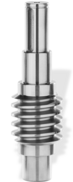

Long drive shafts for agricultural equipment, trucks and tanks

Long drive shafts are key components in the drivetrain of wheeled and tracked military vehicles. They transmit high torque over large distances, connecting transmissions, intermediate bearings and axle differentials – while also absorbing bending and torsional loads. In both combat and logistics operations, these shafts must remain dimensionally and functionally stable despitetemperature changes, vibrations and shaping.

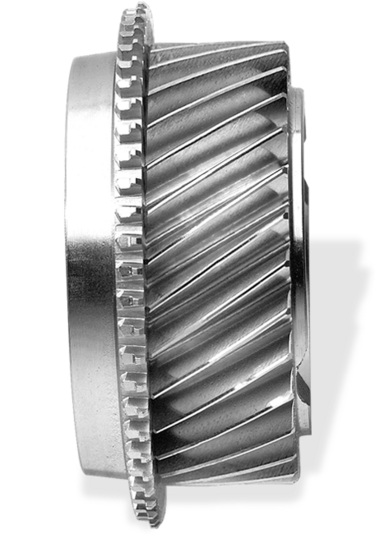

This places strict requirements on production – particularly regarding concentricity, coaxiality, tooth flank shape and phase position when tooth profiles are present at both ends. Similar long, slim shafts with gear cuts at each end are also used in agricultural machinery, such as equipment for grass processing.

