Automate maintenance with EDNA Health Inspect – Precise machine diagnostics for maximum uptime

EDNA Health Inspect is EMAG's advanced diagnostic tool specifically designed to analyze and monitor VL (Single/Duo), VSC (Single/Duo) and VT machines. It provides an automated and accurate solution for assessing machine health by detecting wear, jamming and other potential damage at an early stage, ensuring a longer service life for your machines.

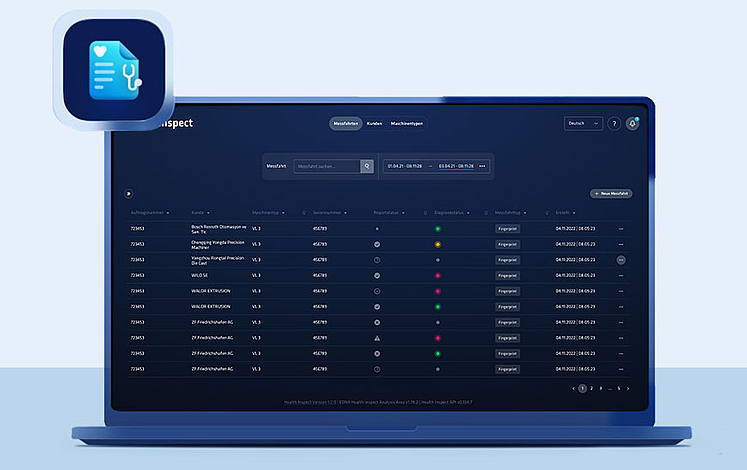

Optimize machine health: EDNA Health Inspect for accurate diagnostics and efficient maintenance

What is EDNA Health Inspect?

EDNA Health Inspect combines proven methods of machine diagnostics with high-resolution sensor technology and practical experience. This tool provides reliable analyses of machine axes and main spindles while offering detailed reports and clear recommendations for action at the touch of a button. Specially optimized for VL (single/duo), VSC (single/duo) and VT machines, EDNA Health Inspect enables efficient maintenance and minimizes unplanned downtime.

Key features of EDNA Health Inspect

- Automated analysis: Health of the machine’s main axes and main spindles is assessed automatically and precisely.

- Traffic light system: A user-friendly traffic light system shows the condition of your machines at a glance and helps to identify problems at an early stage.

- Experience-based knowledge: The expertise of our service technicians is incorporated into every analysis to ensure sound diagnoses and recommendations.

- Advanced measurement technology: New high-resolution sensors and additional control data, such as speed and current values, provide detailed insights and support more precise damage detection.

- Automated report: Detailed reports are generated, can be replicated and offer clear recommendations for action.

Health conditions that are analyzed

EDNA Health Inspect identifies and evaluates several key health conditions of your machines, including

- Stiffness: Checks the preload in the feed drive for wear and jamming

- Running surface wear: Describes the changes in surface quality of the ball screw drive’s running surfaces resulting from wear

- Geometry: Detection of geometry shifts that indicate assembly errors or damage caused by crashes

- Counterbalance: Diagnosis of problems in the counterbalance to ensure correct settings

- Spindle imbalance: Detection of possible imbalance. Quality classes are not taken into account

- Main spindle bearing: Detection of rolling bearing damage using different methods of frequency analysis

Why EDNA Health Inspect?

- Increase efficiency: By detecting and rectifying problems at an early stage, you help to maximize the uptime of your machines.

- Reduce costs: Avoid expensive repairs and downtime with preventive maintenance based on detailed diagnostics.

- Confidence in your machines: With EDNA Health Inspect, you always have an accurate overview of the condition of your machines and can make informed decisions.

Advantages

- Automated diagnostics: Increases the accuracy of machine health assessments

- Early detection of problems: Catches wear, jamming and other damage early, before they lead to major breakdowns

- Clear overview: The traffic light system provides a simple and quick overview of the machine's condition.

- Experience-based knowledge: Integration of expert knowledge for well-founded and practical recommendations

- Detailed reports: Automatically generatereports that can be replicated with clear recommendations for action

- Advanced measurement technology: Improved high-resolution sensors and integrated control data enable deeper insights and more precise analyses.

- Cost reduction: Preventive maintenance can avoid expensive repairs and unplanned downtime.

- Optimized maintenance planning: Better plan maintenance intervals with accurate diagnostic data.

- Increased machine service life: Regular and precise monitoring of machine conditions

Contact IoT

Do you have questions or need more detailed information? Please contact us!

iot@emag.com