Meet with EMAG L.L.C. at our 30th Anniversary Open House!

Dates: June 19- 20, 2024

Opening Hours: 12 pm – 7 pm EST

Location: 38800 Grand River Avenue, Farmington Hills, MI, 48335, USA

register now

We’re proud to announce that we’ve been serving our North American customers from Farmington Hills, Michigan for 30 years. Please come celebrate our milestone with us.

Discover our latest innovations and technologies for automated machining and gear manufacturing. Meet our experts in person and find out how our solutions can optimize your manufacturing processes. We look forward to welcoming you.

Our Event Highlights:

VL 6 - Modular Vertical Lathe Fed by a SCS4 Stacker

Like the newest EMAG modular designs in vertical turning machines, the VL 6 vertical lathe offers the same features but is constructed for larger, heavy workpieces. Equipped with a standard workpiece conveyor and pick-up spindle, the cnc lathe loads itself with minimized chip-to-chip times. We’ve gone a step further and added a SCS4 stacking cell, which allows the VL 6 to produce autonomously for hours. The excellent damping quality of the machine‘s polymer concrete MINERALIT® base extends tool life and providers outstanding surface finishes as well.

VT 4 - Turning Center for Demanding Shaft Production

Short cycle times, high precision and integrated loading and unloading make shaft machining on the VT 4 very cost-effective. Chip-to-chip times are extremely low, massively reducing components costs since workpiece grippers transfer the raw parts into the turning center and pick them up again after machining. Depending on the workpiece, this changeover time lasts only about six seconds. Even the actual turning process is fast. The component is machined simultaneously from two sides using 4-axis machining. In addition, the free downward chip flow avoids chip build-up in the machine compartment, and ensures long-lasting process reliability and less tool breakage and wear.

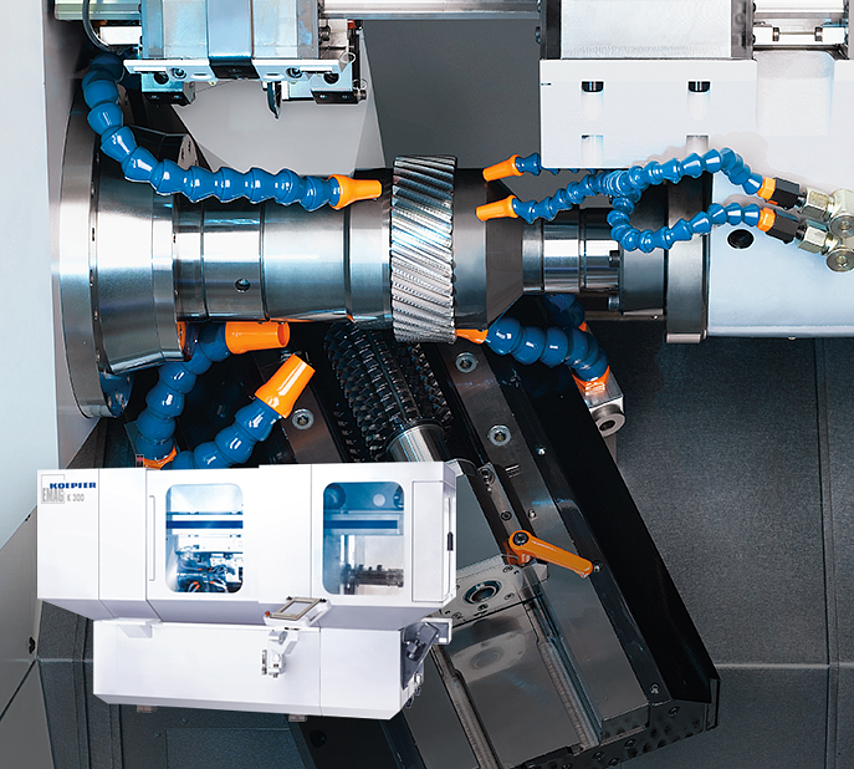

K 300 - Horizontal Hobbing on EMAG KOEPFER

Eliminate additional machines and processes by using the multi-functional EMAG Koepfer K 300 CNC-Machine. Complete a variety of gear cutting processes – gear hobbing, soft and hard machining, skiving, high speed hobbing, radial hobbing, tangential hobbing, etc. – on this customizable machine configured to your manufacturing requirements. The machine’s automatic loading system, equipped with V-grippers, can hold workpieces up to 5 kg in weight.

VL 3 DUO – Multi-Spindle Machines for High-Productive Manufacturing of Chucked Parts

The EMAG VL 3 DUO CNC Machine, is an efficient twin-spindle machine solution for chucked parts up to 150 mm in diameter. Since this turning machine is capable of several operations running simultaneously, fewer machining stations as well as operators not only save floor space, maintenance and labor costs, it also means fewer opportunities for machine operator errors and the associated expense.

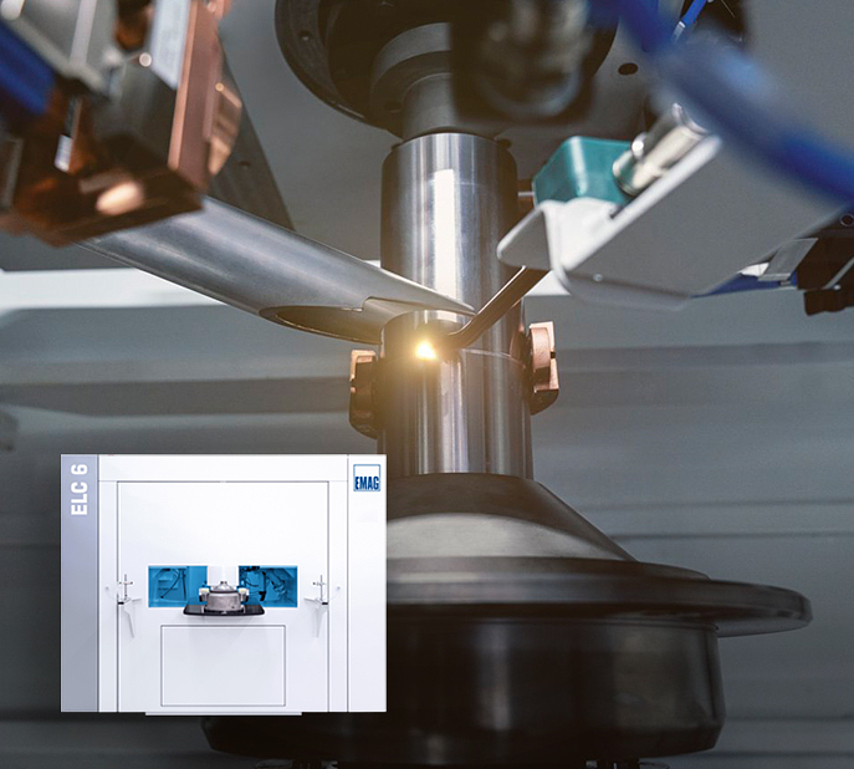

ELC 6 - Laser Welding Machine

Join, preheat and weld with the EMAG ELC 6, a production laser welding system for maximum output that is ideal for manufacturing powertrain components with round welds. The rotary table system as well as a loading and unloading station ensure optimum cycle times.

Come and visit us!

Experience our latest designs and developments live and see the performance and quality of our machines for yourself. We hope to see you in June and look forward to working with you to find the best solutions for your requirements.

Register now for your visit: