Rectifieuses de profil

GP 500 H

- Domaine du module: mm 0.5 – 15.0

- Diamètre min. de la pièce à usiner: 500 mm | 19.5 in

- Longueur maxi. de la pièce: 1,250 mm | 49 in

Gear Profile Grinding GP 500 H

The GP 500 H is a profile grinding machine that mounts an additional NC axis, allowing you to work with two separate spindles instead of just one.

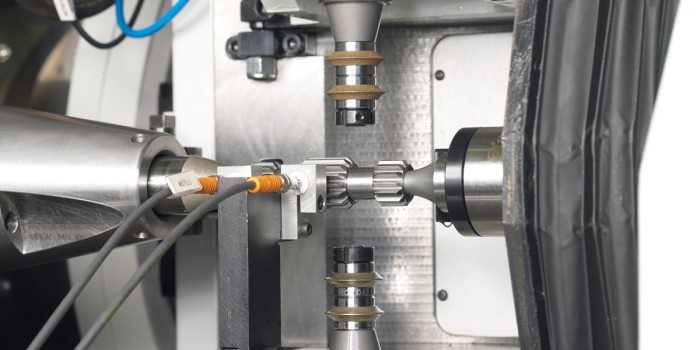

Internal Grinding through Twin Spindle Principle

The EMAG SU GP 500 H gear profile grinding machine features an array of innovations and establishes at the same time the new improved base for all machines of the horizontal profile grinding machine of the EMAG SU G series.

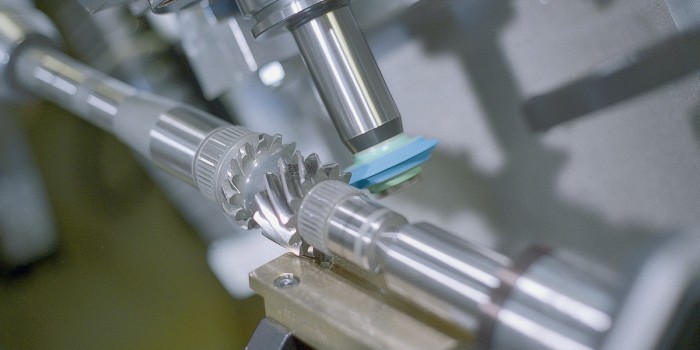

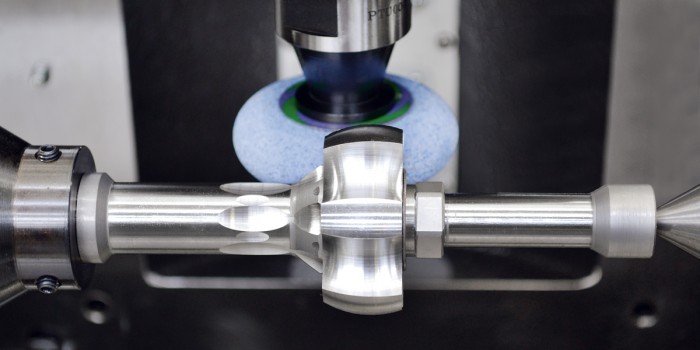

The GP 500 H is a gear profile grinding machine that mounts an additional NC axis, allowing you to work with two separate spindles instead of just one. Both spindles can accommodate one grinding wheel or even two-wheel sets. Single gearings are roughed on the first spindle and finish ground on the second, with one grinding wheel mounted on each spindle. Two gearings on one shaft can be roughed and finished with wheel sets on each spindle without the need for tool changes.

Spindle variants are available with different power outputs and speeds for different grinding wheel sizes. Even internal gear manufacturing no longer requires tool change thanks to this new twin drive principle.

Now format changes are executed considerably faster than before. This is true for changes between external and internal grinding spindles as well, since simple adapter interfaces can be connected quickly and easily by the machine operator. The GP 500 H employs electroplated CBN or dressable corundum grinding wheels depending on the workpiece requirements, delivery time and batch size to be manufactured.

Avantages GP 500 H

- Roughing and finishing in a single setup without the need for tool change

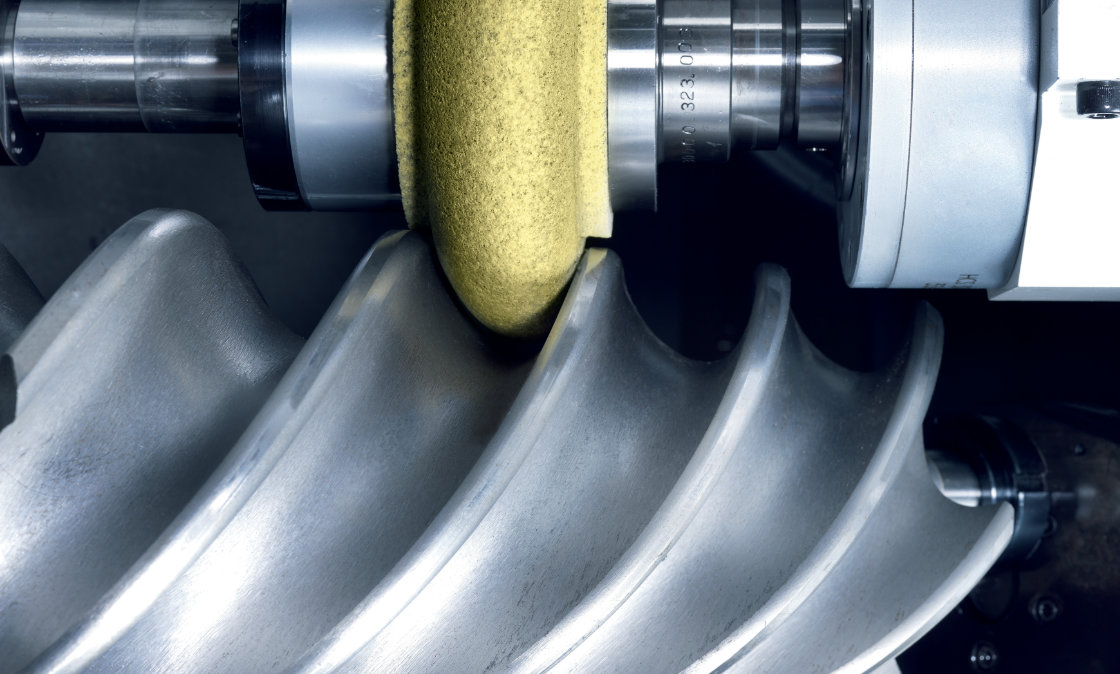

- Profile grinding of gears, shafts with separate gearings, rotors, worms and screw-type workpieces

- Internal grinding through twin spindle principle

- Fast format changes via quick-change adaptors

- Modular software

- Automation with integrated checking possible

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Profile grinding of gears and long, slim and toothed components is performed discontinuously, i.e., tooth gap by tooth gap, is completed one after the…

Informations techniques

Domaine du module

0.5 – 15.0 mm

Diamètre min. de la pièce à usiner

500 mm

19.5 in

Longueur maxi. de la pièce

1,250 mm

49 in

| Domaine du module | mm | 0.5 – 15.0 |

| Diamètre min. de la pièce à usiner |

mm

in |

500

19.5 |

| Longueur maxi. de la pièce |

mm

in |

1,250

49 |

| Profile depth, max. |

mm

in |

35

1.5 |

| Centre dist. work spindle / tool spindle |

mm

in |

15

/ 380

0.5 / 15 |