Energy-efficient machine concepts

Today more than ever, the use of energy-efficient machine concepts is a decisive factor in the manufacturing industry. With increasing awareness of the impact of energy consumption on our planet and the need for cost-efficient production, it is important to choose machines and processes that get the most out of every watt. Energy-efficient machine designs involve the strategic selection and design of machines to minimize energy consumption while maximizing productivity. This includes the use of automation, reduction of non-productive time, and the use of specialized machinery such as duo- and multi-technology machines. With the right machine design, manufacturers can significantly reduce energy consumption and optimize their production processes.

Optimization of energy efficiency in production through suitable machine concepts

In industrial manufacturing, energy efficiency is an important aspect that is increasingly coming into focus. A good way to improve energy efficiency is to find the right machine concept for the manufacturing process, which at the same time can be automated to the maximum with simple means.

Automation for energy efficiency

Automation capability plays an important role in optimizing energy efficiency. A high number of workpiece transports between machines requires additional energy. Machines that are suitable for series production without requiring a high degree of automation contribute to efficiency. This can be achieved by integrated workpiece storage or simple loading and unloading options on the machines. Automation is an integral part of the majority of EMAG machines.

Reduction of non-productive times

Another strategy for energy efficiency is the reduction of non-productive times (unproductive times of the machine) This can be achieved by loading and unloading the machine in parallel with machining; this concept is called shuttle machining. Thus, by increasing productivity and reducing non-productive times, the energy required for production per workpiece can be reduced.

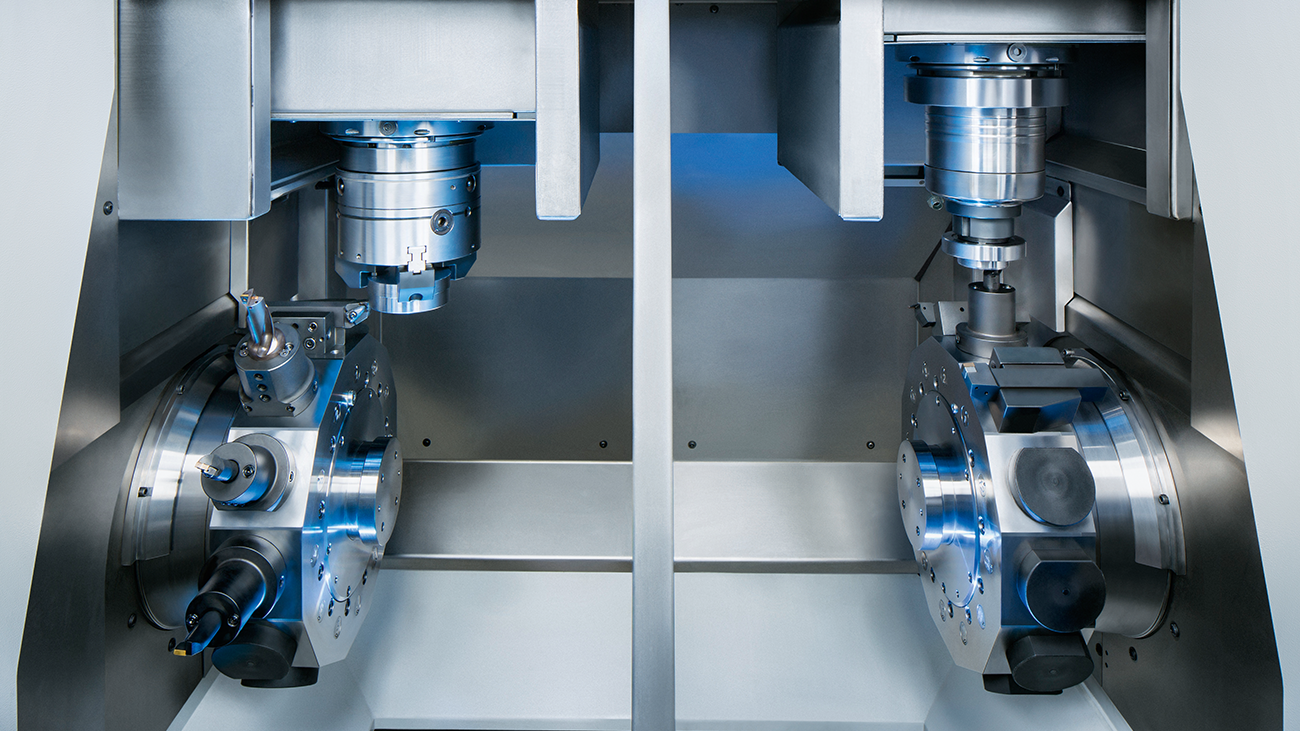

Duo machines and multi-technology machines

In duo machines, two machines share a number of peripherals such as cooling, hydraulics and control. If this concept is suitable for the process, a Duo machine can consume less energy than two individual machines.

Multi-technology machines

Further opportunities for improving energy efficiency are offered by the concept of multi-technology machines. Here, several manufacturing processes are combined on one machine. This also has the advantage that very high quality can be achieved through machining in one setup without downstream finishing processes, and at the same time significantly less workpiece handling is required than with two individual machines. In addition, the same advantages exist as with the Duo machine with common auxiliary units.

Summary

The key to improving energy efficiency in the manufacturing industry lies in choosing the right machine concept that reduces the workpiece handling effort. Specialized machines often have advantages over universal solutions because they contribute to the energy efficiency of the process. By implementing strategies such as automation, reducing non-productive time and using multi-technology or duo machines, energy efficiency in manufacturing can be significantly increased.