On the way to green manufacturing

EMAG is continuously working on improving energy efficiency in production. The strategy covers several key areas such as efficient manufacturing processes, machine design, component selection, transparent energy management and the use of modern technologies such as artificial intelligence. With a clear focus on sustainability, EMAG optimizes processes to minimize energy consumption and maximize quality and productivity.

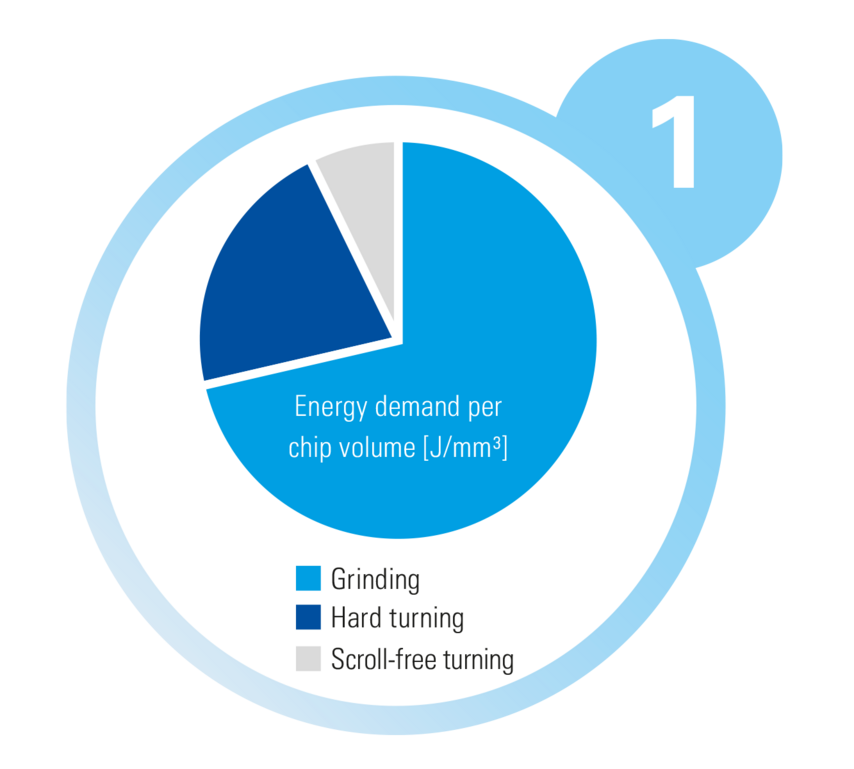

Efficient manufacturing processes

Manufacturing processes have a significant impact on energy efficiency, which is why we are constantly working to improve and optimize these processes. In doing so, we focus on the use of optimal technologies to minimize energy consumption while ensuring high quality and productivity.

