Stepped planetary gears are a key component in the drivetrains of electric vehicles. These components must meet high precision requirements while remaining cost-effective for series production. The combination of geometric complexity and tight tolerances demands sophisticated manufacturing concepts.

E-Mobility

Alexander Morhard, Technical Sales Support Manager at EMAG SU, talks in an interview about the G 160 gear generating grinding machine, the fastest machine of its kind for gear production. He provides insights into the innovative axis concept, the high gear quality and the wide range of possible applications in gear manufacturing and electromobility.

In the world of high precision drives, Zoerkler is a name synonymous with innovation, quality and technical excellence. In its almost 120-year history, the company has developed from a modest mechanical engineers’ workshop into a leading supplier of drive systems for the automotive and aviation industries. In this interview, Managing Director Bernhard Wagner provides insights into the fascinating world of precision manufacturing, innovative production technologies and the future visions of Zoerkler Gears GmbH & Co KG.

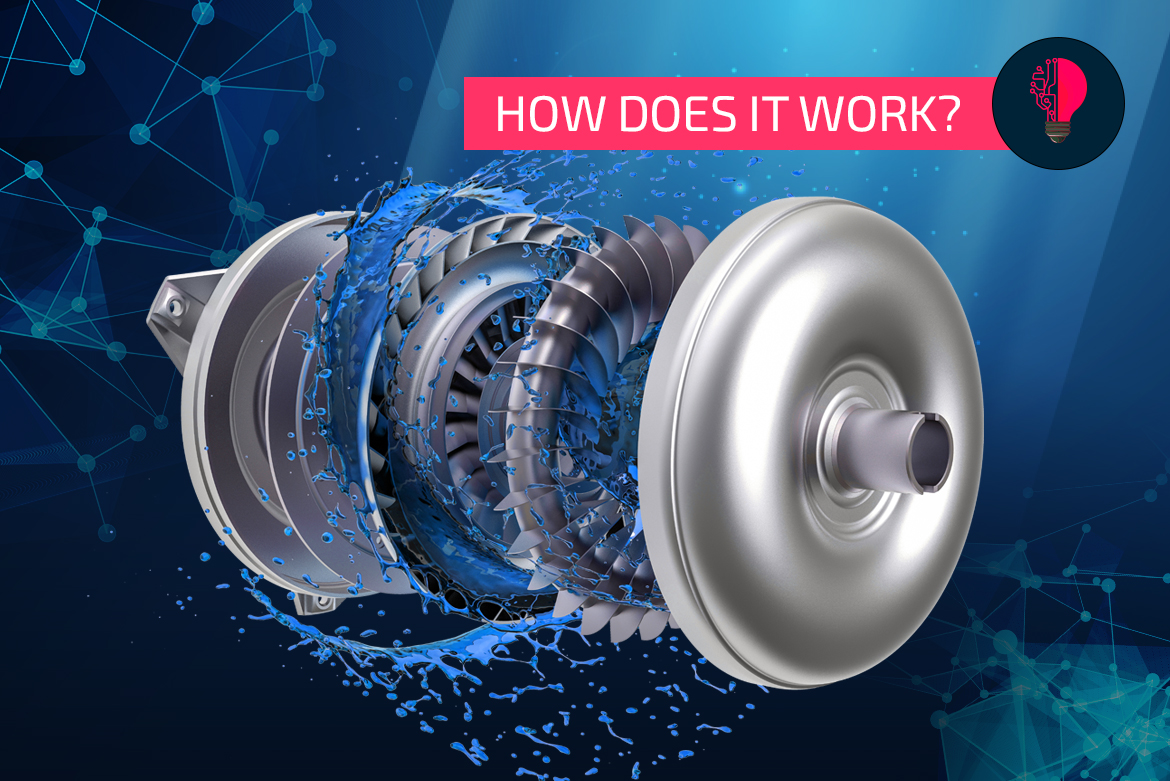

Old technology – new applications: The torque converter transmission is still “in” and is very important in automotive engineering. It is used more frequently in hybrid engines, for example. But how does the technology work and what are the advantages and disadvantages?

In the rapidly developing world of electromobility, precision and efficiency play a decisive role in production technology. The HLC 150 H high-performance gear cutting machine from EMAG KOEPFER represents a revolutionary solution in this context. This machine, which is characterized by its universality, precision and performance, was specially designed for the demanding task of machining tooth profiles in electric car components. With the increasing demand for quiet and efficient electric vehicles, the requirements for the machining quality of the components are also increasing. The HLC 150 H meets these challenges with advanced technology and an impressive range of machining options. In this blog post, we take a look at the special features and technical innovations of this machine and shed light on how it is driving production in the e-car sector.

The monthly number of new registrations of e-cars in Europe is currently increasing – and with it the required quantities for the e-drive components. The example of the supplier Linamar Technology Hungary shows how the production task behind this can be solved effectively. The e-drive specialists have recently invested in EMAG machines for the production of shafts and gears. A conversation with István Bíró, Project leader at Linamar Technology Hungary, about the new solution at the site in Békécsaba.

As a mechanical engineering company, EMAG is making an important contribution to establishing electromobility: The specialists are developing the production technology that can manufacture central components of the electric motor – on a turnkey basis. A new production line for the rotor shaft of electric cars used by a German components supplier illustrates their approach. The solution was delivered at the end of last year. Here we have a conversation with Andreas Bucher, Key Account Manager at EMAG, and Michael Ihring from EMAG Systems about the reasons for this cooperation.

Particular precision is essential for the e-drive market: Many components require perfect surfaces – this ensures smooth running at the high torques of the electric motor. The example of “tooth flank grinding” with machines from EMAG SU shows how suppliers, general transmission manufacturers and OEMs can implement this requirement: The grinding specialists have, for example, a special axis concept in the G 160 machine that guarantees microscopically perfect surfaces. A conversation with Alexander Morhard from EMAG SU about EMAG SU’s mechanical engineering solutions for tooth flank grinding.

How stable is the current growth in the construction and utility vehicle industries?

Whether excavators, trucks or buses – the market for construction machinery and utility vehicles has been on the upswing for a while now. Where does this success come from and what role will electric drives play in the future? We will examine this by exploring the current situation.

In the past year, for the first time ever, more than 2 million electric vehicles were sold worldwide as reported by the Center of Automotive Management (CAM). With 60% of the worldwide demand, China is the main driver of this development.

- 1

- 2