ECM is an innovative technology for machining the barrels of sporting guns. A special rifling module is used in the PI machine. The result is a highly precise and homogeneous field rifling profile for short and long barrels.

Gentle removal of hard materials, plus no thermal or mechanical stresses – ECM rifling ensures perfect processes in the production of gun barrels.

High-precision barrels guaranteed

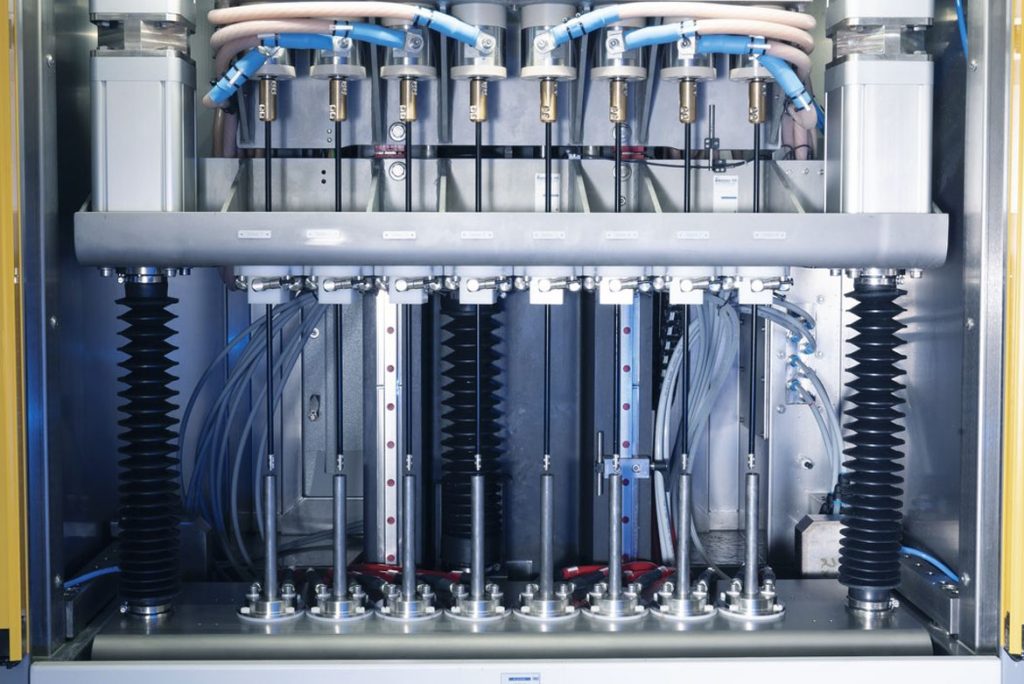

A sophisticated concept is used specifically for this application: inside a PI machine there is a module that can accommodate up to eight tool cathodes and eight components.

Rifling module – Up to eight components are machined in parallel.

The process is faster than alternatives,, such as hammering or drawing and is more economical in terms of costs. The operator inserts up to eight blanks with finished external geometry, which are only deep-hole drilled, into the workpiece holders and starts the process.

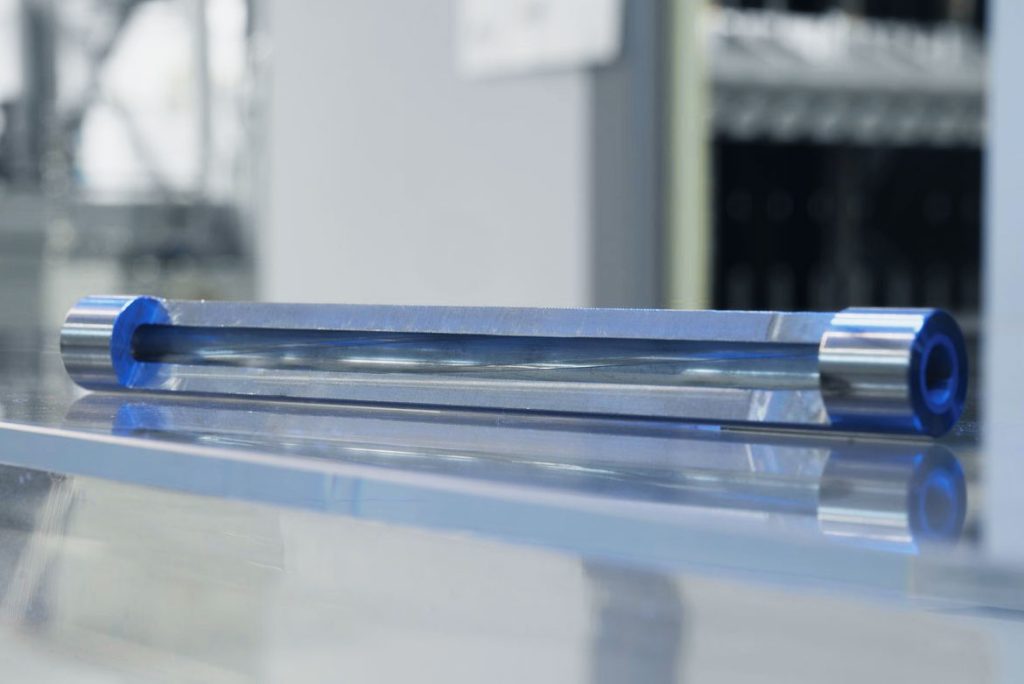

Important here: The tool cathode reproduces the desired internal geometry of the barrel with high precision, whereby very different geometries such as “polygon”, “progressive” or “standard” are conceivable.

ECM rifling – Rapid processes: The solution is suitable for short and long barrels and almost any internal geometry.

The solution is also suitable for short and long barrels. The low tool wear ensures extreme repeat accuracy in every case.

The advantages

- Low capital investments compared to hammering

- Parallel machining for short cycle times

- No subsequent soft annealing necessary

- Quick tool change

- Almost any interior geometry can be acheived

- No mechanical or thermal stresses on the component

- No vibrations in production

- Quiet process

- Minimal footprint

- Low unit production costs