More informationsEfficient manufacturing processes at EMAG

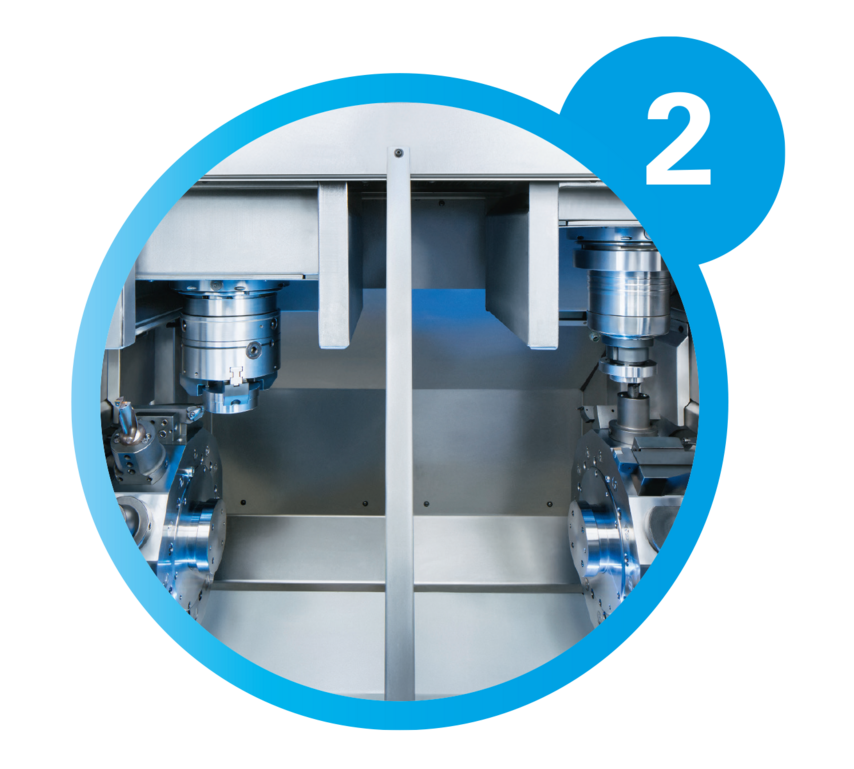

EMAG's machine concepts are designed for energy efficiency and sustainability. By developing machines that consume less energy while delivering high performance, EMAG helps reduce the environmental impact of the manufacturing industry.

More informationsEfficient components for energy-optimized manufacturing

We develop and implement components designed to minimize energy consumption and maximize performance. This includes all areas of the machine tool - from mechanics, electrics, pneumatics to hydraulics.

More informationsProactive energy management at EMAG

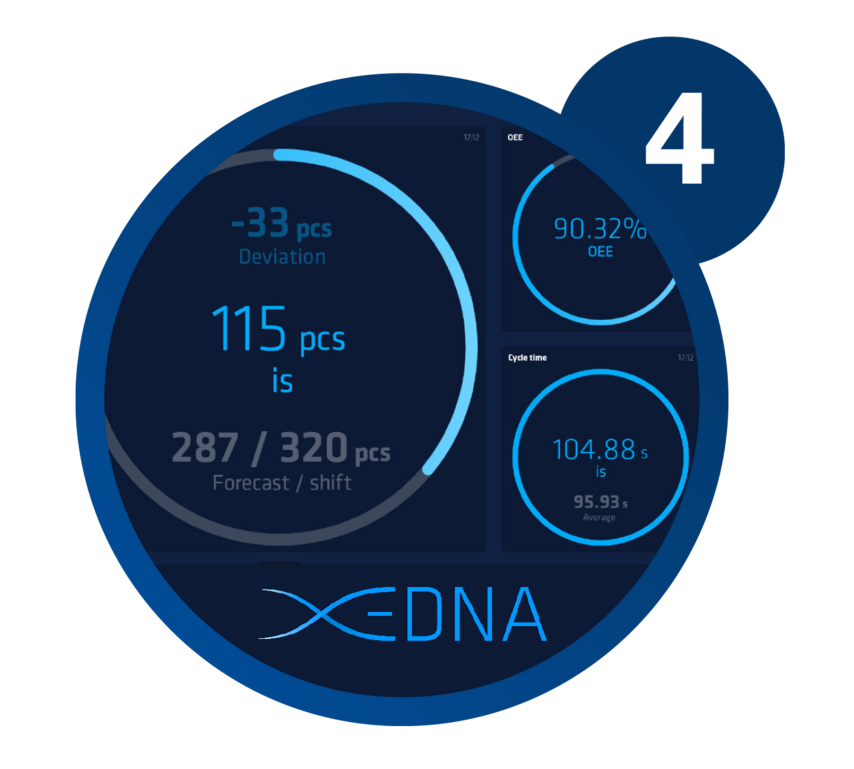

By continuously monitoring and controlling energy consumption, we can effectively identify patterns of, for example, leakage and inefficiencies in processes and identify measures to reduce energy consumption.

More informationsAI-controlled production optimization at EMAG

EMAG EDNA AI systems make it possible to identify complex patterns and relationships in large amounts of data, which are used to improve energy efficiency. This allows us to make predictions and decisions in real time to increase efficiency and productivity.

More informations