The car steering of the future will be different: largely electric and autonomous – the driver will be increasingly supported by intelligent systems. But how exactly do the various steering systems work and what role does the wheel suspension, including wishbones, play? We explain.

1. How do car steering systems work?

Modern car steering systems are a small marvel of technology that is currently undergoing major changes. Only the basic function (still) remains unchanged: When the steering wheel is turned, the system ensures that the vehicle changes direction. Beyond this, however, the focus is increasingly on optimizing the steering angle set by the driver through active assistance. In addition, steering torque and speed are intelligently adapted to the driving situation, which is possible with electric steering systems, for example. In this context, it is clear that there is not just one solution for this task (more on this below). Essentially, however, the system still consists of a steering column that connects the steering wheel to the steering gear or power steering. The gearbox in turn translates the rotary movement of the steering wheel into lateral movements, which are guided to the wheels via the so-called tie rods.

Advertisement for a so-called spindle steering system from the 1950s. The technology is no longer used today.

Source: Internet Archive Book Images, No restrictions, via Wikimedia Commons, https://commons.wikimedia.org/wiki/File:The_literary_digest_(1890)_(14597343157).jpg

2. What does all this mean for the coupled wheel suspension?

Here we come to a “neuralgic point”, because the wheel suspension not only transfers the movements of the steering gear to the wheels but also compensates for unevenness and vibrations during this process. So-called control arms or axle control arms, which connect the wheel to the vehicle body, play a decisive role. Depending on the orientation of the component, these are called transverse control arms, trailing arms or semi-trailing arms, whereby all variants have joints to absorb the vibrations of the wheels. Triangular control arms, for example, have three ball joints and trapezoidal control arms even have four ball joints.

View of the wheel suspension including wishbones (at the bottom of the picture).

3. What are the advantages of modern steering systems?

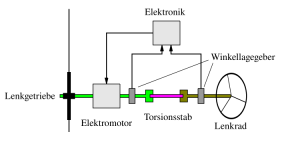

Conventional hydraulic power steering systems are increasingly replaced by electrohydraulic or electric systems. Experts also refer to the latter as Electrically Powered Steering (EPS). Here, hydraulic fluid is no longer used at all. Instead, an electric motor generates the steering movement. It is located on the steering column and generates an additional steering torque. Alternatively (and even more effectively), this motor is positioned directly on the steering rack, where it generates the necessary steering force via a toothed belt drive.

In contrast, there are still electrohydraulic power steering systems. An electric hydraulic pump is at the heart of these systems. It delivers a volume flow that amplifies the steering movement via a hydraulic cylinder. This is no different with conventional hydraulic power steering systems. However, a belt-driven power steering pump is used here.

Simplified representation of a power steering system.

Source: Stündle, CC0, via Wikimedia Commons, https://commons.wikimedia.org/wiki/File:Prinzip_elektrische_Servolenkung.svg

4. How will the systems become more secure?

“So-called active steering systems are state of the art. The system “actively” intervenes in the driver’s actions or improves them. An additional steering angle is added or subtracted to increase comfort and safety. As a result for example, it is easier to park the vehicle, because a relatively small intervention on the steering wheel is sufficient. Comparably, small interventions do not lead to any reaction when driving on the highway. This is achieved with so-called superposition systems, which are located as independent components in the steering system and introduce an additional steering torque. The associated control unit is connected to the vehicle sensors, which means that the driver’s steering impulse can even be completely blocked if he makes a mistake. It is also interesting to note that various companies rely on rear-axle steering. It is used in parallel to the front axle steering and, thus, reduces the turning circle when maneuvering or improves driving stability during evasive maneuvers.

5. What does the future hold?

Everyone has been talking about “drive by wire” for a few years now. A small revolution in the history of car development: the driver’s steering commands are transmitted entirely via electronic signals to the steering system in the front axle. In other words, there is no mechanical connection to the steering wheel at all and the steering column is no longer needed. On one hand, this construction allows new design freedom in the interior design. On the other hand, it creates a new steering feel. Example “Parking”: the steering wheel is no longer turned to the maximum but only tapped minimally. That is enough. This technology has already been in use in prototypes for some time. The first series of models will appear shortly.