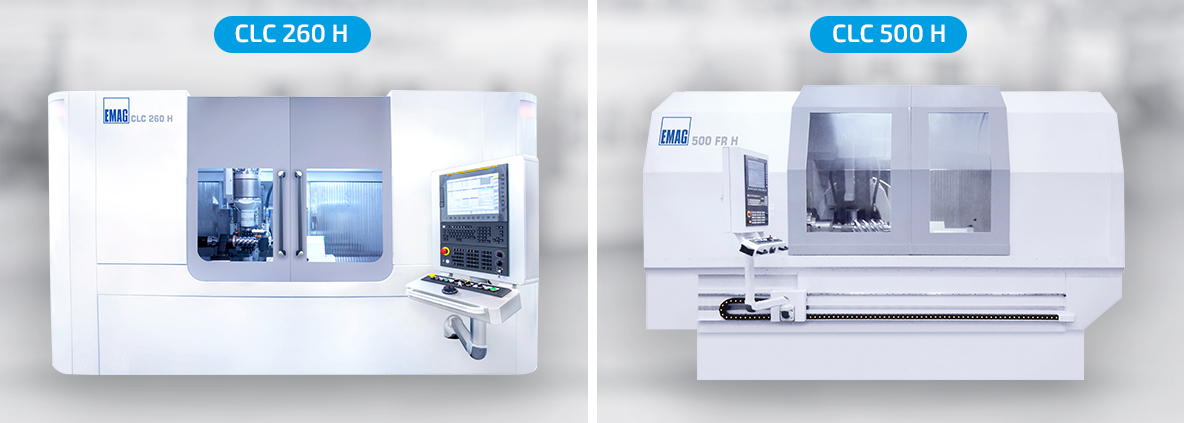

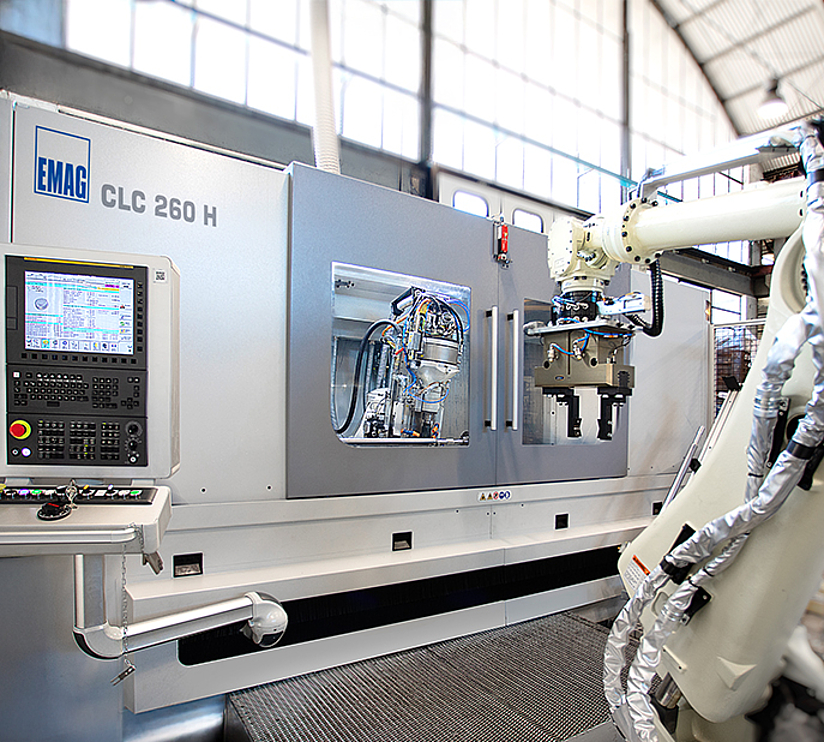

With its table through-hole design, the CLC 260 H enables the machining of shafts over 3,200 mm in length.

The CLC 260 H (FR) version can also be equipped with a special profile milling head for the production of worms, hydraulic spindle pumps and worm-shaped workpieces. A reinforced variant of the CLC 260 H – supporting modules up to 10 mm – completes the machine range.

Solutions for the machining of long drive shafts

CLC 260 H - For slim, long shafts

The CLC 260 H horizontal gear hobbing machine is designed for machining workpieces up to 260 mm in diameter and module 6. Typical applications are long truck drive shafts.

Technical highlights:

- Axial travel 1,500 mm (optionally up to 3,000 mm)

- Workpiece length up to 3,200 mm

- Direct drives on table and tool spindle

- NC-controlled steady rests for support

- Automation options with robot or gantry

CLC 500 H - For large drive shafts

The CLC 500 H extends the range of applications to large and heavy shafts. It is suitable for gear shafts, rotors and rotary pistons for air compressors and components up to module 22.

Technical highlights:

- Workpiece dia. max. 500 mm

- Axial travel 2,000 mm (optionally 3,000 mm)

- Workpiece length up to 3,200 mm (with table through-hole also longer shafts)

- Machine weight approx. 35,000 kg

- Tool sizes up to Ø 350 mm

- Designed for highly stressed components with high torque requirements

Precision through production in a single setup

A key feature is the machining of both end splines in a single setup. This avoids:

This strategy delivers maximum precision and process reliability - crucial for safety-critical drives in defense and commercial vehicle technology. |

Automation with robots for long drive shafts

Handling long drive shafts places special demands on automation systems: components must be moved gently, positioned precisely and securely clamped. Robot solutions offer clear advantages here. With specially designed grippers, even slim shafts can be safely picked and loaded into the machine without deflection. When combined with steady rest supports and NC-controlled tailstocks, the result is reproducible and damage-free clamping.

Robot automation also enables production flexibility – allowing different shaft lengths and diameters to be machined without extensive set-up times. Additional process steps such as deburring or cleaning can be integrated directly into the handling cycle. For operators, this means shorter lead times, lower personnel costs and stable batch production with consistent quality - even with varied batches.

The production of long drive shafts requires the highest precision and stable processes. With the CLC 260 H and CLC 500 H machines, EMAG offers customized solutions for the entire range - from light commercial vehicles to heavy defense platforms.

Users benefit from reduced lead times, verifiable quality and robust batch production, even with long component lengths and demanding tolerances.

Machines

(1) machines trouvées

Workpieces

Technologies

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Flexible, highly productive, highly accurate - as a continuous gear production process, hobbing is indispensable in many industries, as it allows any…