circuit shutdown

- Automatic cathode cleaning

- Oscillation at up to 100 Hz and stroke from 0 to 0.6 mm

- C-axis for interpolated multiple sinking movement

- IoT Ready

- Automation interface

- Can be combined with all electrolyte management systems from 20 – 600 l/min

- Automatic machining area door

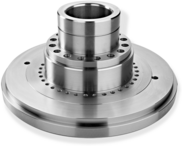

Piezas

The Right Manufacturing Solution for Every Workpiece

Tecnologías

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Electro-Chemical Machining (ECM) is the generic term for a variety of electro-chemical processes. ECM is used to machine workpieces through the anodic…

Chip-producing drilling is a fast and effective process for many applications.

However, what to do when the pressure on the tool that is supposed to…

Many components do not only have to be highly precise on the outside, but the primary focus is on generating optimal surfaces on the internal…

Datos técnicos

Generator capacity

400 – 2.500 A (DC)

Generator capacity

400 – 8.000 A (Pulse)

| Generator capacity | A (DC) | 400 – 2.500 |